How to set LoadProfile:Plant on DesignDay

(This post is slightly related to my previous post about SwimmingPool:Indoor.)

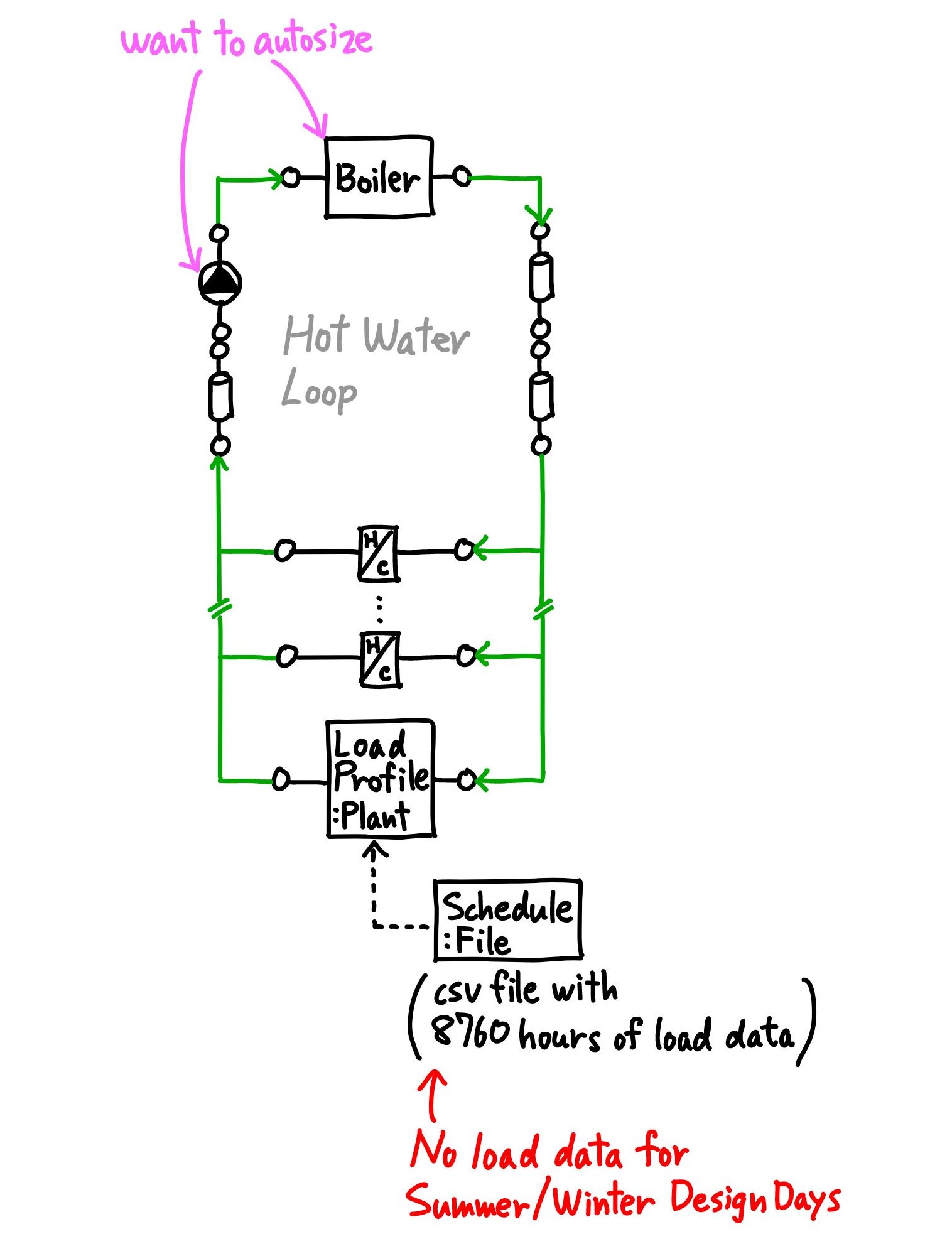

I want to use LoadProfile:Plant in conjection with many Coil:Heating:Water objects in a hot water plant loop as shown below.

I already know 8760 hours of load profile for LoadProfile:Plant, but the entire load in the hot water loop is unknon. So, I want to simulate sizing run and autosize the boiler, pump and heating coils.

