How to configure parallel branch pumps for fan coils in a chiller system

Hello everyone,

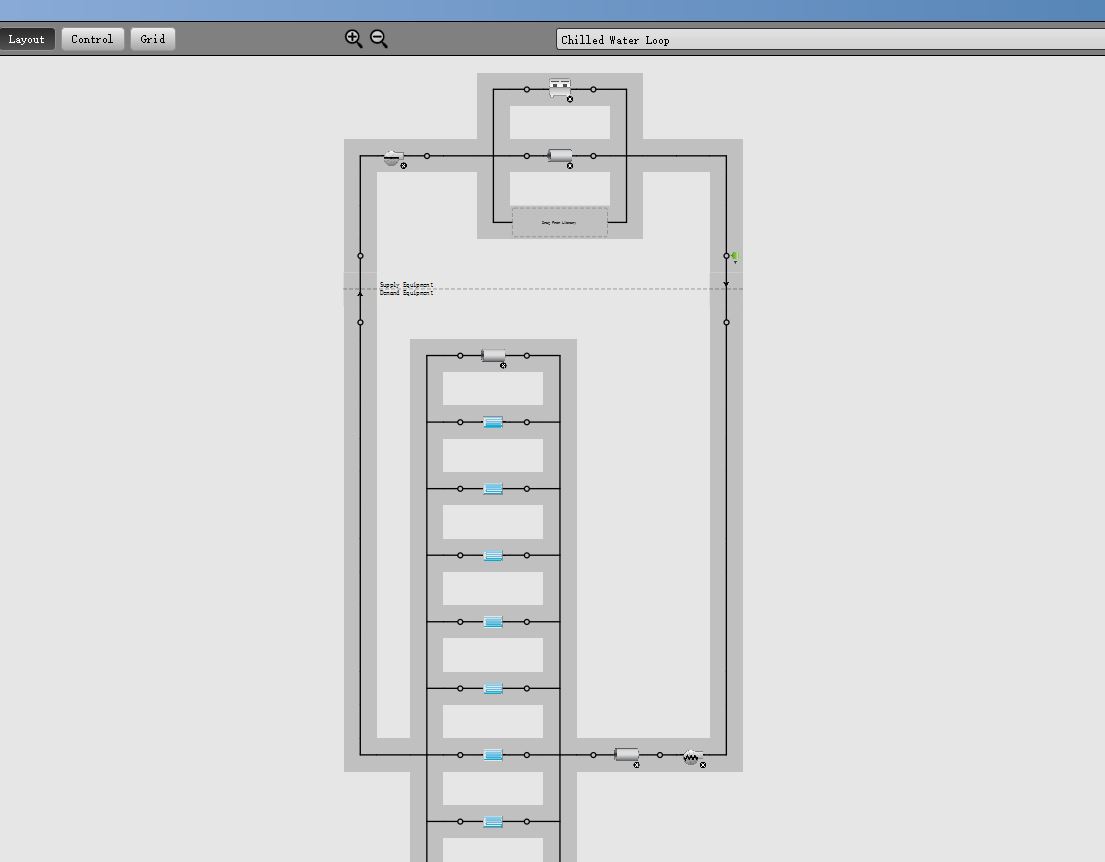

I just developed a primary-secondary chilled water system to provided the chilled water for multiple ZoneHVAC:FourPipeFanCoil that are served as Zone Equipmentsin thermal zones. The current configuration of the system is like the figure as below and i also attach my osm file here for you guys to download https://drive.google.com/file/d/1bjju... :

.

.

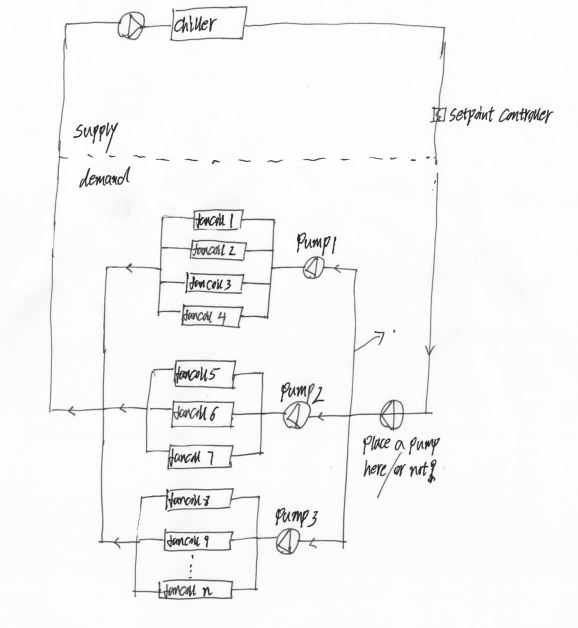

My question is how to configure my system according to the following figure.

I want to use three pumps to serve the ZoneHVAC:FourPipeFanCoil that are distributed in different parts of a building. For example, the fan coils in 1st-3rd floors will be served by pump 1, and fan coils in 4th-7th floors will be served by pump 2 and fan coils in other floors will be served by pump 3. This configuration is very common in real engineering project, but i did not find a way to add a parallel branch for the fan coils and pumps. I read the Engineering Reference of Energyplus and it seems that only one splitter and mixer is allowed for the supply or demand half loop.

Is anyone has an idea on how to handle this issue. Thank you Very much!