Secondary Chilled Water Loop Setpoint can't be controlled

There is a similar post in the past, but that answer did not to work.

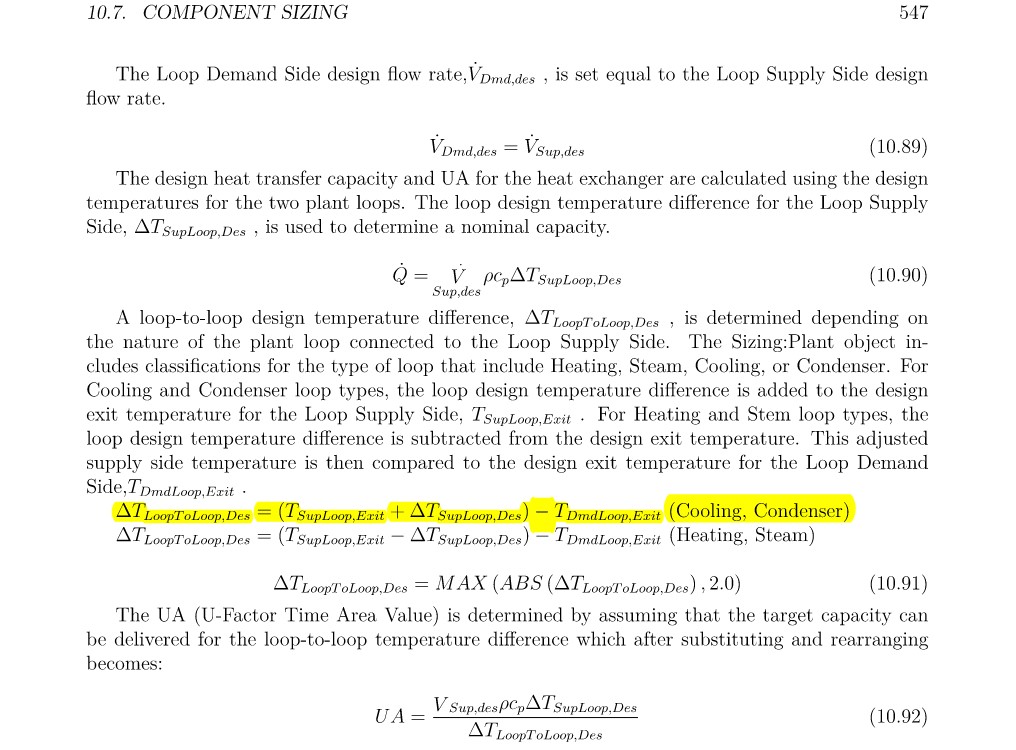