LoadProfile:Plant is used with ScheduleFile. I also know the load profile for LoadProfile:Plant on WinterDesignDay and SummerDesignDay. However, the load profile on DesignDays cannot be input to ScheduleFile. How can I set set load of LoadProfile:Plant on DesignDays?

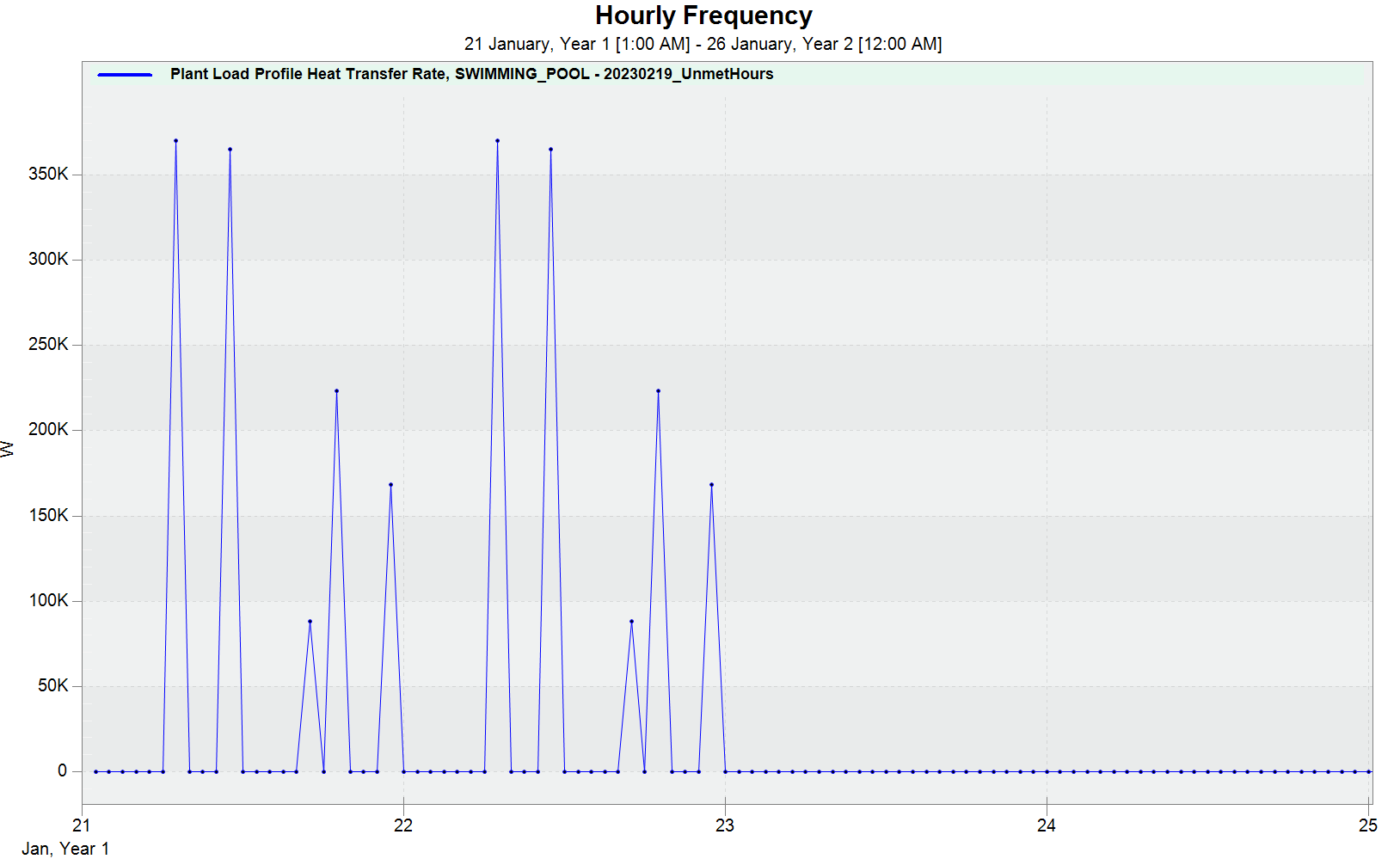

According to Application Guide for EMS, it seems that "CurrentEnvironment == 1" represents WinterDesignDay when WinterDesignDay is Obj1 of SizingPeriod:DesignDay. I tried to override ScheduleFile during the sizing run with EMS, but my EMS input does not work for now. During the sizing run, EnergyPlus refers to loads on the same date as the sizing day in ScheduleFile i.e. load on January 21st for WinterDesignDay in my case, which is not what I expect.

