Refrigeration system in EnergyPlus

Hello community,

I'm having trouble understanding how refrigeration systems work, and I'd really appreciate any help I can get to clarify my understanding. Please feel free to correct me if I have any misconceptions.

Thank you.

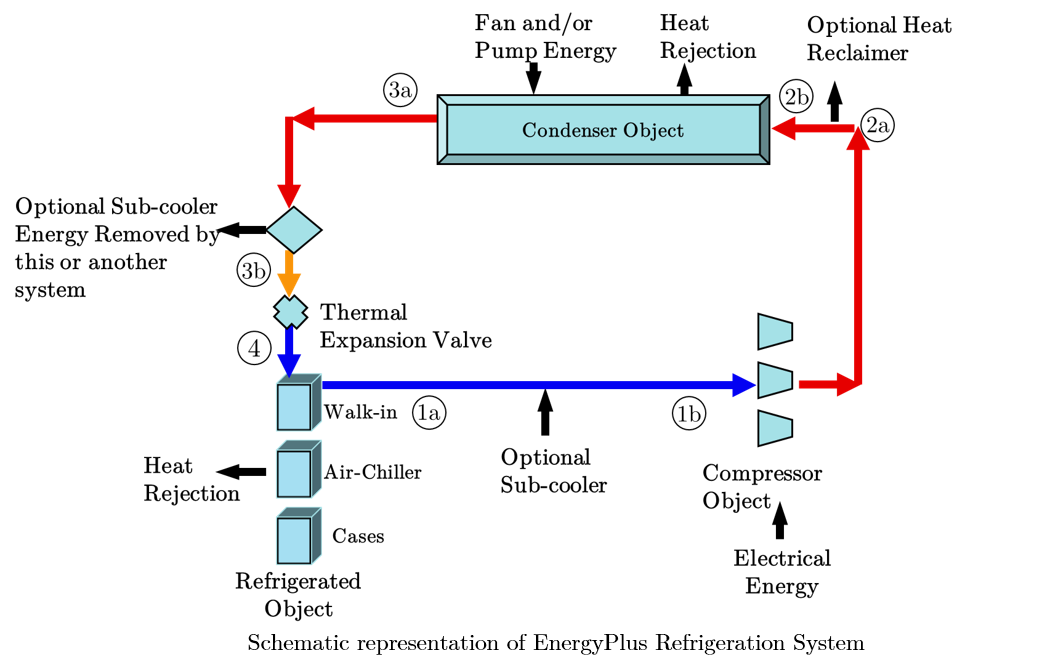

It starts with calculating the internal loads of the refrigerated case using the heat balance model so we know the heat that needs to be rejected.

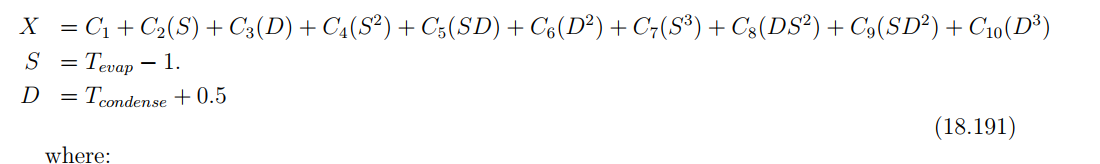

The stat of the refrigerant information is passed to the compressor model and uses the performance curves to calculate the compressor power and the cooling capacity.

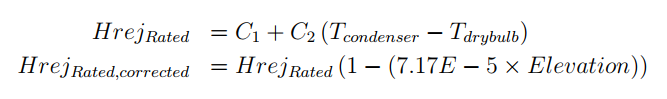

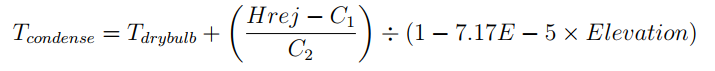

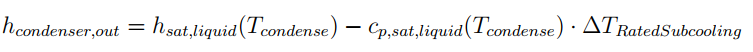

The information on refrigerant state is then used in the condenser model to calculate the condensing temperature and enthalpy of the refrigerant entering the refrigerated case as well as the condenser fan power. The condenser is modeled via the heat rejection performance curve.

