Energyplus: is it possible to increase the variability of power demanded for a chilled water plant?

Hi everyone!

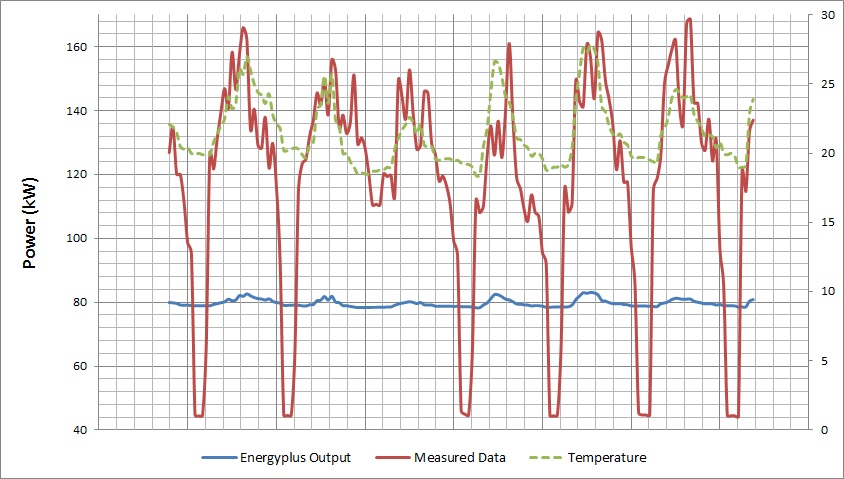

I have this Energyplus model which simulate a hospital building energy consumption. The building has 3 air-cooled chillers with a total capacity of 220 TR which deliver only cooled air. The system has 27 fancoils and 4 pumps without modulation. Comparing the real and simulated plant shows a big deviation: to illustrate, I plotted the measured data and Energyplus output (time axis over X) for a little period (temperure of outdoor air included).

As you might remark, the measured data has a great variability! To put in numbers, the standard deviation for measured data is about 34 kW (whole measurement period), while the simulation stands for 5 kW (almost seven times lower).

I am wondering which setting I can change in my model in order to increase the power demand variability for the chilled water plant. Some attempts that I already tried without success:

- Change Chiller COP; - Change Chiller Flow Mode from NotModulated to LeavingSetpointModulated; - Change constant speed pump to variable speed; - Change constant volume to variable volume.

Someone can help me in this issue?