On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow. Can someone show a model in open studio using Low Temp Radiant Const Flow?

First time here? Check out the Help page!

| 1 | initial version |

On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow. Can someone show a model in open studio using Low Temp Radiant Const Flow?

| 2 | retagged |

On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow. Can someone show a model in open studio using Low Temp Radiant Const Flow?

On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow. Can someone show a model in open studio using Low Temp Radiant Const Flow?

On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow.

Flow.

Can someone show a tell me why my program failed and how to do it properly?

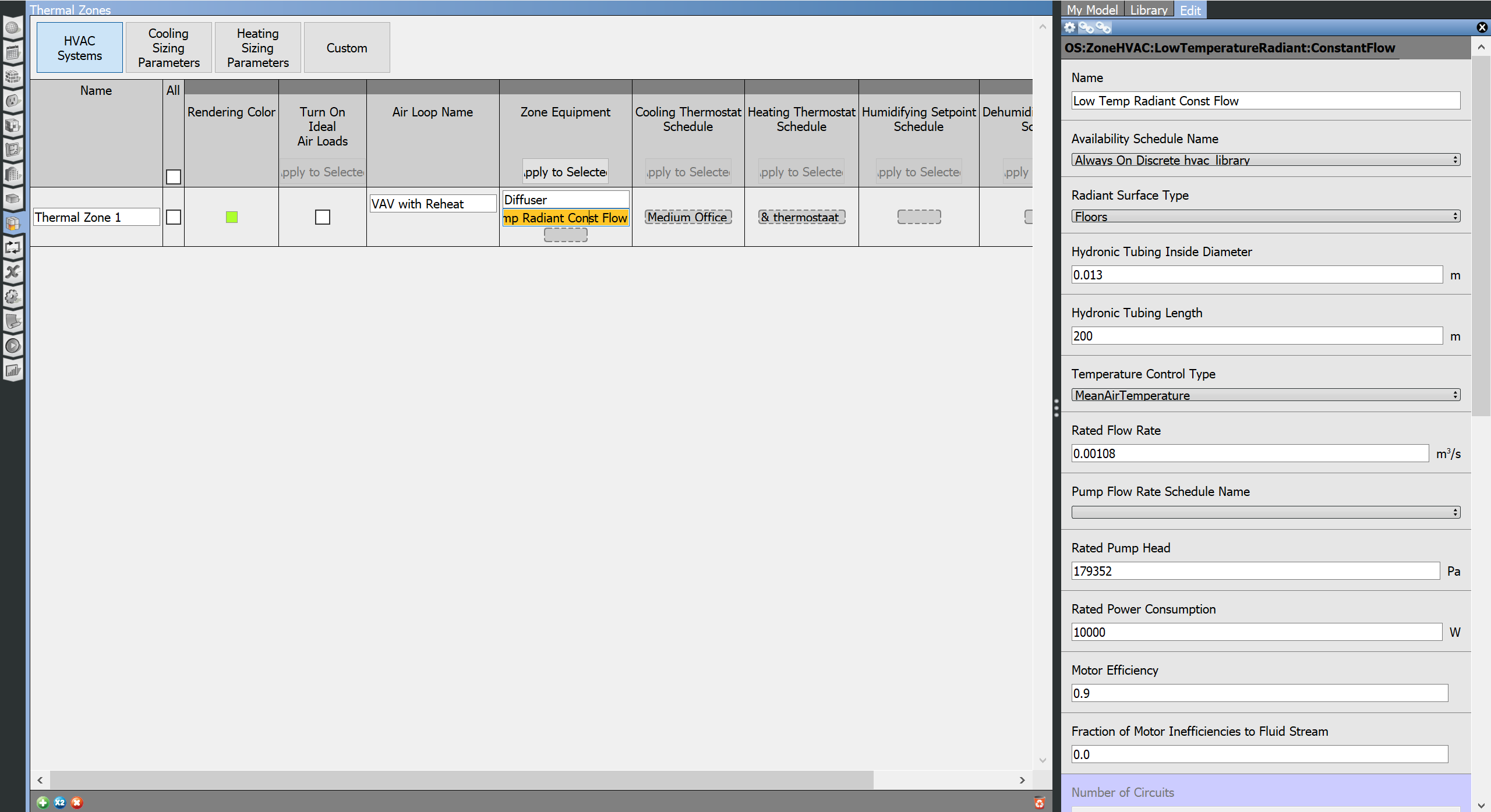

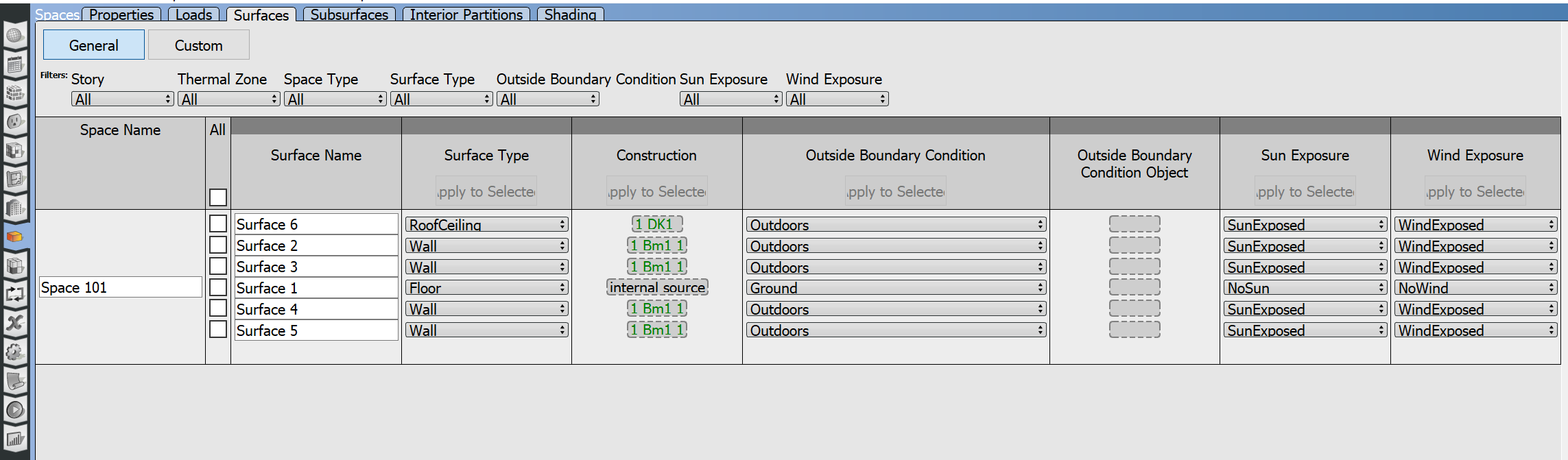

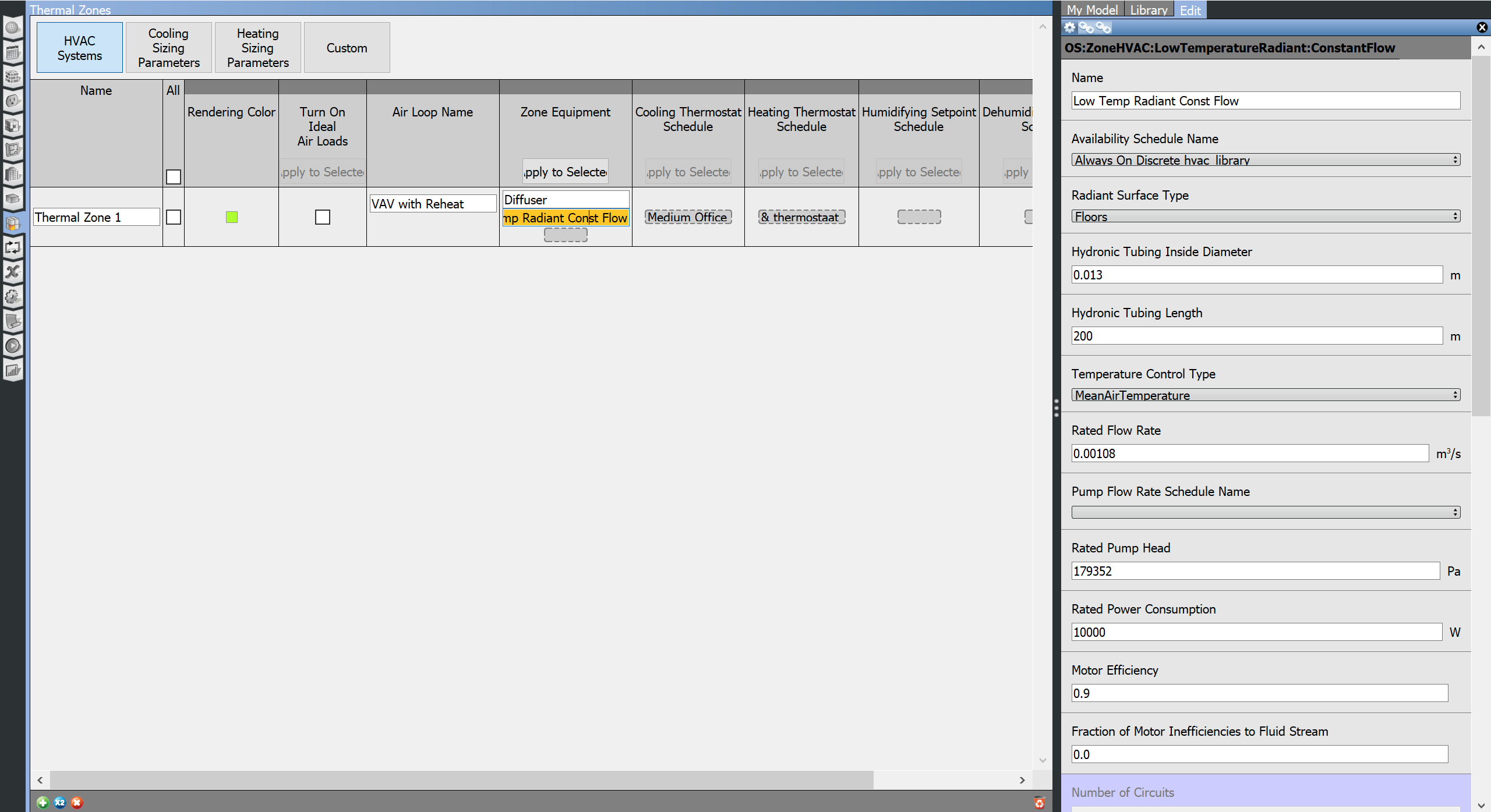

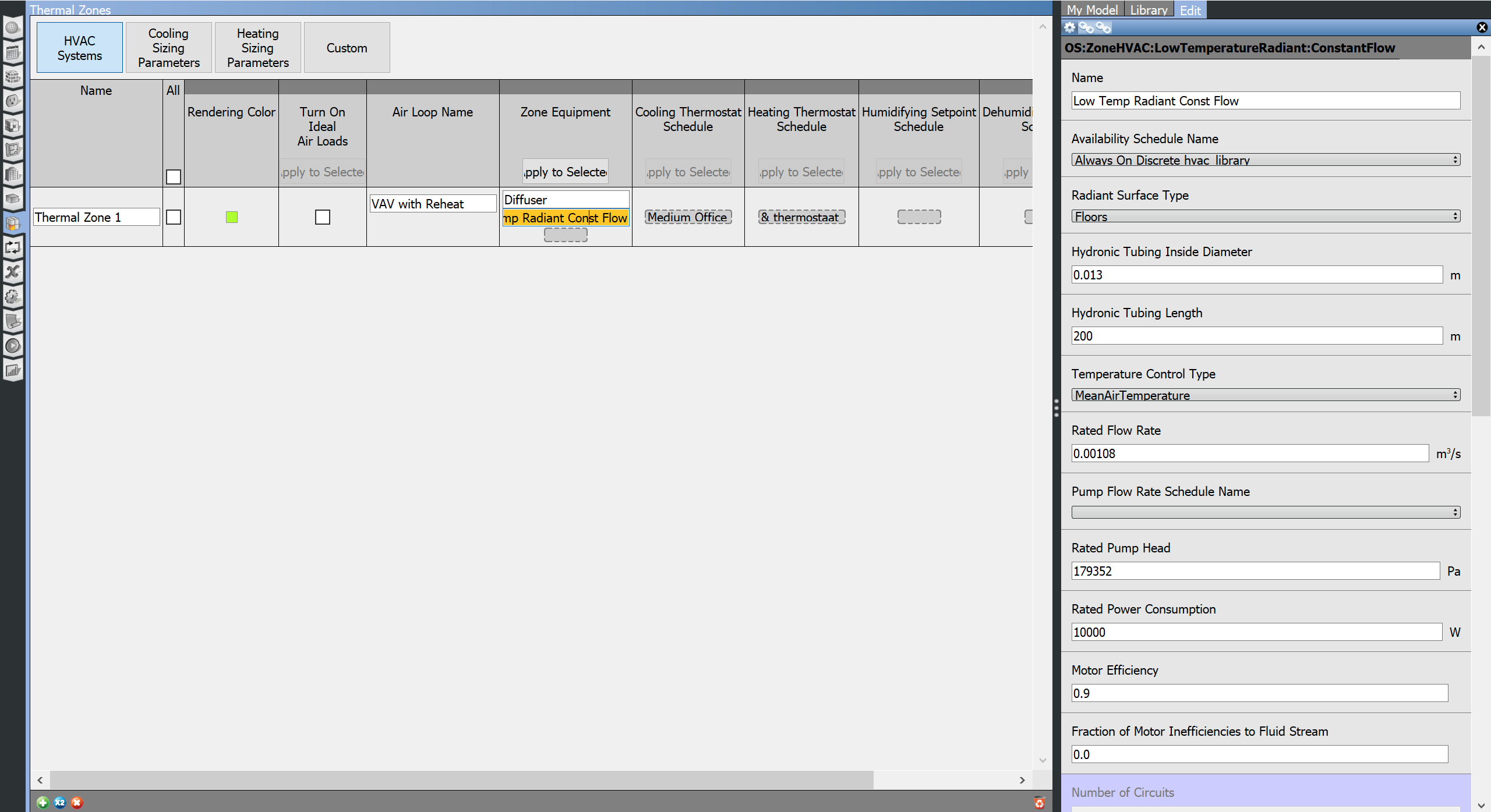

here are some photos in openstudio: C:\fakepath\foto 1.png C:\fakepath\foto 2.png C:\fakepath\foto 3.png C:\fakepath\foto 4.png C:\fakepath\foto 5.png C:\fakepath\foto 6.png

I use the low temperature to model in open studio floor heating.

some information about the floor heating:

