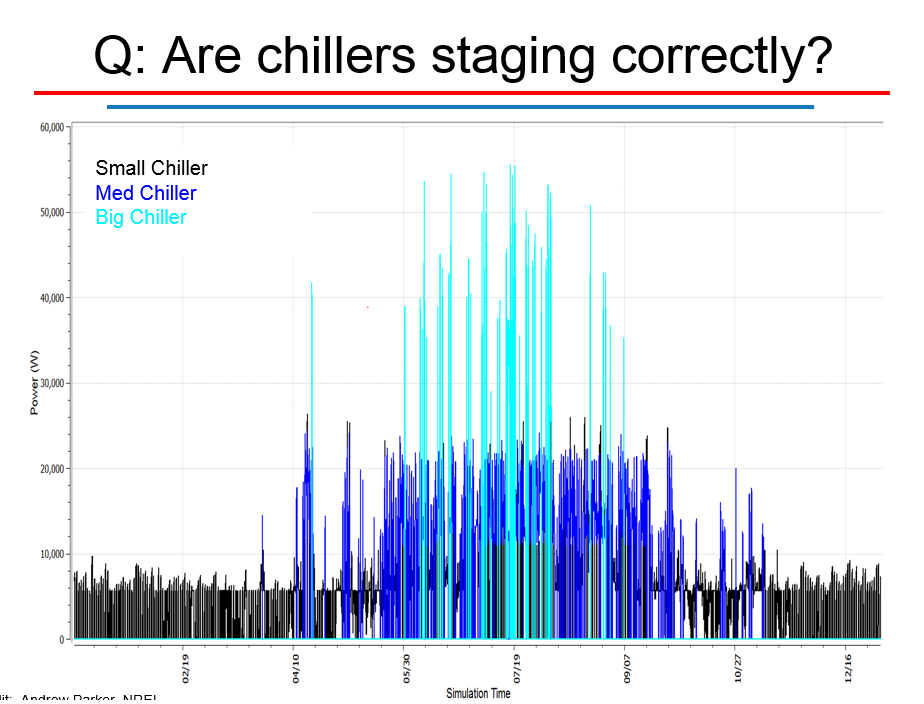

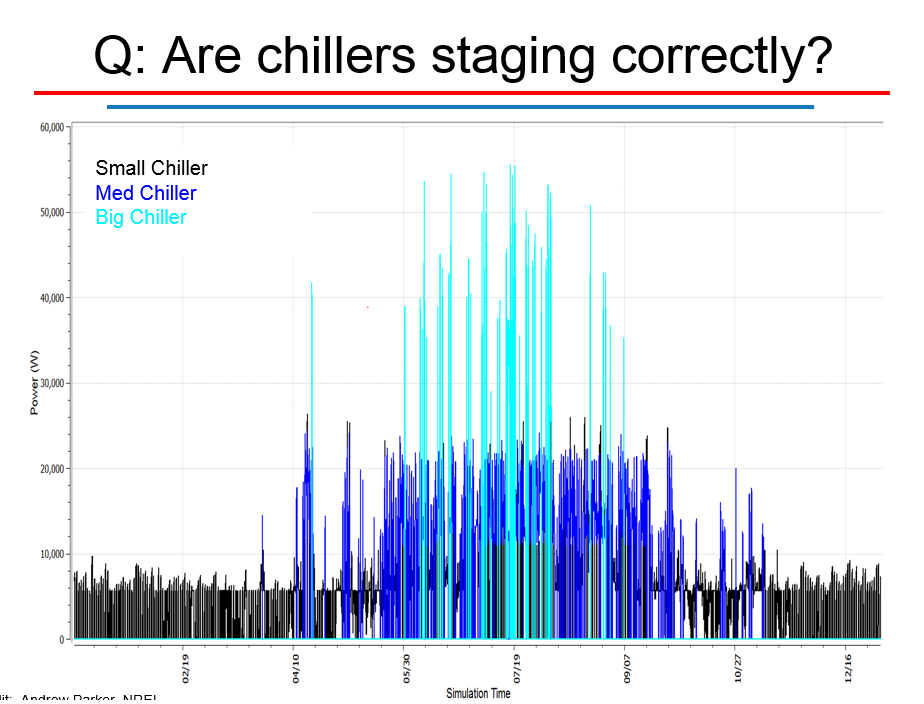

@TomB is right, and the chart he suggested should be your starting point:

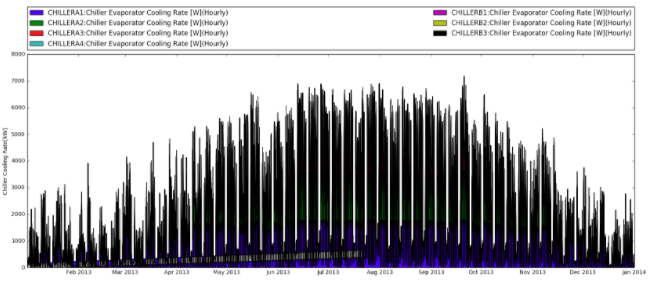

- Report the timeseries cooling output for every chiller

- Graph them all on the same plot

It will probably look something like this:

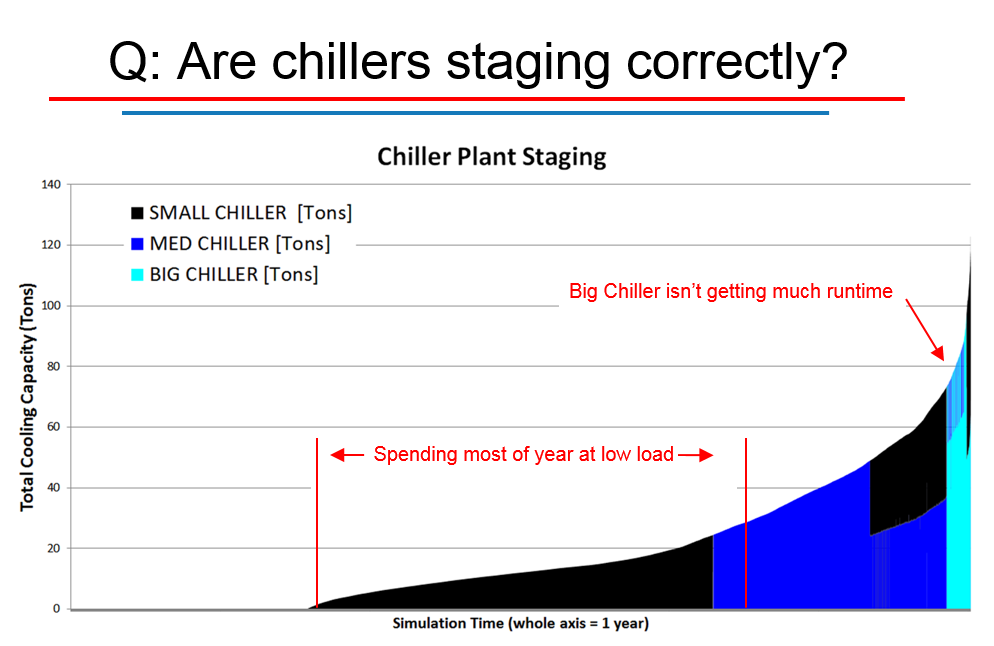

Graphed this way, I find it challenging to see if the overall staging scheme is working correctly without a lot of zooming in on the details of each day unless the staging scheme is very simple. Instead, I like to use those same outputs to create a different graph to understand how the chillers (or boilers, or other plant equipment) are staging:

