Modelling fluid to fluid heat exchanger with more inlet and outlet nodes

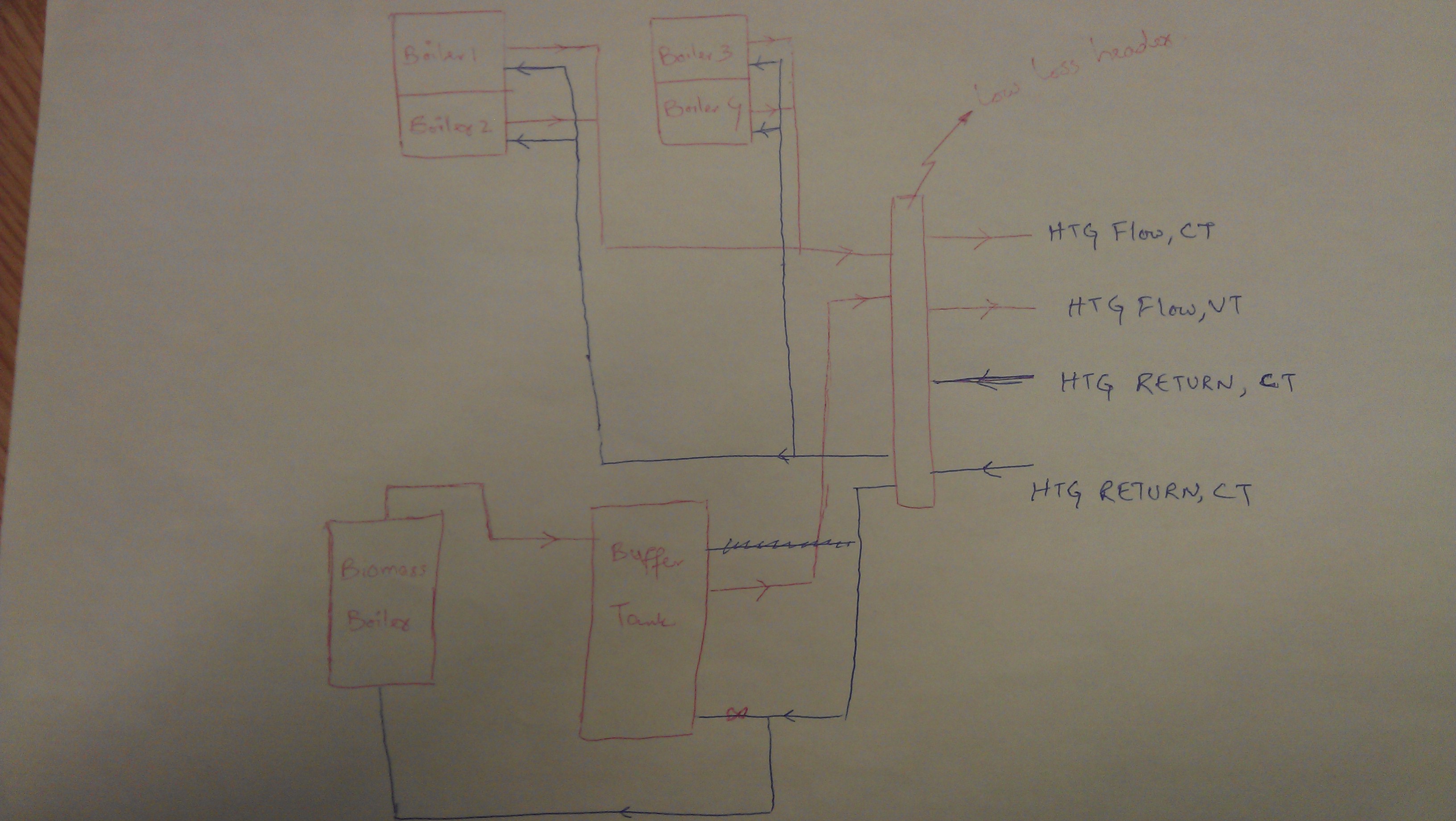

I am modelling an HVAC system that has the below configuration;

one of the boilers (biomass) heats up the buffer tank and the other four boilers (gas boilers) uses a low loss header to heat up the tank. I assume I can model low loss header by using HeatExchanger:FluidToFluid, am I right?

But the problem is I have many input and output nodes (more than I can input in the EnergyPlus HeatExchanger:FluidToFluid object. Any ideas how to model this system in EnergyPlus?