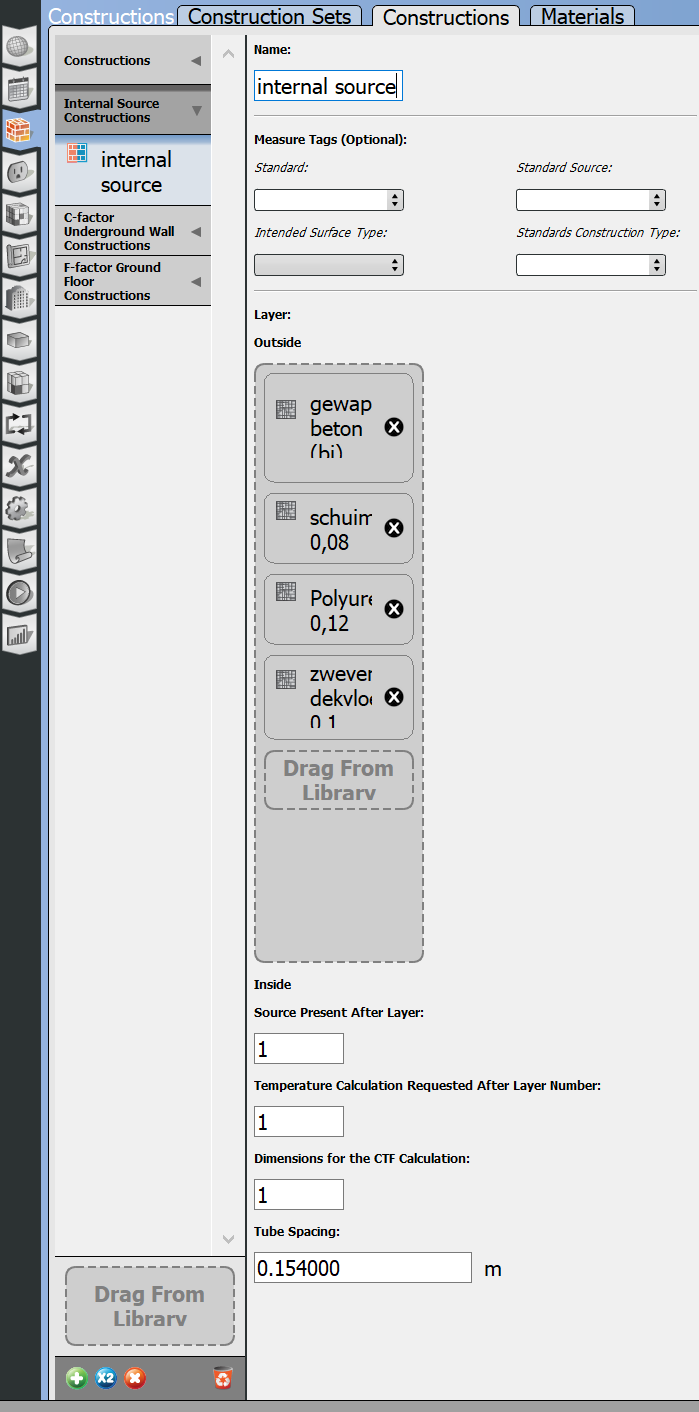

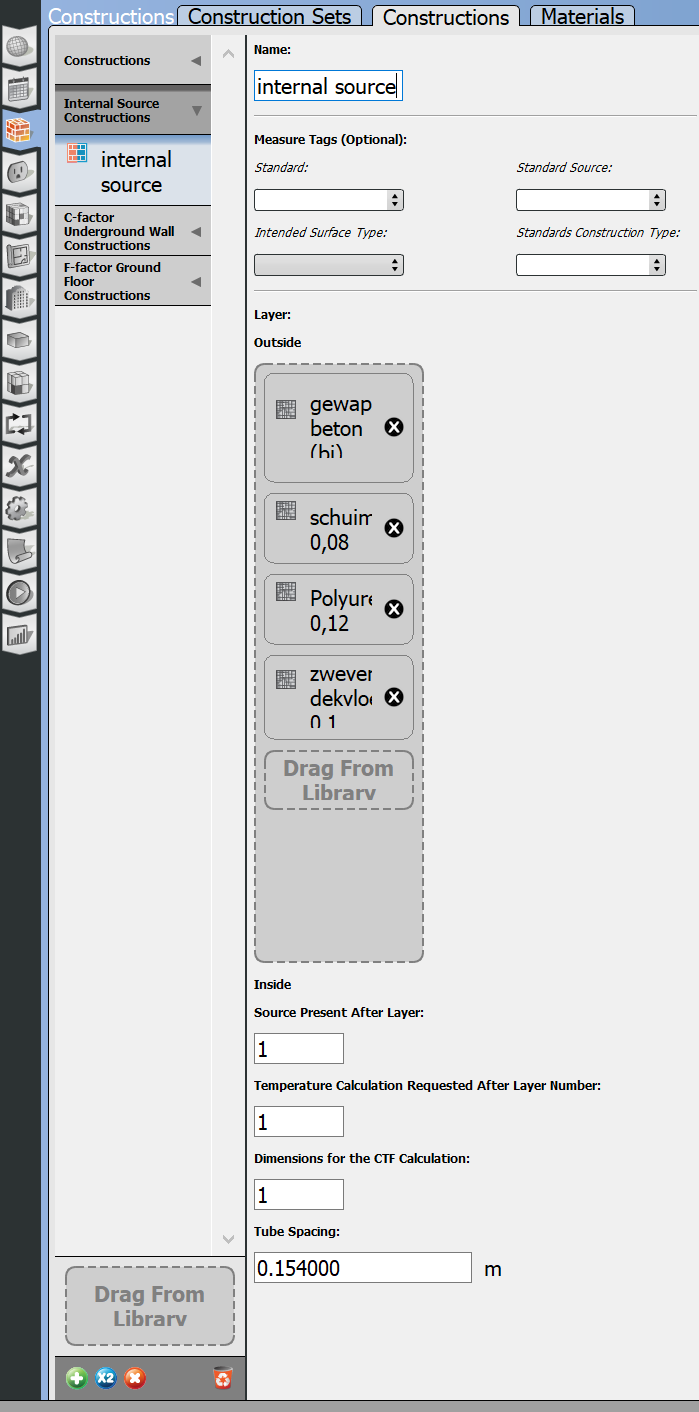

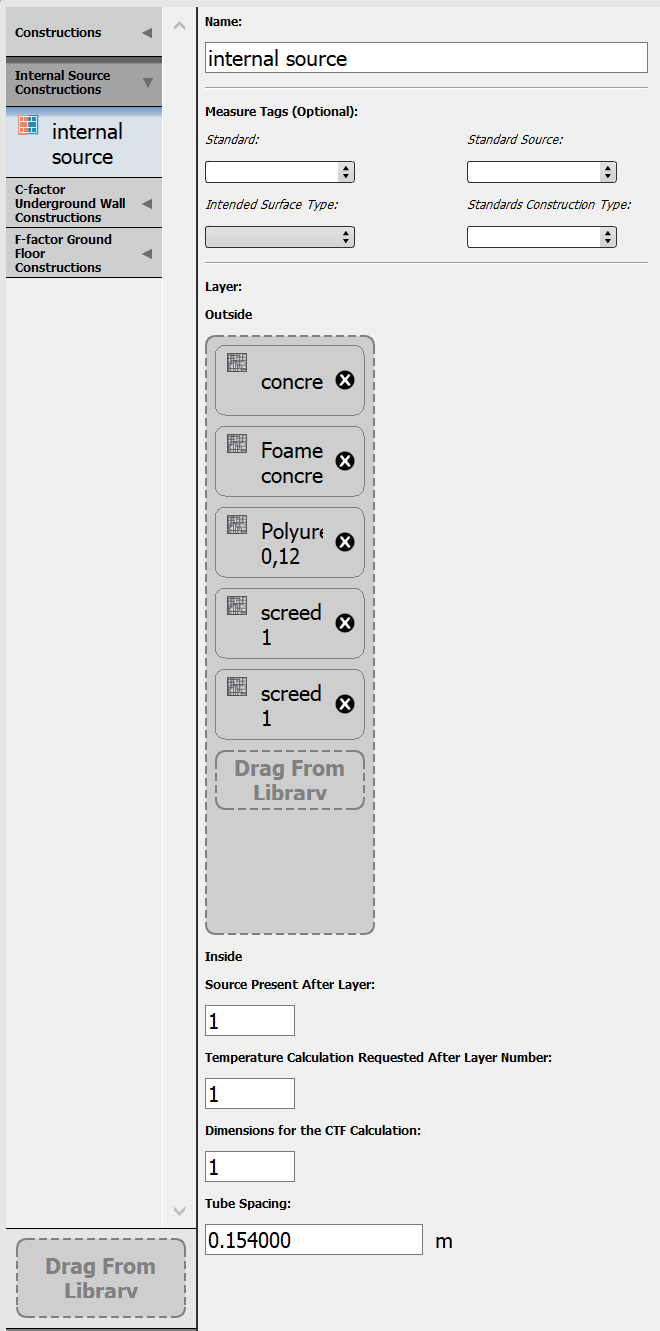

constant temperature of 21 ° C my Internal source layer consists of: reinforced concrete / foam / polyurethane / floating screed (you can see this on the photo)

This is the error that I get when using Low Temp Radiant Const Flow?Flow

On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow.

Can someone tell me why my program failed and how to do it properly?

here are some photos in openstudio: C:\fakepath\foto 1.png C:\fakepath\foto 2.png C:\fakepath\foto 3.png C:\fakepath\foto 4.png C:\fakepath\foto 5.png C:\fakepath\foto 6.png

I use the low temperature to model floor heating.

some heating.

Some information about the floor heating:

constant temperature of 21 ° C my Internal source layer consists of: reinforced concrete / foam / polyurethane / floating screed (you can see this on the photo)

This is the error that I get when using Low Temp Radiant Const Flow

On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow.

Can someone tell me why my program failed and how to do it properly?

here are some photos in openstudio: C:\fakepath\foto 1.png C:\fakepath\foto 2.png C:\fakepath\foto 3.png C:\fakepath\foto 4.png C:\fakepath\foto 5.png C:\fakepath\foto 6.png

I use the low temperature to model floor heating.

Some information about the floor heating:

This is the error that I get when using Low Temp Radiant Const Flow

| 7 | None |

On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow.

Can someone tell me why my program failed and how to do it properly?

