I using Energyplus to simulate two equal capacity chillers autosized to meet the cooling load for an office. I already read this question and I checked my IDF based on it: 1- I sized my chillers using autosize and size factor of 0.5

Chiller:Electric:ReformulatedEIR,

CoolSys1 Chiller1, !- Name

autosize, !- Reference Capacity {W}

6.28, !- Reference COP {W/W}

6.6700, !- Reference Leaving Chilled Water Temperature {C}

34.4444, !- Reference Leaving Condenser Water Temperature {C}

autosize, !- Reference Chilled Water Flow Rate {m3/s}

autosize, !- Reference Condenser Water Flow Rate {m3/s}

WC_CENT_2010_PB_CAPFT, !- Cooling Capacity Function of Temperature Curve Name

WC_CENT_2010_PB_EIRFT, !- Electric Input to Cooling Output Ratio Function of Temperature Curve Name

LeavingCondenserWaterTemperature, !- Electric Input to Cooling Output Ratio Function of Part Load Ratio Curve Type

WC_CENT_300to600_2010_PB_EIRFPLR, !- Electric Input to Cooling Output Ratio Function of Part Load Ratio Curve Name

0.1000, !- Minimum Part Load Ratio

1.0000, !- Maximum Part Load Ratio

1.0000, !- Optimum Part Load Ratio

0.1000, !- Minimum Unloading Ratio

CoolSys1 Pump-CoolSys1 Chiller1Node, !- Chilled Water Inlet Node Name

CoolSys1 Supply Equipment Outlet Node 1, !- Chilled Water Outlet Node Name

CoolSys1 Chiller1 Water Inlet Node, !- Condenser Inlet Node Name

CoolSys1 Chiller1 Water Outlet Node, !- Condenser Outlet Node Name

, !- Fraction of Compressor Electric Consumption Rejected by Condenser

5.0000, !- Leaving Chilled Water Lower Temperature Limit {C}

ConstantFlow, !- Chiller Flow Mode Type

0.0000, !- Design Heat Recovery Water Flow Rate {m3/s}

, !- Heat Recovery Inlet Node Name

, !- Heat Recovery Outlet Node Name

0.5; !- Sizing Factor

2- I used the operation scheme objects to specify the priority of using chillers.

PlantEquipmentOperationSchemes,

CoolSys1 Loop Operation Scheme List, !- Name

PlantEquipmentOperation:CoolingLoad, !- Control Scheme 1 Object Type

CoolSys1 Operation Scheme, !- Control Scheme 1 Name

PlantOnSched; !- Control Scheme 1 Schedule Name

PlantEquipmentOperation:CoolingLoad,

CoolSys1 Operation Scheme, !- Name

0, !- Load Range 2 Lower Limit {W}

100000000000000, !- Load Range 2 Upper Limit {W}

CoolSys1 Equipment List 2; !- Range 2 Equipment List Name

PlantEquipmentList,

CoolSys1 Equipment List 2, !- Name

Chiller:Electric:ReformulatedEIR, !- Equipment 1 Object Type

CoolSys1 Chiller1, !- Equipment 1 Name

Chiller:Electric:ReformulatedEIR, !- Equipment 2 Object Type

CoolSys1 Chiller2; !- Equipment 2 Name

3- I used the load distribution scheme in the plant loop definition:

PlantLoop,

CoolSys1_Demand, !- Name

Water, !- Fluid Type

, !- User Defined Fluid Type

CoolSys1 Sec Loop Operation, !- Plant Equipment Operation Scheme Name

CoolSys1 Demand Inlet Node, !- Loop Temperature Setpoint Node Name

98, !- Maximum Loop Temperature {C}

1, !- Minimum Loop Temperature {C}

autosize, !- Maximum Loop Flow Rate {m3/s}

0, !- Minimum Loop Flow Rate {m3/s}

autocalculate, !- Plant Loop Volume {m3}

CoolSys1 Demand Supply Side Inlet Pipe Inlet Node, !- Plant Side Inlet Node Name

CoolSys1 Demand Supply Side Outlet Pipe Outlet Node, !- Plant Side Outlet Node Name

CoolSys1 Demand Supply Side Branches, !- Plant Side Branch List Name

CoolSys1 Demand Supply Side Connectors, !- Plant Side Connector List Name

CoolSys1 Demand Inlet Node, !- Demand Side Inlet Node Name

CoolSys1 Demand Outlet Node, !- Demand Side Outlet Node Name

CoolSys1 Demand Demand Side Branches, !- Demand Side Branch List Name

CoolSys1 Demand Demand Side Connectors, !- Demand Side Connector List Name

SequentialLoad; !- Load Distribution Scheme

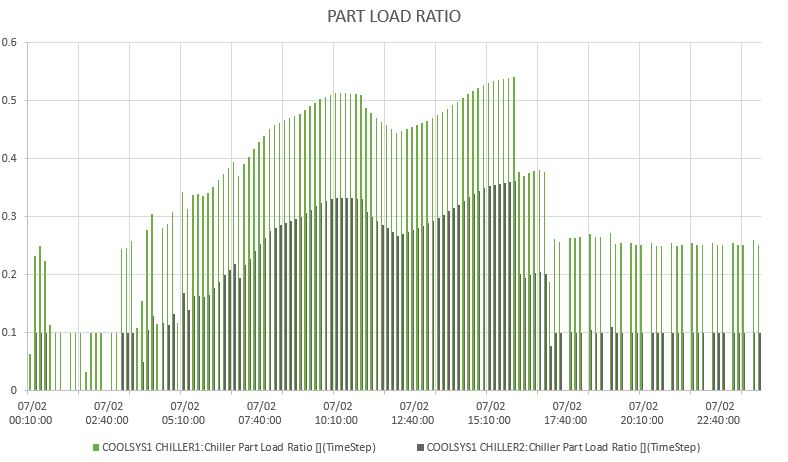

When I run the simulation for a day I receive weird load distribution as follow:

As can be seen, the first chiller doesn't reach its maximum PLR!!

I tried many modifications but no matter what, the load distribution doesn't work properly. Here is my idf file.

As can be seen, the first chiller doesn't reach its maximum PLR!!

I tried many modifications but no matter what, the load distribution doesn't work properly. Here is my idf file.