Chiller Plant Model

Hello,

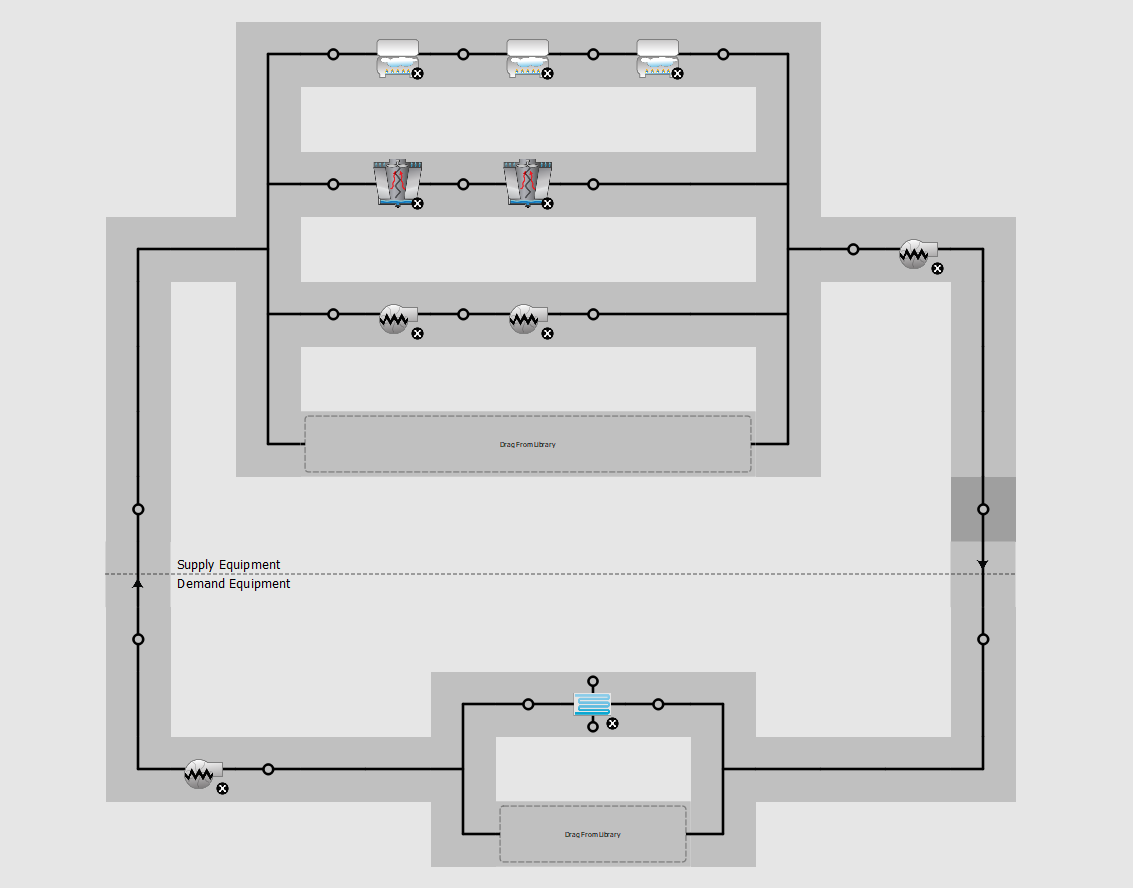

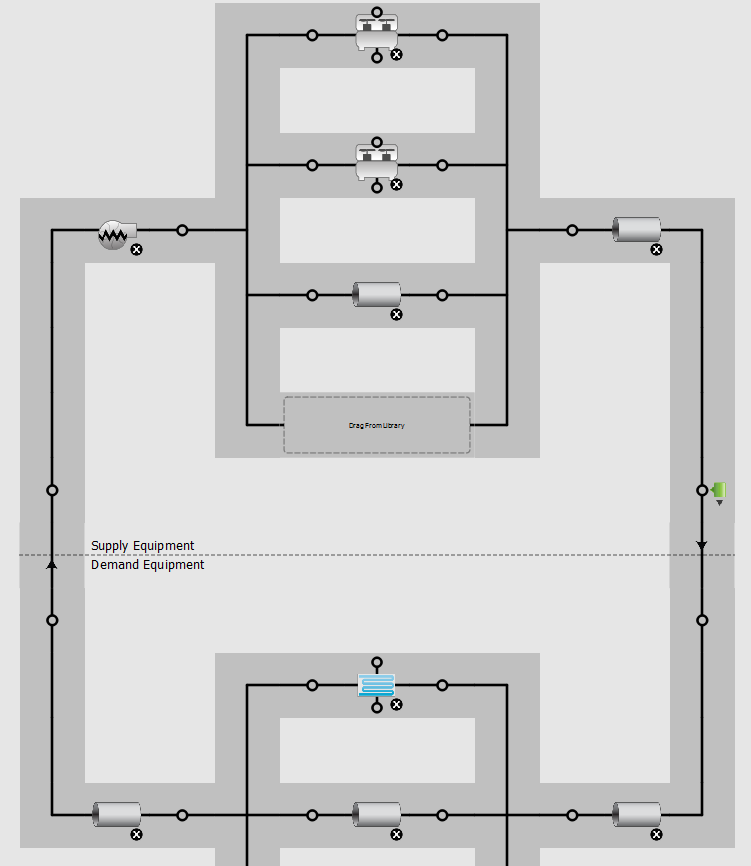

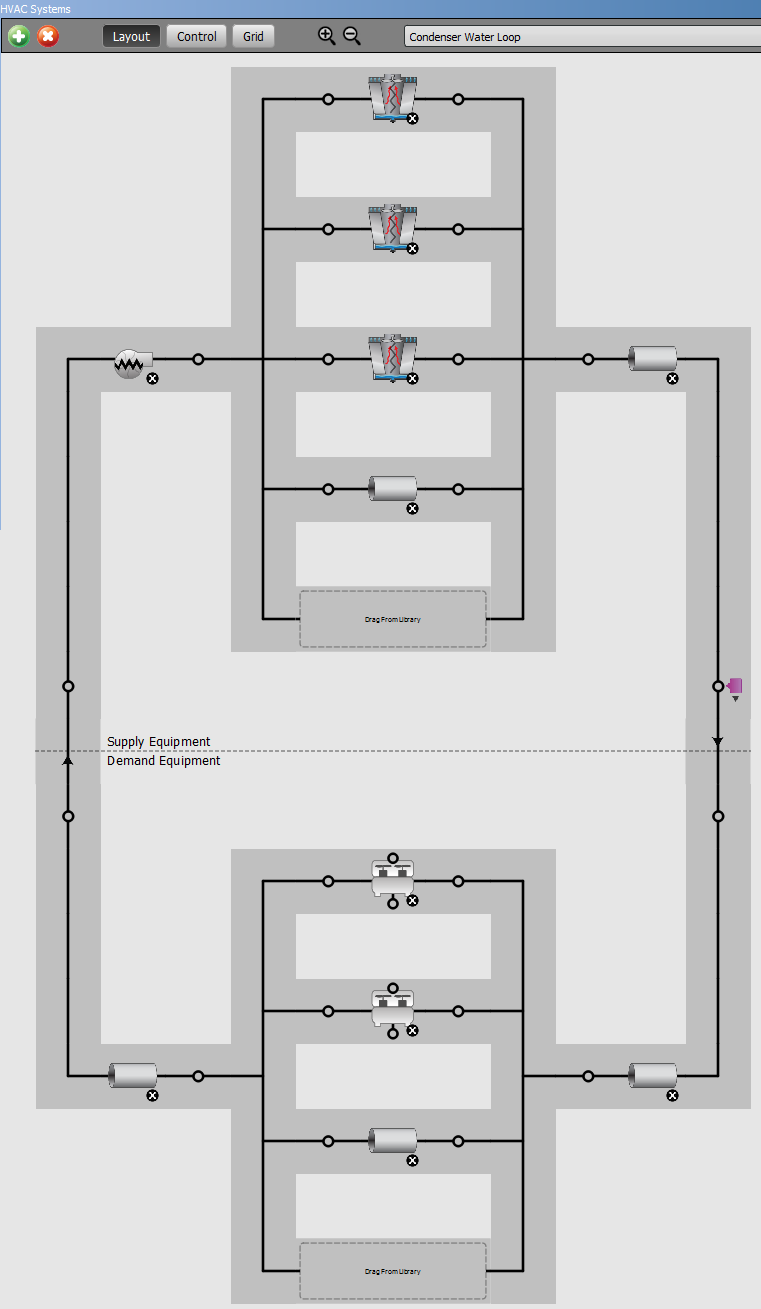

I'm trying to model a chiller plant (two cooling towers, three chillers ((staged)) and multiple pumps) that serves multiple buildings. I am doing a trial run for one building, but am having trouble coming up with the best way to tackle modeling the system. I am using SketchUp/openstudio.

