Inconsistency in curve calculations

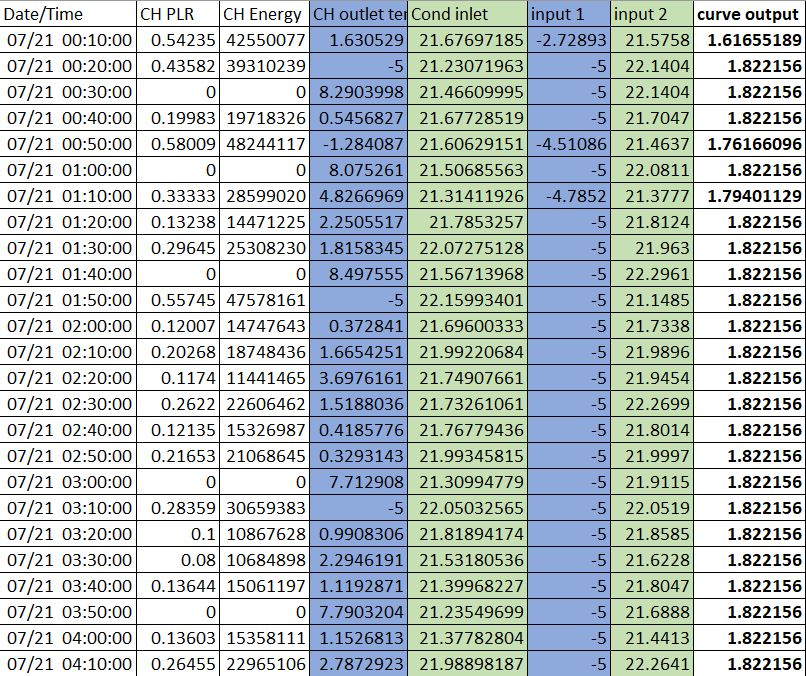

I found a problem with the curve input/output in my model. The curve is used for chiller performance (EirFTemp). I have reported the following variables:

Output:Variable,Water Cooled Chiller EItoCoolingOutputRatioFofT,Performance Curve Input Variable 1 Value,timestep; !- HVAC Average []

Output:Variable,Water Cooled Chiller EItoCoolingOutputRatioFofT,Performance Curve Input Variable 2 Value,timestep; !- HVAC Average []

Output:Variable,Water Cooled Chiller EItoCoolingOutputRatioFofT,Performance Curve Output Value,timestep; !- HVAC Average []

(since I'm using Chiller:Electric:EIR object, variable 1 is chiller outlet temperature and variable 2 is chiller's condenser inlet temperature)