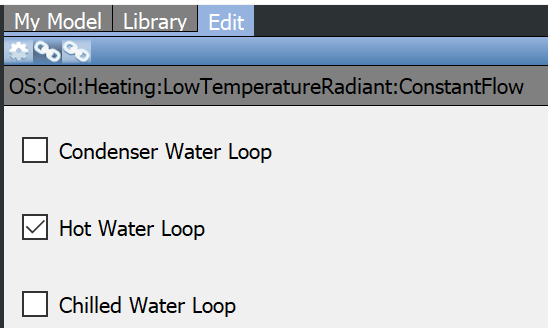

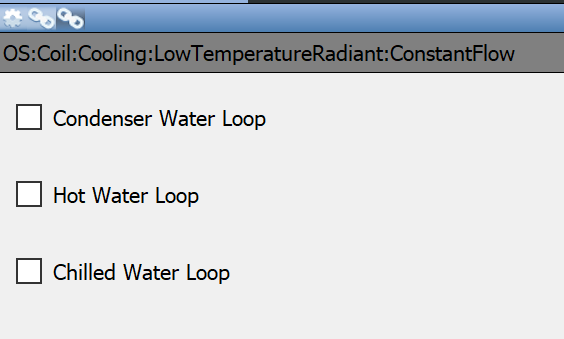

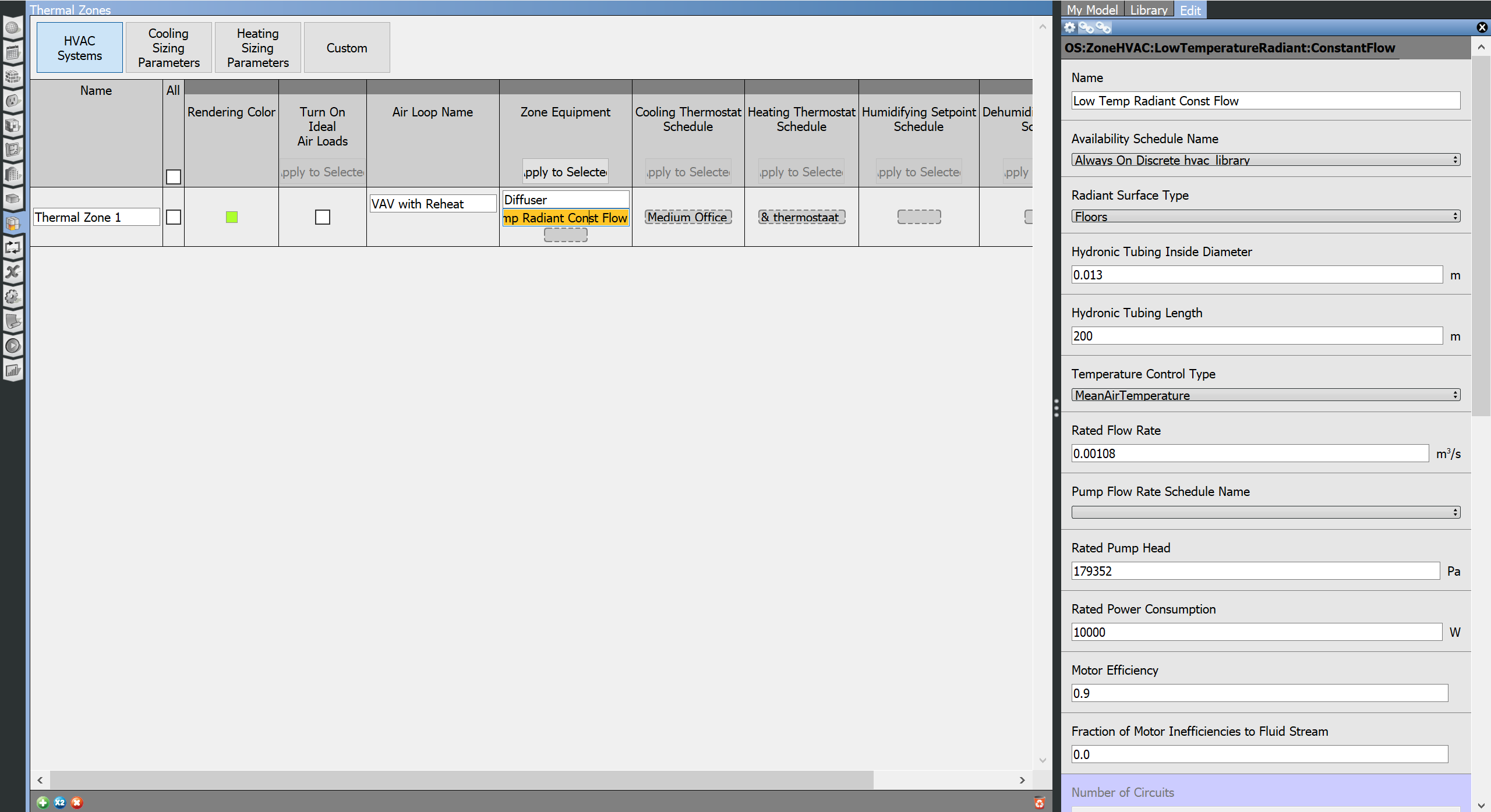

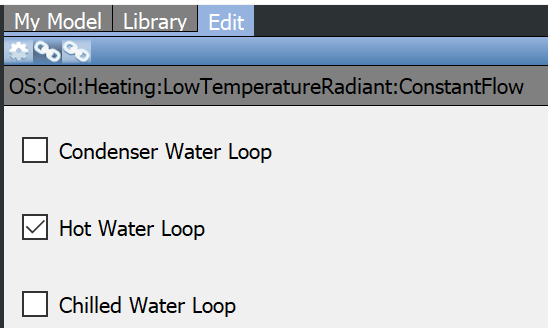

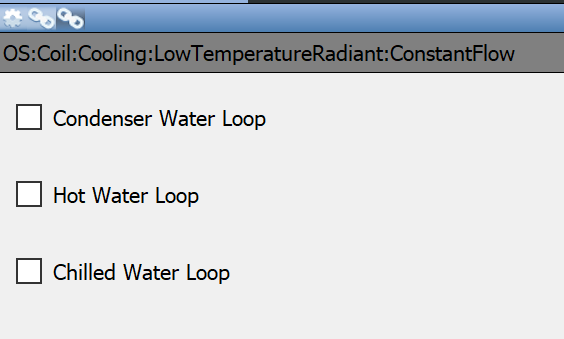

here are some photos in openstudio:

C:\fakepath\foto 1.png C:\fakepath\foto 2.png C:\fakepath\foto 3.png C:\fakepath\foto 4.png C:\fakepath\foto 5.png C:\fakepath\foto 6.png