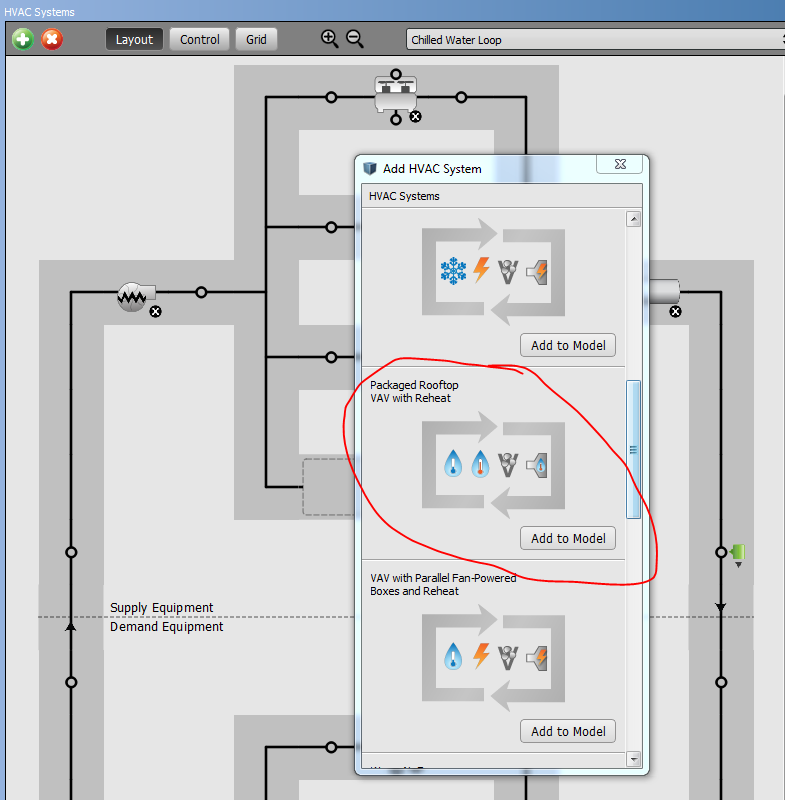

My first instinct was to build the plant, which I will replicate into a model for each building, then attach the "demand side" system on a building and zone level. Is this the best way to go about this type of model? if so I am a little confused as to what components (besides those mentioned above) are mandatory for the model to run? I am also a confused as to which node to place the components on. example: should all three chillers go on the same line on nodes that are horizontal to one another or on separate lines that are vertical from one another?

What software are you using? Please edit the question to include this.

I am using SketchUp/ Openstudio. I have made the edit to the question. Thanks!