I would appreciate it if anyone could correct my EMS input below or advise any other way to set LoadProfile:Plant on DesignDays.

! CHICAGO_IL_USA Annual Heating 99% Design Conditions DB, MaxDB= -17.3°C

SizingPeriod:DesignDay,

CHICAGO_IL_USA Annual Heating 99% Design Conditions DB, !- Name

1, !- Month

21, !- Day of Month

WinterDesignDay, !- Day Type

-17.3, !- Maximum Dry-Bulb Temperature {C}

0.0, !- Daily Dry-Bulb Temperature Range {deltaC}

, !- Dry-Bulb Temperature Range Modifier Type

, !- Dry-Bulb Temperature Range Modifier Day Schedule Name

Wetbulb, !- Humidity Condition Type

-17.3, !- Wetbulb or DewPoint at Maximum Dry-Bulb {C}

, !- Humidity Condition Day Schedule Name

, !- Humidity Ratio at Maximum Dry-Bulb {kgWater/kgDryAir}

, !- Enthalpy at Maximum Dry-Bulb {J/kg}

, !- Daily Wet-Bulb Temperature Range {deltaC}

99063., !- Barometric Pressure {Pa}

4.9, !- Wind Speed {m/s}

270, !- Wind Direction {deg}

No, !- Rain Indicator

No, !- Snow Indicator

No, !- Daylight Saving Time Indicator

ASHRAEClearSky, !- Solar Model Indicator

, !- Beam Solar Day Schedule Name

, !- Diffuse Solar Day Schedule Name

, !- ASHRAE Clear Sky Optical Depth for Beam Irradiance (taub) {dimensionless}

, !- ASHRAE Clear Sky Optical Depth for Diffuse Irradiance (taud) {dimensionless}

0.0; !- Sky Clearness

Schedule:File,

Swimming_Pool_Load_Schedule, !- Name

, !- Schedule Type Limits Name

C:\Project\Swimming_Pool_Load_Schedule\Swimming_Pool_Load_Schedule.csv, !- File Name

2, !- Column Number

1, !- Rows to Skip at Top

8760, !- Number of Hours of Data

Comma, !- Column Separator

No, !- Interpolate to Timestep

60, !- Minutes per Item

No; !- Adjust Schedule for Daylight Savings

LoadProfile:Plant,

Swimming_Pool, !- Name

Swimming_Pool Inlet, !- Inlet Node Name

Swimming_Pool Outlet, !- Outlet Node Name

Swimming_Pool_Load_Schedule, !- Load Schedule Name

0.0398, !- Peak Flow Rate {m3/s}

ASHRAE90.1_Schedule_H_Ventilation; !- Flow Rate Fraction Schedule Name

!- =========== ALL OBJECTS IN CLASS: ENERGYMANAGEMENTSYSTEM:ACTUATOR ===========

EnergyManagementSystem:Actuator,

Swimming_Pool_Load_Schedule_Override, !- Name

Swimming_Pool_Load_Schedule, !- Actuated Component Unique Name

Schedule:File, !- Actuated Component Type

Schedule Value; !- Actuated Component Control Type

!- =========== ALL OBJECTS IN CLASS: ENERGYMANAGEMENTSYSTEM:PROGRAMCALLINGMANAGER ===========

EnergyManagementSystem:ProgramCallingManager,

EMS_PCM_Pool_Load_Schedule_Override, !- Name

AfterComponentInputReadIn, !- EnergyPlus Model Calling Point

EMS_Program_Pool_Load_Schedule_Override; !- Program Name 1

!- =========== ALL OBJECTS IN CLASS: ENERGYMANAGEMENTSYSTEM:PROGRAM ===========

EnergyManagementSystem:Program,

EMS_Program_Pool_Load_Schedule_Override, !- Name

IF ...