I use the low temperature to model floor heating.

Some information about the floor heating:

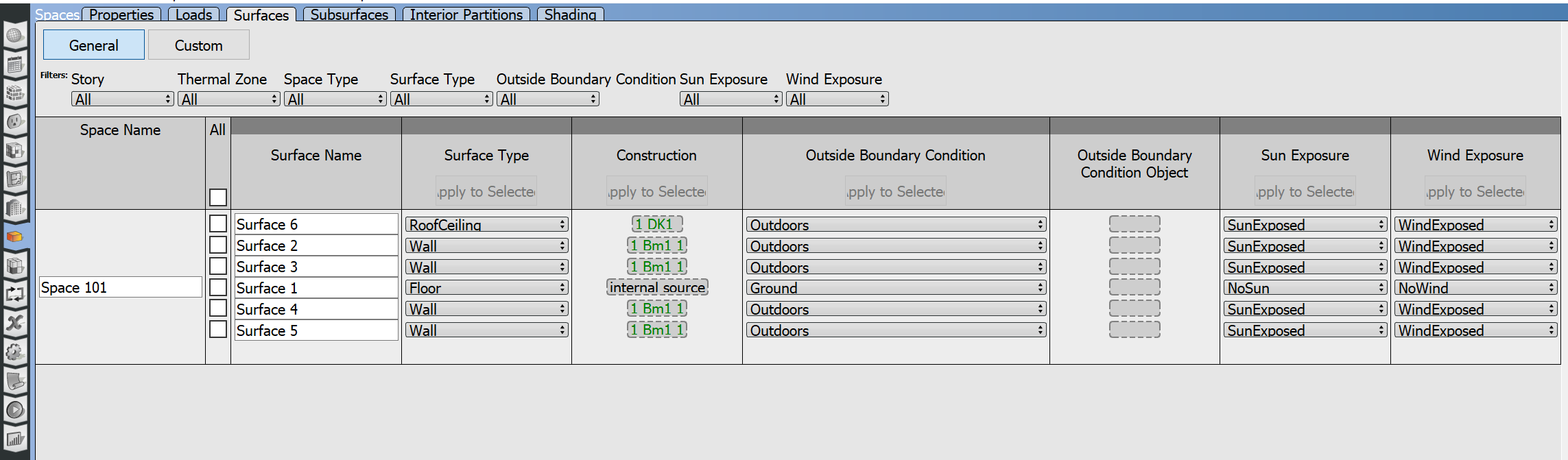

my Internal source layer consists of (you can see this on the photo):

reinforced concrete / foam / polyurethane / floating screed

here are some photos in openstudio:

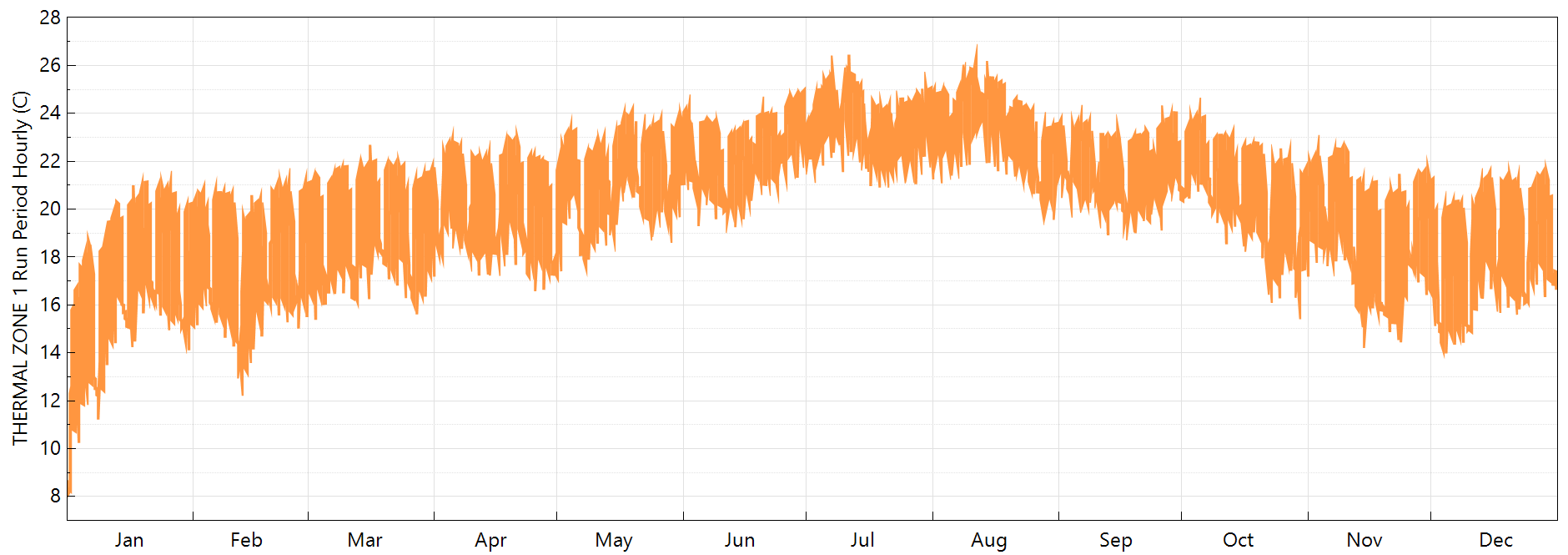

This is the error that I get when using Low Temp Radiant Const Flow

* On this forum I have already read several articles on this topic. But I can't help it. My program failed every time I implement the Low Temp Radiant Const Flow.

Can someone tell me why my program failed and how to do it properly?

I use the low temperature to model floor heating.

Some information about the floor heating:

my Internal source layer consists of (you can see this on the photo):

reinforced concrete / foam / polyurethane / floating screed

here are some photos in openstudio:

This is the error that I get when using Low Temp Radiant Const Flow

* Warning * Check input. Calc Pump Efficiency=2.15222E-002% which is less than 50%, for pump in radiant system LOW TEMP RADIANT CONST FLOW *** Beginning Plant Sizing Calculations * Warning * GetOAControllerInputs: Controller:MechanicalVentilation="CONTROLLER MECHANICAL VENTILATION 1 * ~~~ * Cannot locate a matching DesignSpecification:OutdoorAir object for Zone="THERMAL ZONE 1". * ~~~ * Using default OA of 0.00944 m3/s-person and 0.0 m3/s-m2. * Severe * Controller:MechanicalVentilation="CONTROLLER MECHANICAL VENTILATION 1", Design Specification Outdoor Air Object Name blank * ~~~ * For Zone="THERMAL ZONE 1". * ~~~ * This field either needs to be filled in in this object or Sizing:Zone object. * ~~~ * For this run, default values for these fields will be used. * Warning * Controller:MechanicalVentilation = "CONTROLLER MECHANICAL VENTILATION 1", Zone="THERMAL ZONE 1". * ~~~ * No "PEOPLE" object has been specified in the idf for this zone, but the ventilation rate is > 0 in this Controller:MechanicalVentilation Object. * ~~~ * Check ventilation rate in Controller:MechanicalVentilation object. Simulation will continue. * Warning * Output:Meter: invalid Key Name="DISTRICTCOOLING:FACILITY" - not found. * Warning * Output:Meter: invalid Key Name="DISTRICTHEATING:FACILITY" - not found. * Warning * Output:Meter:MeterFileOnly requested for "Electricity:Facility" (TimeStep), already on "Output:Meter". Will report to both eplusout.eso and eplusout.mtr *** Testing Individual Branch Integrity *** All Branches passed integrity testing *** Testing Individual Supply Air Path Integrity *** All Supply Air Paths passed integrity testing *** Testing Individual Return Air Path Integrity *** All Return Air Paths passed integrity testing *** No node connection errors were found. *** Beginning Simulation * Warning * GetSpecificHeatGlycol: Temperature is out of range (too high) for fluid [WATER] specific heat * * ~~~ * ..Called From:CalcSimpleHeatingCoil,Temperature=[137.06], supplied data range=[0.00,125.00] * ~~~ * Environment=BRUSSELS ANN HTG WIND 99.6% CONDNS WS=>MCDB, at Simulation time=01/21 00:00 - 00:10 * Warning * GetDensityGlycol: Temperature is out of range (too high) for fluid [WATER] density * * ~~~ * ..Called From:PlantPumps:CalcPumps: ,Temperature=[137.12], supplied data range=[0.00,100.00] * ~~~ * Environment=BRUSSELS ANN HTG WIND 99.6% CONDNS WS=>MCDB, at Simulation time=01/21 00:00 - 00:10 * Severe * Plant temperatures are getting far too hot, check controls and relative loads and capacities * ~~~ * Environment=RUN PERIOD 1, at Simulation time=05/20 20:40 - 20:50 * ~~~ * PlantLoop Name (SupplySide)= HOT WATER LOOP * ~~~ * PlantLoop Setpoint Temperature=67.0 {C} * ~~~ * PlantLoop Inlet Node (SupplySide) does not have a Setpoint. * ~~~ * PlantLoop Inlet Node (DemandSide) does not have a Setpoint. * ~~~ * PlantLoop Outlet Node (SupplySide) has a Setpoint. * ~~~ * PlantLoop Outlet Node (DemandSide) does not have a Setpoint. * ~~~ * PlantLoop Outlet Node (SupplySide) "NODE 13" has temperature=300.0 {C} * ~~~ * PlantLoop Inlet Node (SupplySide) "NODE 12" has temperature=300.0 {C} * ~~~ * PlantLoop Minimum Temperature=0.0 {C} * ~~~ * PlantLoop Maximum Temperature=100.0 {C} * ~~~ * PlantLoop Flow Request (SupplySide)=0.0 {kg/s} * ~~~ * PlantLoop Flow Request (DemandSide)=1.1 {kg/s} * ~~~ * PlantLoop Node (SupplySide) "NODE 13" has mass flow rate =1.1 {kg/s} * ~~~ * PlantLoop PumpHeat (SupplySide)=252.0 {W} * ~~~ * PlantLoop PumpHeat (DemandSide)=0.0 {W} * ~~~ * PlantLoop Cooling Demand=1049914.2 {W} * ~~~ * PlantLoop Heating Demand=0.0 {W} * ~~~ * PlantLoop Demand not Dispatched=0.0 {W} * ~~~ * PlantLoop Unmet Demand=-1049914.2 {W} * ~~~ * PlantLoop Capacity=49598.3 {W} * ~~~ * PlantLoop Capacity (SupplySide)=49598.3 {W} * ~~~ * PlantLoop Capacity (DemandSide)=0.0 {W} * ~~~ * PlantLoop Operation Scheme=HOT WATER LOOP OPERATION SCHEMES * ~~~ * PlantLoop Operation Dispatched Load = 0.0 {W} * ~~~ * PlantLoop Operation Dispatched Load (SupplySide)= 0.0 {W} * ~~~ * PlantLoop Operation Dispatched Load (DemandSide)= 0.0 {W} * ~~~ * Branches on the Loop. * ~~~ * Demand Branches: * ~~~ * HOT WATER LOOP DEMAND INLET BRANCH * ~~~ * Components on Branch: * ~~~ * PIPE:ADIABATIC:PIPE ADIABATIC 3 * ~~~ * HOT WATER LOOP DEMAND BRANCH 1 * ~~~ * Components on Branch: * ~~~ * PIPE:ADIABATIC:PIPE ADIABATIC 2 * ~~~ * HOT WATER LOOP DEMAND BRANCH 2 * ~~~ * Components on Branch: * ~~~ * COIL:HEATING:WATER:COIL HEATING WATER 1 * ~~~ * HOT WATER LOOP DEMAND BRANCH 3 * ~~~ * Components on Branch: * ~~~ * ZONEHVAC:LOWTEMPERATURERADIANT:CONSTANTFLOW:LOW TEMP RADIANT CONST FLOW * ~~~ * HOT WATER LOOP DEMAND BYPASS BRANCH * ~~~ * Components on Branch: * ~~~ * PIPE:ADIABATIC:HOT WATER LOOP DEMAND BYPASS PIPE * ~~~ * HOT WATER LOOP DEMAND OUTLET BRANCH * ~~~ * Components on Branch: * ~~~ * PIPE:ADIABATIC:PIPE ADIABATIC 4 * ~~~ * Supply Branches: * ~~~ * HOT WATER LOOP SUPPLY INLET BRANCH * ~~~ * Components on Branch: * ~~~ * PUMP:VARIABLESPEED:PUMP VARIABLE SPEED 1 * ~~~ * HOT WATER LOOP SUPPLY BRANCH 1 * ~~~ * Components on Branch: * ~~~ * BOILER:HOTWATER:BOILER HOT WATER 1 * ~~~ * HOT WATER LOOP SUPPLY BRANCH 2 * ~~~ * Components on Branch: * ~~~ * PIPE:ADIABATIC:PIPE ADIABATIC 1 * ~~~ * HOT WATER LOOP SUPPLY OUTLET BRANCH * ~~~ * Components on Branch: * ~~~ * PIPE:ADIABATIC:PIPE ADIABATIC 5 * ~~~ * ******* * ~~~ * Possible things to look for to correct this problem are: * ~~~ * Capacity, Operation Scheme, Mass flow problems, Pump Heat building up over time. * ~~~ * Try a shorter runperiod to stop before it fatals and look at * ~~~ * lots of node time series data to see what is going wrong. * ~~~ * If this is happening during Warmup, you can use Output:Diagnostics,ReportDuringWarmup; * ~~~ * This is detected at the loop level, but the typical problems are in the components. * Fatal * CheckForRunawayPlantTemps: Simulation terminated because of run away plant temperatures, too hot