I think the use of splitters/mixers won't help, because the low loss headers has output nodes for variable temperature circuit (i.e. serving radiant panels), constant temperature circuit (services hot water to AHUs, underfloor heating) and connections going back to buffer vessels. Any ideas on this?

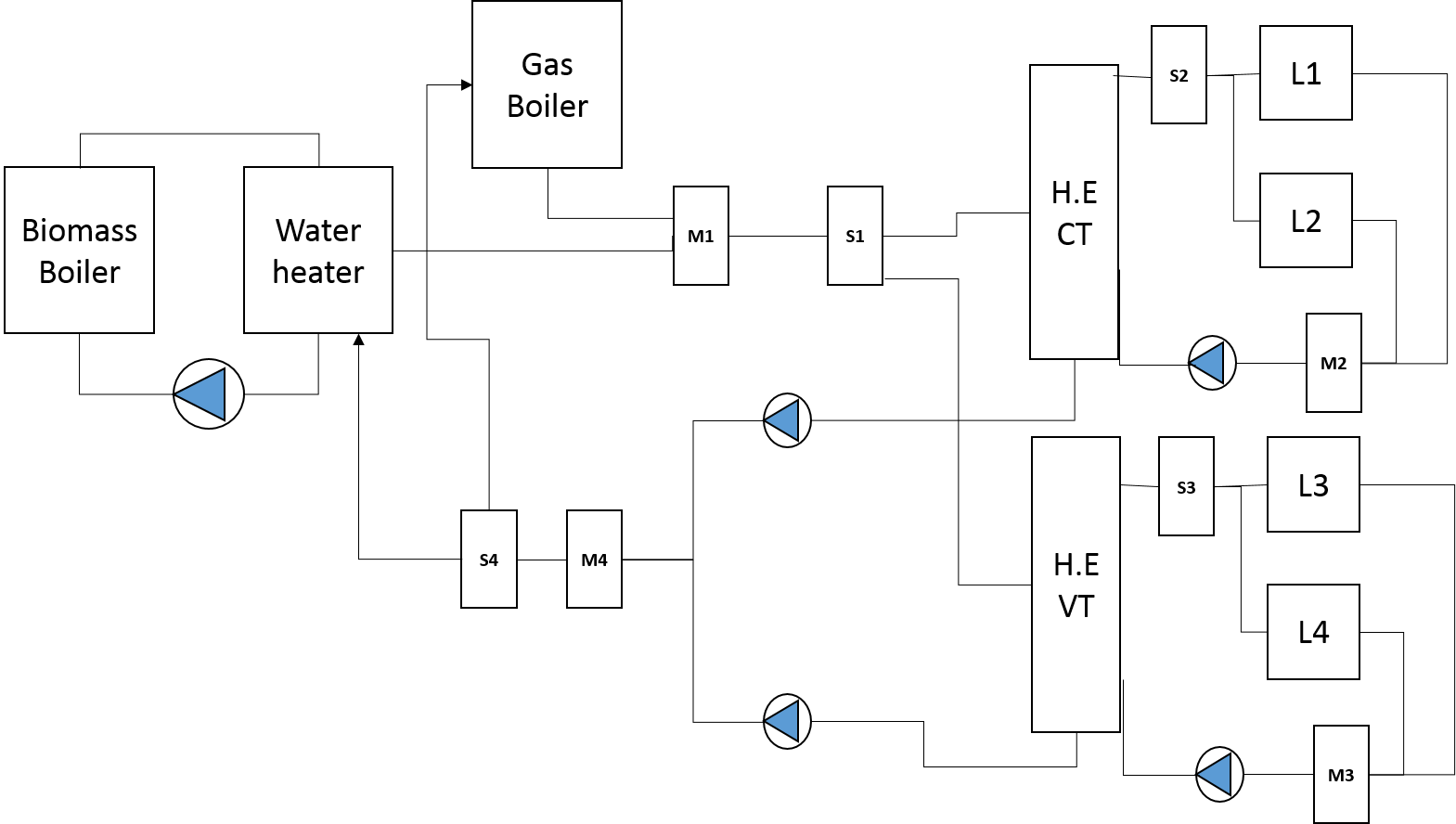

Also, how once can model variable temperature and constant temperature circuits? Do I have to use set-point managers or something else? Or we can simplify the HVAC system for modelling purposes? I have added a second picture to show EnergyPlus loops.

@Waseem I removed some of your tags that were very specific and not likely to be used.

Thanks @MatthewSteen

@Waseem: I'm curious what you program you used to draw the computer schematic?

@Julien Marrec: I think it was Microsoft Powerpoint.