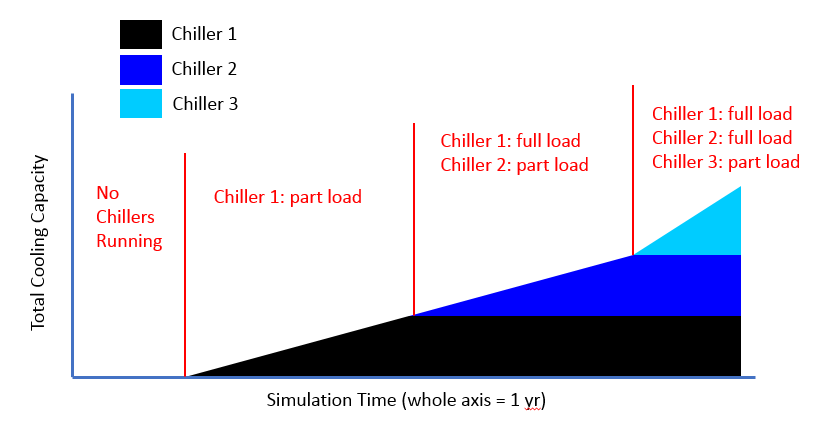

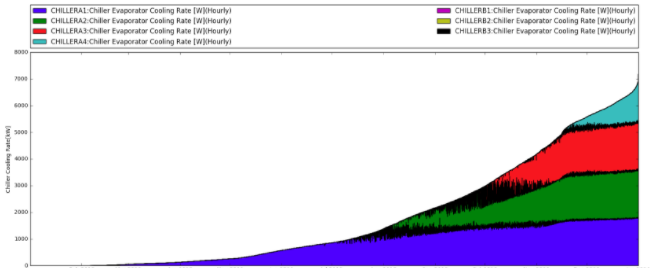

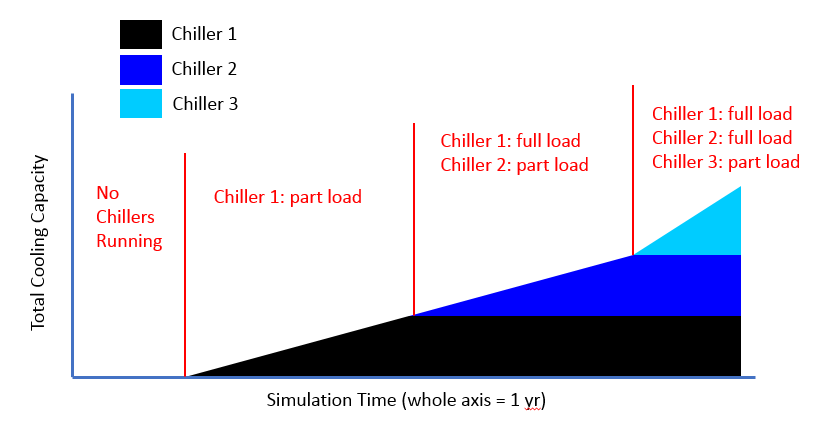

- Sum up the cooling output for each chiller

- Sort the timeseries from smallest to largest total cooling output

- Plot a stacked timeseries of the sorted results.

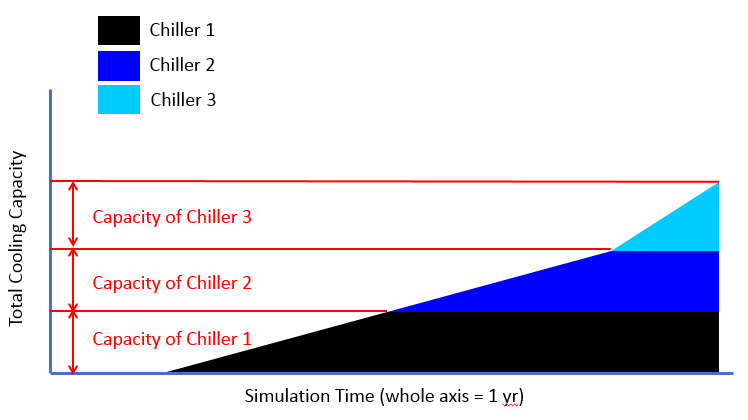

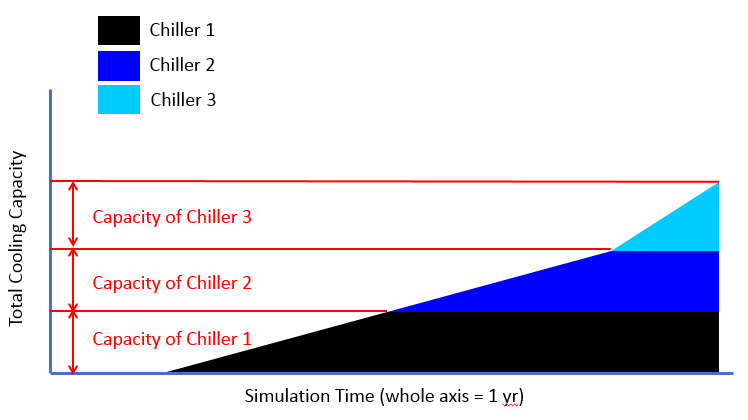

Three chillers running sequentially should look like the image below.