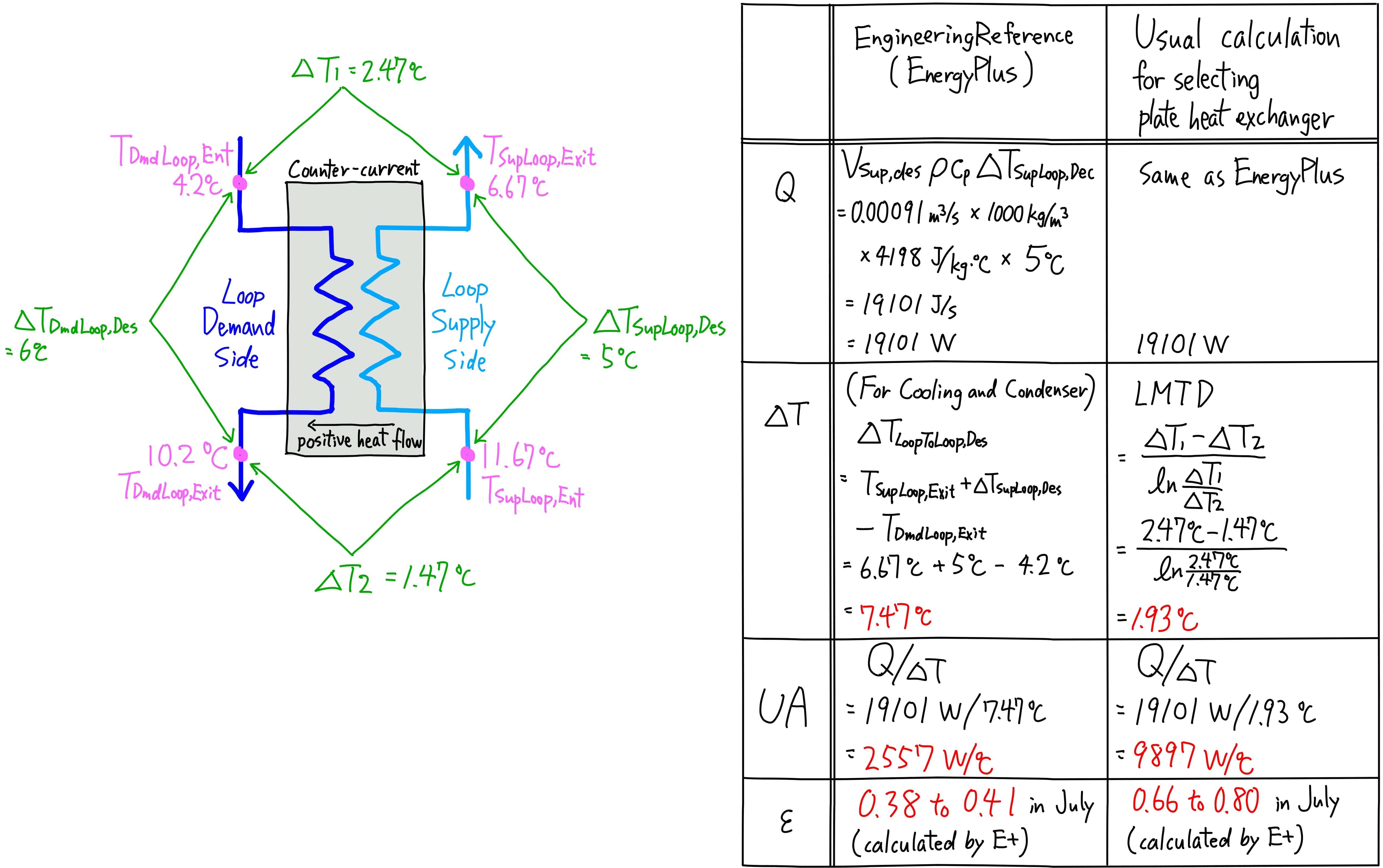

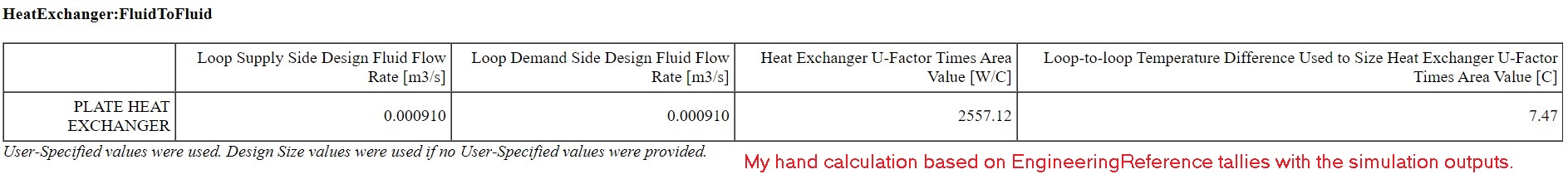

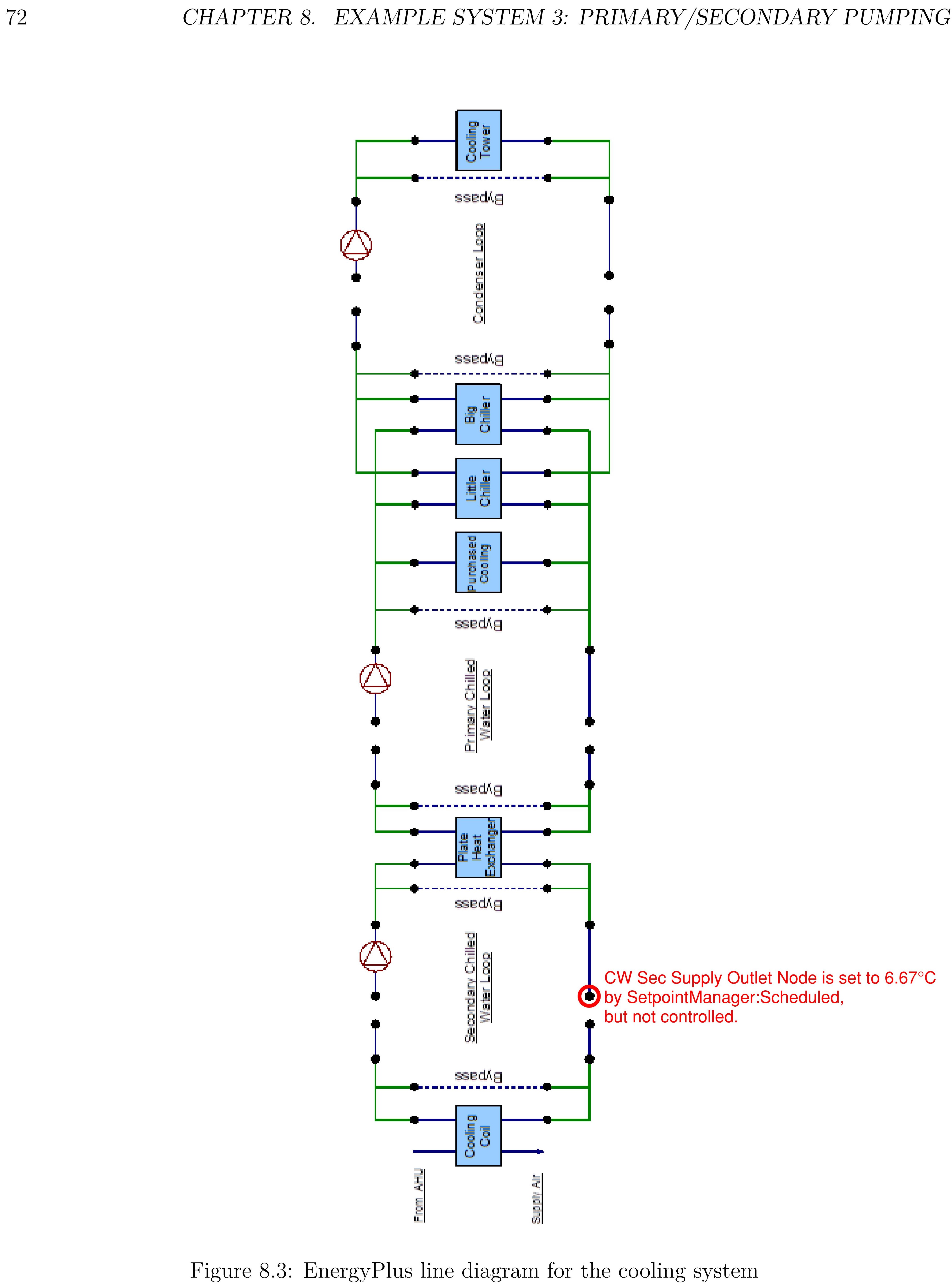

PlantApplicationsGuide_Example3.idf is one of ExampleFiles for EnergyPlus. It has Primary/Secondary Chilled Water Loop connencted through HeatExchanger:FluidToFluid.