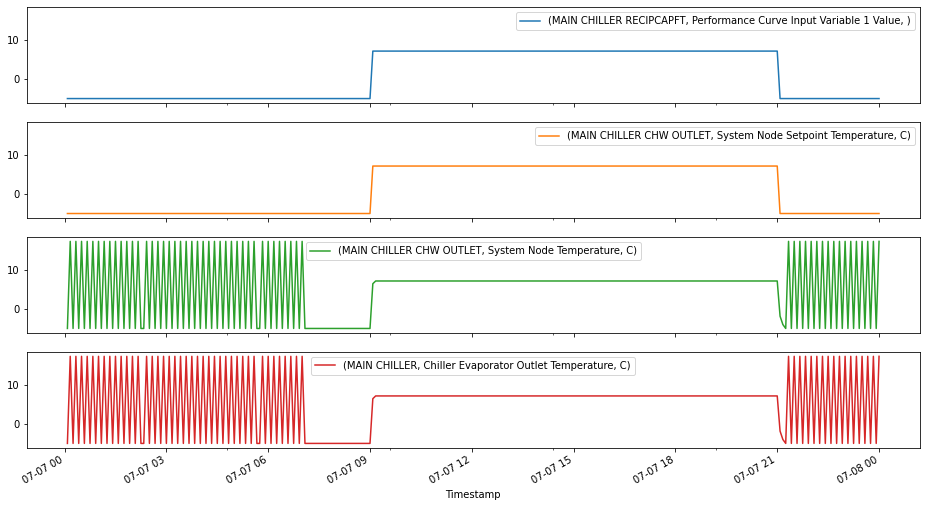

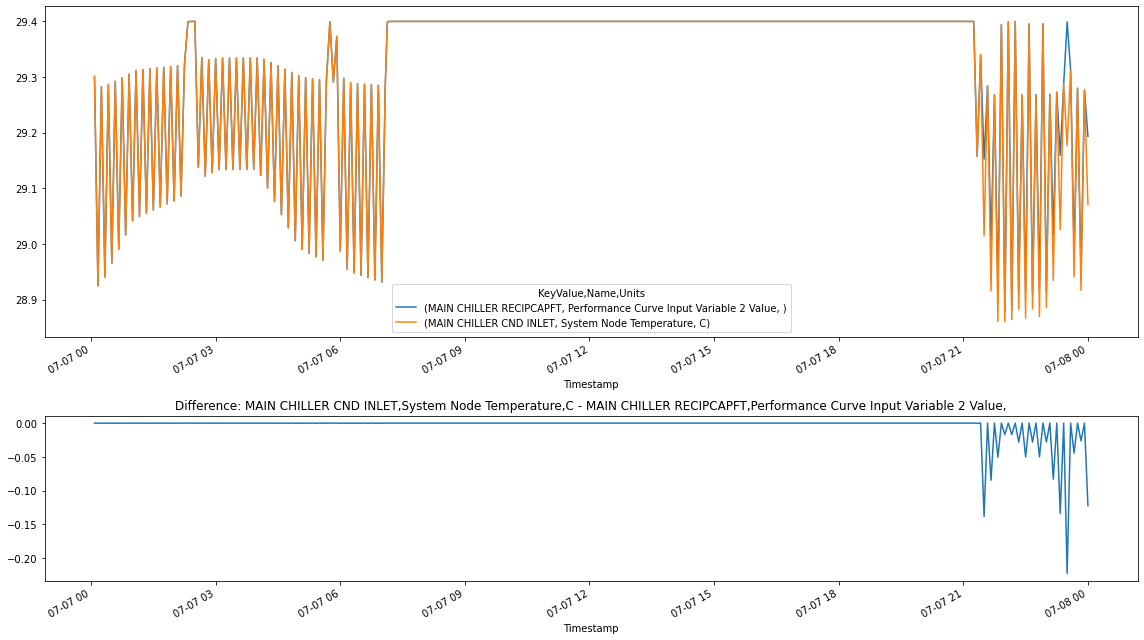

I need to modify the curve output by EMS, so I decided to use sensor variables (chiller outlet temperature & condenser inlet temperature). As you can see in below, I realized the curve is using input variables much different from sensor variables that I'm receiving from energyplus:

Columns with same color should have a same value (at least with a time lag!). But they are much different specially for the chiller outlet temperature. Why the input 1 of the curve is different from chiller outlet temperature?! Where does it come from?!

Update: I should mention that it happens mostly when the chiller outlet temperature setpoint is negative (e.g. -5).

Update (following my response to Julien): I think I narrowed down the problem. The IceStorage-Series-ChillerUpstream.idf example file works fine because there is no night time load on the secondary side of the loop. I changed the night time setpoint. So chiller should charge (with -5 setpoint) & also provide cooling for the secondary loop (with a 6.7 setpoint). Also, the ice storage outlet has a 6.7 C setpoint all the time. Since there are a two-way common pipe and separate pumpings on the primary and secondary side, having both charging and cooling can't be a problem! Here is files where I compared EnergyPlus example with modified one with nightload.

Could you share your file or better yet, a minimum complete verifiable example (MCVE) (for eg taking one of the energyplus ExampleFiles as a starting point) please? I'd like to be able to reproduce the issue locally to see what's going on.

@Julien Marrec,

IceStorage-Series-ChillerUpstream.idfis kinda similar to my case, but there is one big issue with this idf! chiller curves have an evaporator limit of 5 while it produces -5 for ice making. I used the curves that I had in my model and the output was FINE! First I don't know why the chiller output temperature is not equal to setpoint (-5) sometimes that PLR is non-zero! Second I don't know why the input for the curves is different from the sensor value!