This is an outstanding question we have run into time & again. Especially since 90.1 does not address.

AN approach we have take is to work with a rep to get minimally compliant Screw and Centrifugal curves and generate 'custom' curves using an in-house tool. A major issue, as @Jim Dirkes, alluded to is that the EER and IEER and contradictory goals in some/many/all cases. Finding chillers that even come close to both values has been...challenging. So for example; 'savings' are left on the table when a chiller with a better IEER is picked b/c is the 'worst' performing chiller EER.

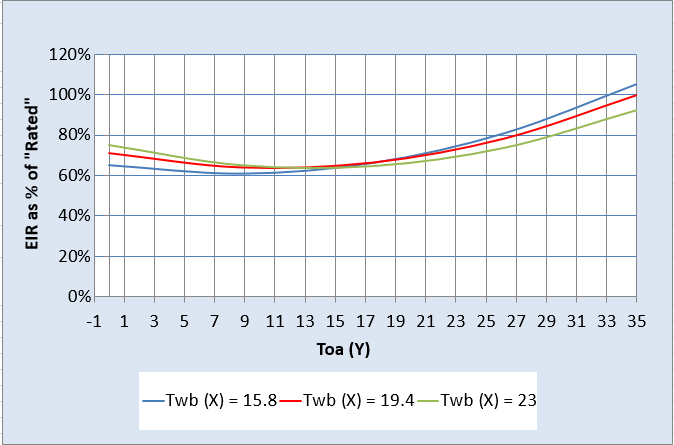

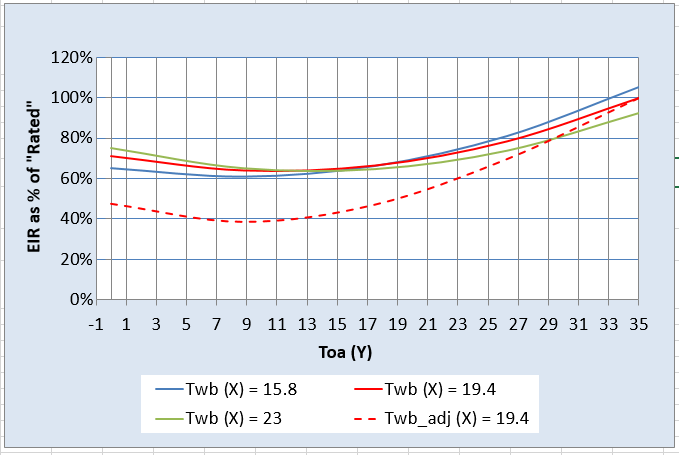

This approach was initially taken because we found the 'default' curves that come in eQuest to be unrealistic when compared to actual selections. An example would be the performance of the a Centrifugal chiller true at low Part Load Ratio (PLR) load conditions. The EIR/PLR ratio for a the default shows a drastic drop-off at part-load, whereas a 'real' chiller will not exhibit this behavior. Translation: The default chiller unloads unrealistically good; placing the Proposed/comparison at a significant disadvantage at part load.

Note: I thought the eQuest curves (mostly?) align with COMnet chiller curves; though my quick spot checks are leaving me second guessing...... It is also not clear from my (quick) re-review of COMnet, and I don't recall, seeing a source for these curves sited in the text. I personally find these curves hard to believe - both COMnet and eQuest- , but I also like data. (Engineer here). A key discrepancy is the use of a single quadratic for EIR-FPLR in COMcheck vs a Bi-quadratic in eQuest. Though, both aren't terribly 'believable' when we've compared them to actual chiller selections. I'd love to hear/review any sources anyone can share or point to.

I have asked the question as to why ASHRAE does not supply/specify this information. The answer I have gotten has been something along the lines of "...its not ASHRAE's position to specify equipment curves - its up to AHRI/ARI since its their domain to rate equipment...."...I'm paraphrasing, but same idea. These leave modelers in many cases in an odd spot. I don't think it is unreasonable to have a standard set of curves which define the performance of a Baseline piece of equipment. Maybe there's a committee for that, unknown.

This is an area that is lack solid guidance on and would also like to hear others' take on the approach; even if it is 'default and run'.

FWIW, this is something that I haven't dealt with in the OpenStudio baseline automation code, and that PNNL has not dealt with in the DOE Prototype Buildings. In both cases, we use "typical" curves and then modify the COP. If anyone has a good idea for a scheme to do this repeatably I can code it up and see how it works.