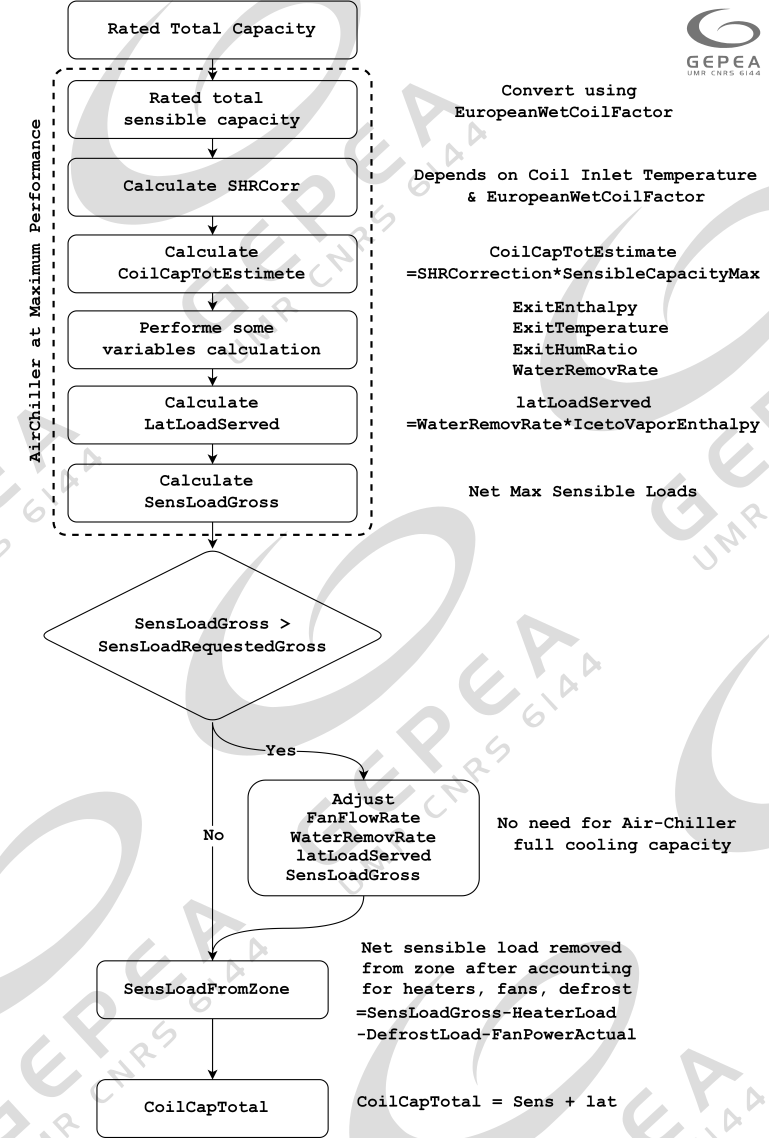

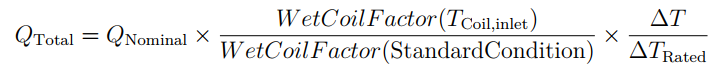

The air inlet temperature and evaporating temperature are used to calculate the actual cooling capacity of the evaporating system (i.e. the air chiller object with European Standard Ratings).

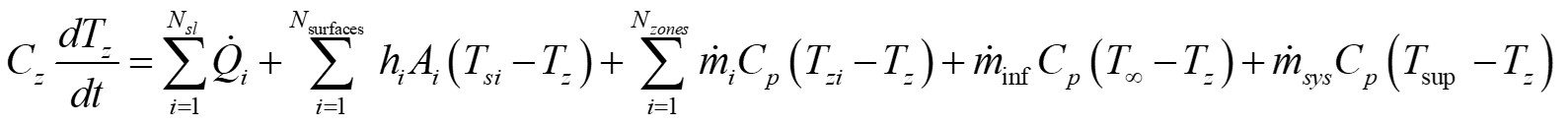

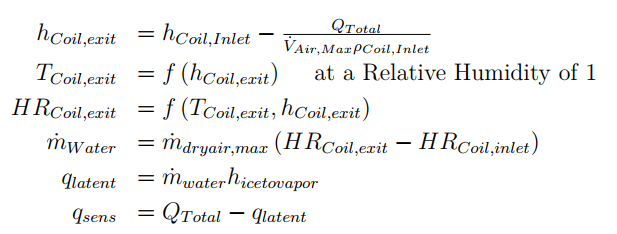

The sensible and latent loads are then calculated as:

Question :

- How the actual reject heat by the condenser is calculated?

- What does E stancd for in the correction factor of the rated heat rejected (1 −7.17E − 5 × Elevation)?

- what is the WetCoilFactor?