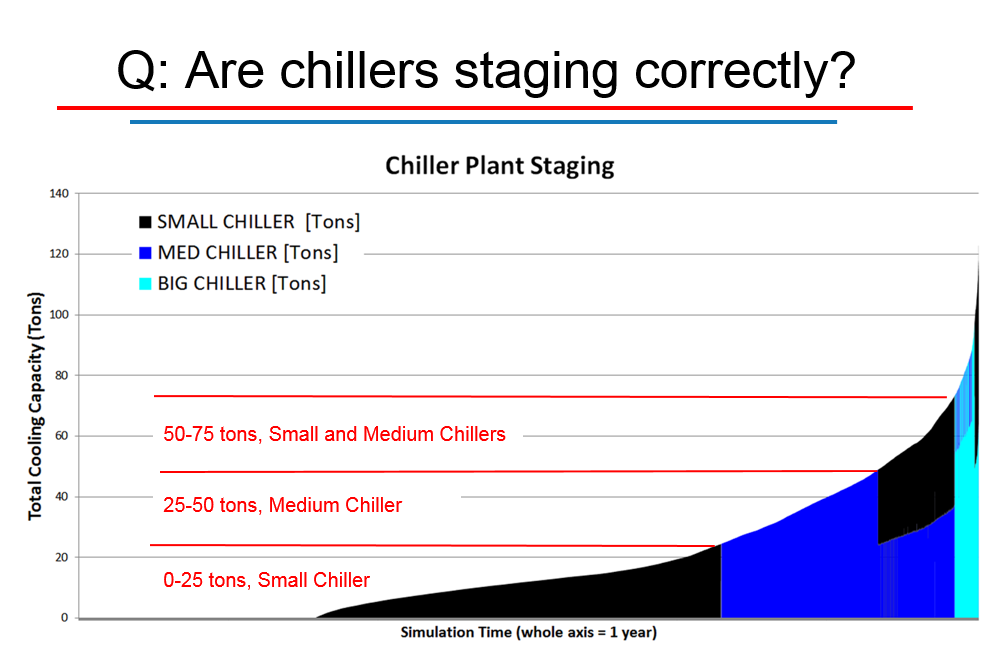

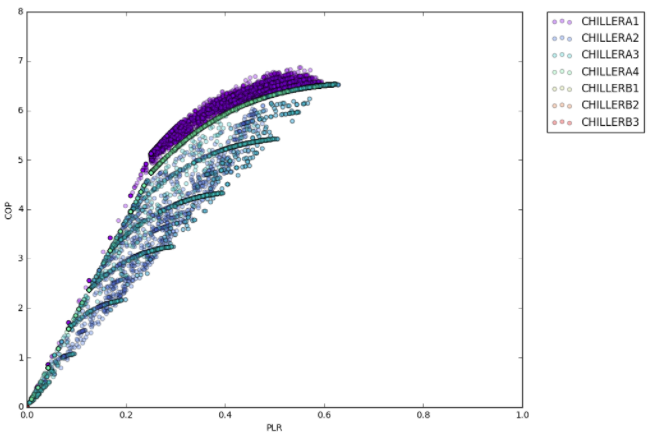

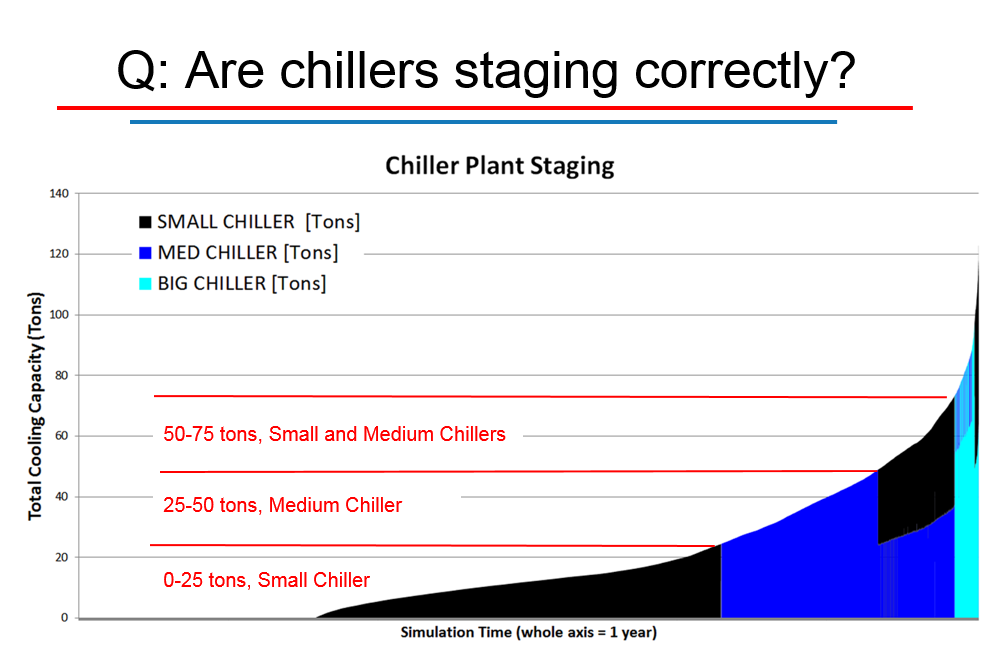

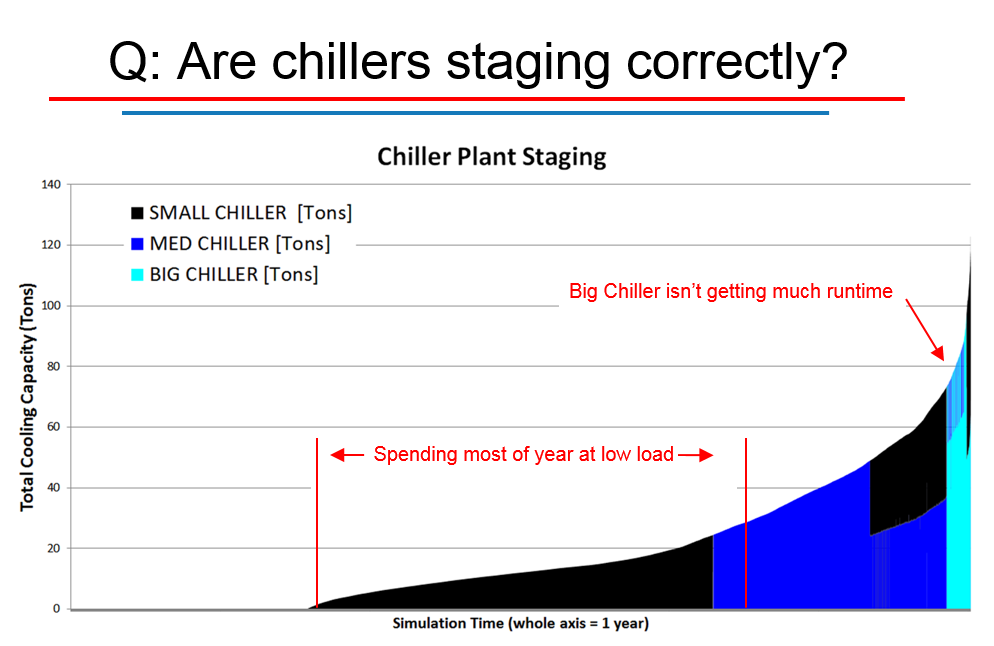

The graph below shows actual simulation output for a more complex staging scheme. There are 3 chillers and 4 different capacity ranges. Only certain chillers are used inside each capacity range, and within each range, the chillers stage 'optimally'. As you can see, this chart makes it very easy to confirm that the model is working as intended.

A nice bonus of this graph is that you can easily see how much of the year is spent in each operating range.

UPDATE:

First, a clarification: images 2 and 3 are just drawings in powerpoint, not actual simulation data. Images 1, 4, and 5 are actual simulation data.

Second, here are the key objects/inputs for getting staging right:

Chiller:Electric:EIR Sizing Factor. The sizing factor field controls the sizing of each piece of equipment on the plant loop, and the default is 1 (100%). If you have 3 chillers, all with a sizing factor of 1, then each chiller will be sized to meet 100% of the load of the plant loop. This means you'll end up with 300% of the required capacity, and only 1 chiller will ever run. If you want to get 3 equally sized chillers, which, combined, would meet the total cooling load, you would set the sizing factor to 0.33 in each chiller. Also, the sizes don't have to be equal, you could have a 0.2, a 0.3, and a 0.5 or some other combination.

PlantEquipmentOperation:CoolingLoad. This object determines which pieces of equipment are allowed to operate for a given range of capacities. By default, there is only 1 range (0+ W), and every piece of equipment is allowed to operate. The 4th image in this post shows the results of a more detailed staging scheme:

- 0-25 tons: Small Chiller

- 25-50 tons: Medium Chiller

- 50-75 tons: Small Chiller, Medium Chiller

- 75-100 tons: Medium Chiller, Big Chiller

- 100+ tons: Small Chiller, Big Chiller

It is important to understand that allowed to operate just means that the equipment may be used, not that it will be used. Determining which pieces of equipment do operate is the role of the next field:

PlantLoop Load Distribution Scheme. This ...

(more)

It generally seems to be working as intended; not sure if the black in the graph is ChillerB3 or if it the top of each series has a black border. Also, I forgot to mention you should be using "Detailed" as the output frequency. The HVAC systems operate on a sub-hourly basis, so if you use "Hourly" you can see some confusing fluctuations which are just the effects of the hourly averaging.

@aparker Thank you for your comment. Do you know how I can interpret the fact that each chiller doesn't operate to maximum part load ratio(100%) even though I specify

Sequential LoadforChilled Water Distribution Scheme?