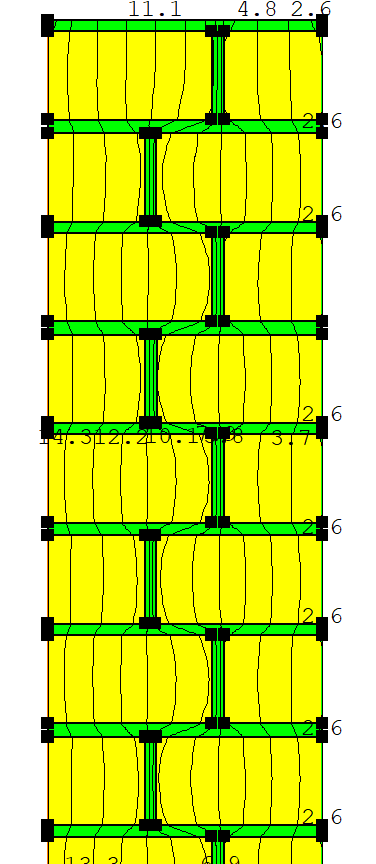

Just to be clear, the "green" slivers are mortar, bonding "yellow" stone (as illustrated in the cross section)? And individual stones are always staggered; no single stone ends up linking indoor to outdoor environments? I would first spend some time evaluating just how sensitive steady-state U-factor estimations are to various cross-section configurations, e.g.

- 1x (volume-weighted) homogeneous material

- the above cross-section layout

- a finer bonding pattern (some stones in the photo appear quite small)

In the end, it may not be worth the effort. But at least you would get a sense of the range of possible outcomes (i.e. average assembly conductivity). Here's a link to a nice BRE study on guarded hot-box investigations of solid masonry assemblies. Aspects like bonding configurations, mortar moisture content and air gaps in the assemblies are considered. Interesting read!

What is the ultimate purpose of estimating steady-state U factors? Inputs for annual energy simulations? If so, I'd spend as much time identifying other attributes of the assembly (e.g. mass/density of the assembly), in addition to air-tightness & thermal bridging at various interfaces (e.g. around doors/windows). These would be as important (if not more) than a steady-state U factor IMHO (depending on the context, e.g. site, end-use), yet are generally hard to come by. If the assembly is expected to be exposed to frequent cycles of precipitation, solar-driven moisture penetration (mortar), drying, etc., then maybe combined heat and moisture modelling might be more suitable. An EnergyPlus link, but many packages offer similar functionality (e.g. WUFI+, TRNSYS, ESP-r).