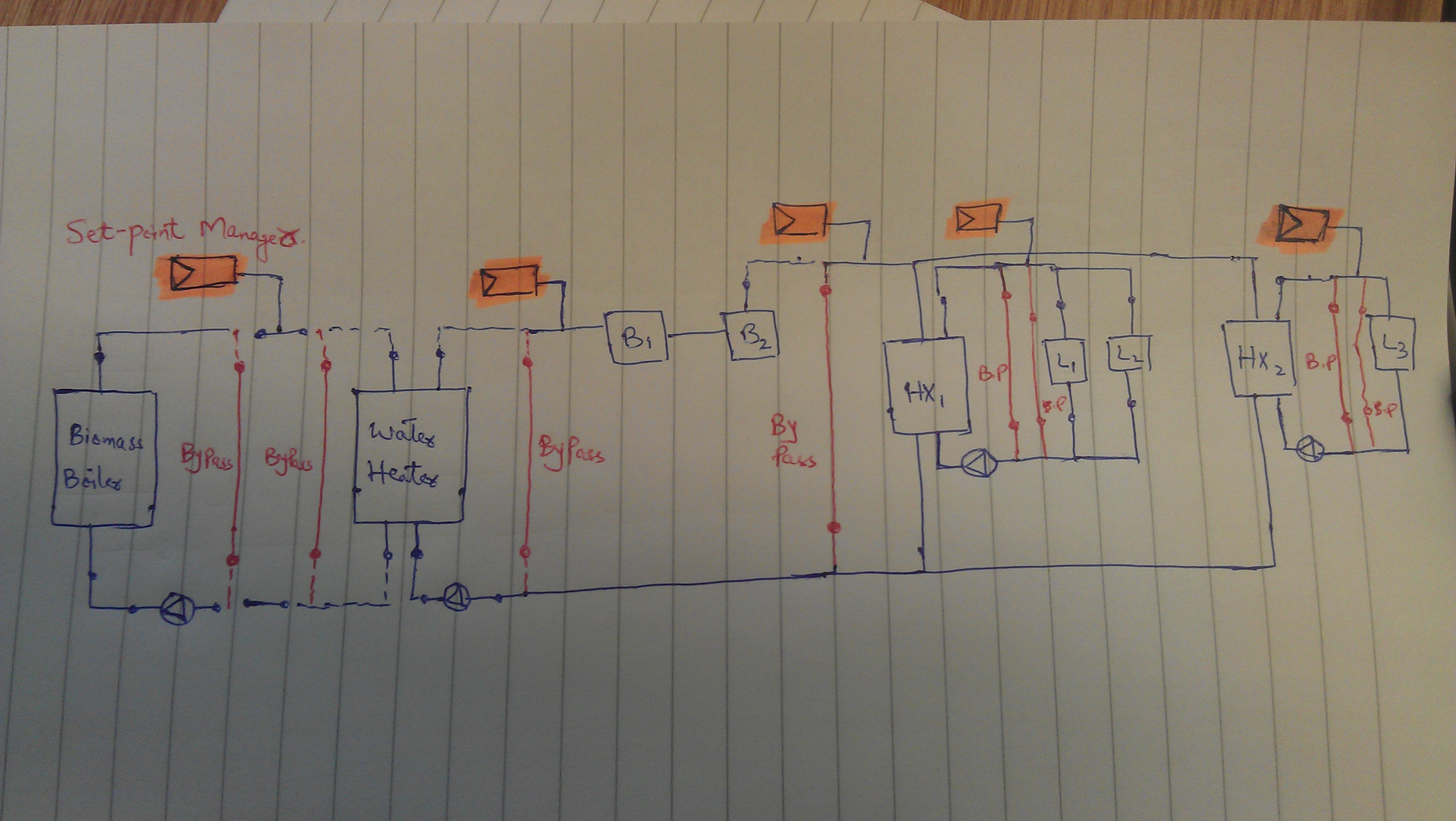

Correct Location of Bypass pipe and set-point managers

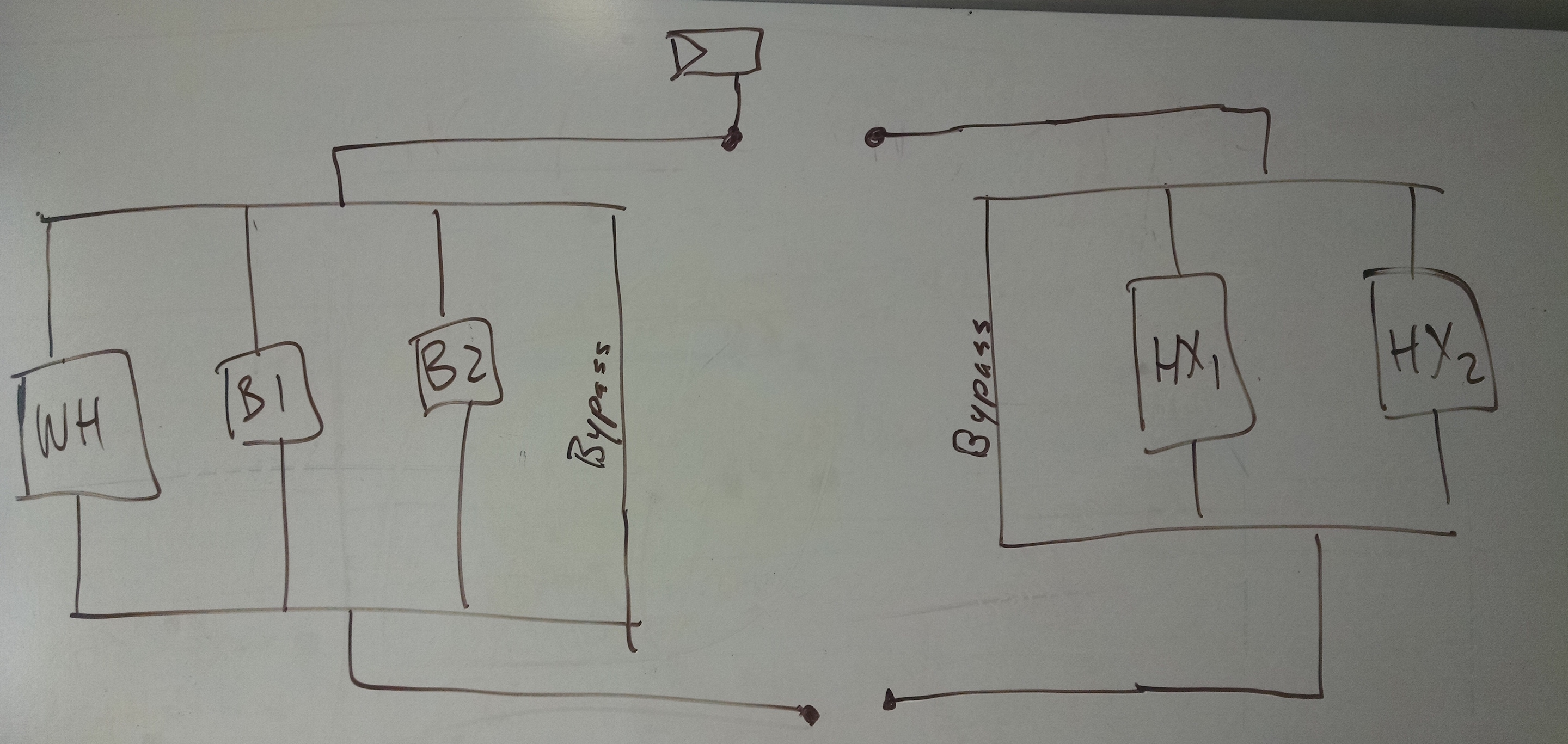

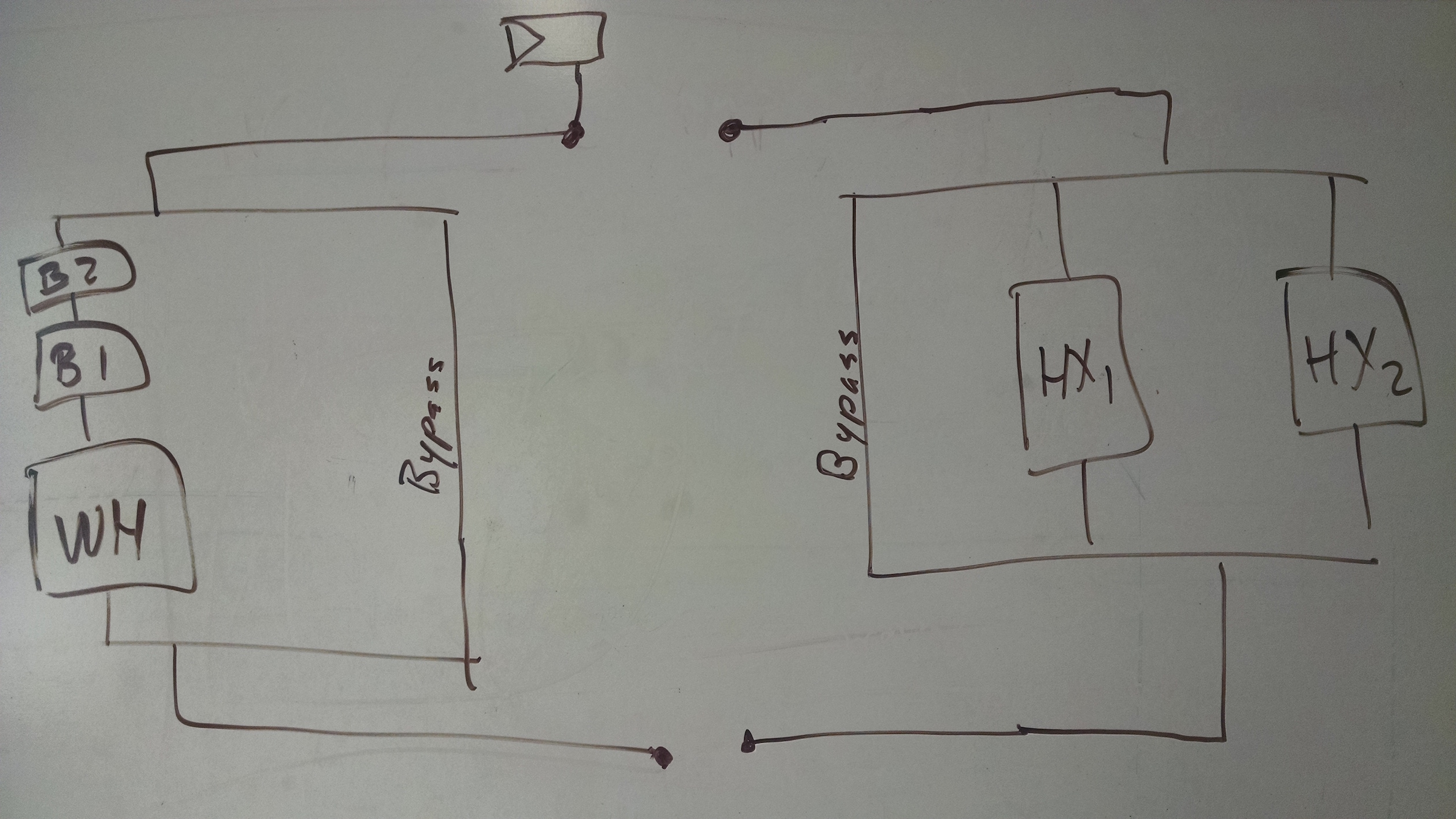

I am modelling a system with biomass boiler, water heater, Gas boilers (B1, B2 in figure below) and two heat exchangers. I have modeled 4 Loops as below;

Loops

- Biomass Loop -- biomass boiler on supply side and Water heater on demand side.

- Hot water Loop -- Water heater, B1 and B2 on supply side (sequential load distribution) and Heat exchangers on demand side.

- Heat exchanger 1 Loop -- Heat exchanger (HX1) on supply side and Loads (L1 and L2) on demand side.

- Heat exchanger 2 Loop -- Heat exchanger (HX2) on supply side and Load (L3) on demand side.

The reason for having two Heat exchangers is to divide the loop into two circuits; constant temperature (serving AHUs) and variable temperature (serving radiant panels). I have few question regarding this setup. Is the set-up in correct configuration i.e. requirement of loops, number of pumps and their position? Also, number of bypass pipes and their position is correct or not?

I have used SetpointManager:Scheduled Set-point managers and was wondering if their position is correct or not? Also, how can I set-up managers to provide variable and constant temperature? One option could be to model variable pump in one of the Heat Exchanger's circuit and constant pump in the other. Any ideas?

Did you figure out how to do constant flow, variable temperature plant loops?

@Julien Marrec: I think it can be done by using constant flow and variable flow pumps, what you recommend?

I think you need:

ConstantFlowSetpointManager:DualSetpointon the supply outlet, and a Plant Loop Demand Calculation Scheme toDualSetpointDeadband(otherwise you get constant temperature at the supply side outlet, right in the middle of the DualSetpoint's Low and High Setpoints)