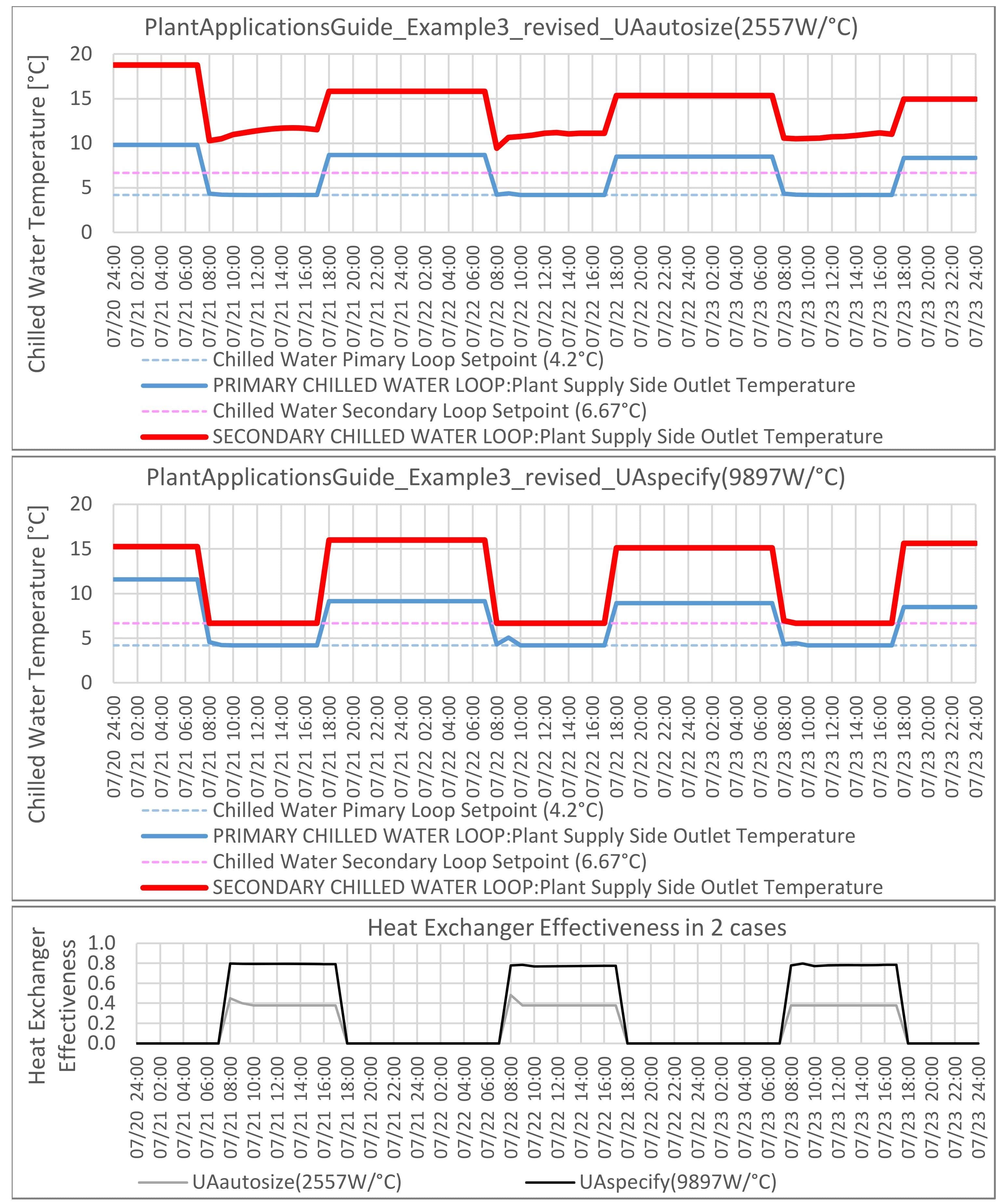

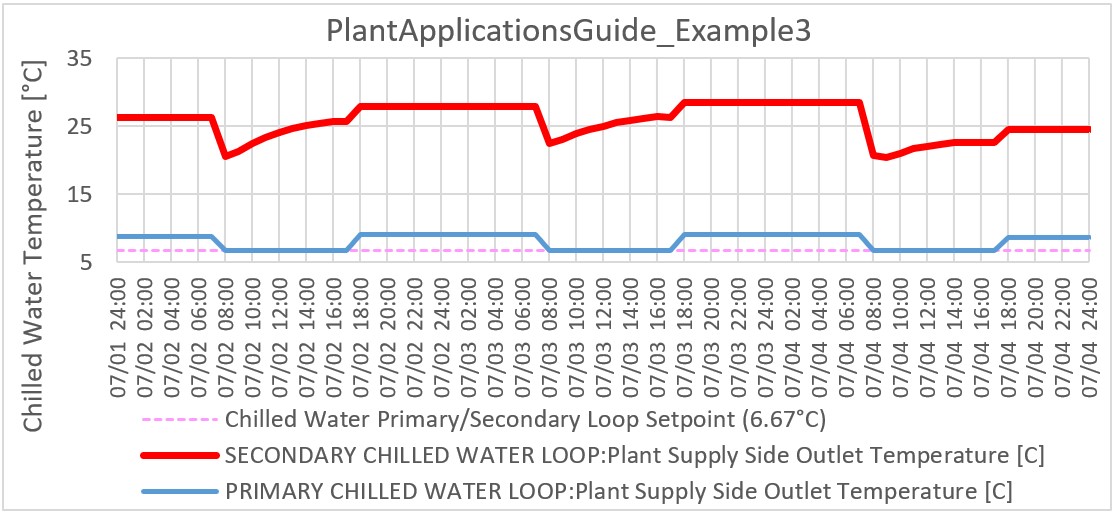

CW Sec Supply Outlet Node is set to 6.67°C by SetpointManager:Scheduled, but actually it's not controlled and it's around 20 to 27°C,which is much higher than the setpoint of 6.67°C.

Does anyone know how to control this supply outlet temperature of secondary chilled water loop as desired?

Originally, Control Type of HeatExchanger:FluidToFluid is UncontrolledOn, so I changed it to CoolingSetpointModulated and input Heat Exchanger Setpoint Node Name, but in vain.

I tried the following changes, but none of them worked.

- Increased Chiller

Nominal Capacityand PumpDesign Maximum Flow Rate. - Set EMS to override the

Temperature Setpoint. - Changed the

Temperature Setpointhigher thanTemperature Setpointof primary chilled water loop supply outlet.

Not only this example file, but also other my own model that uses HeatExchanger:FluidToFluid has similar Uncontrolled Temperature problem (but my model is a bit complicated, so I explained the problem with ExampleFile). Any insights would be appreciated.