First time here? Check out the Help page!

| 1 | initial version |

Old question, but I answered a similar question on the Bldg-sim email list that might be helpful. Here's my approach/methodology for and _outdoor_ ice rink in OpenStudio.

I did this in OpenStudio/EnergyPlus, albeit not explicitly because EnergyPlus isn’t currently able to model a PlantLoop using refrigerant as the working fluid.

__System Summary__

Here’s a summary of the system I modeled for an outdoor ~16k ft2 ice rink at a city park in Indiana.

__Methodology__

Here’s the methodology, which I used to claim savings for LEED through an exceptional calculation (no review comments).

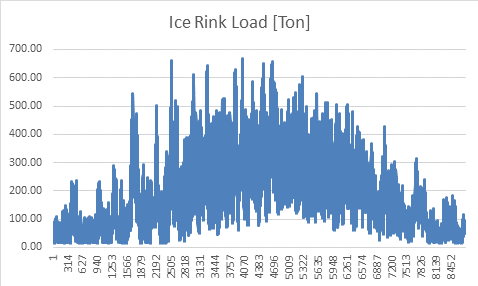

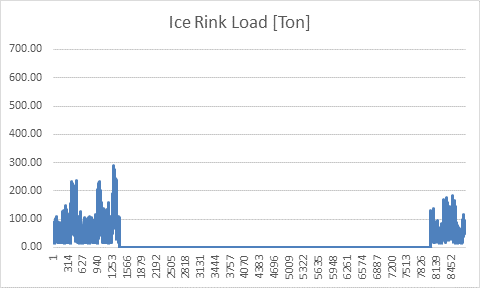

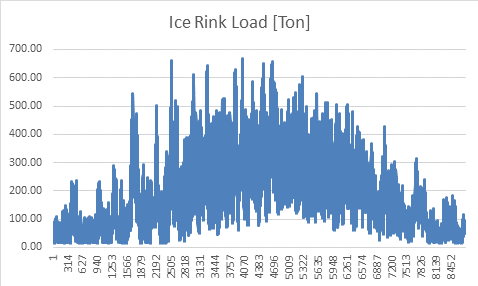

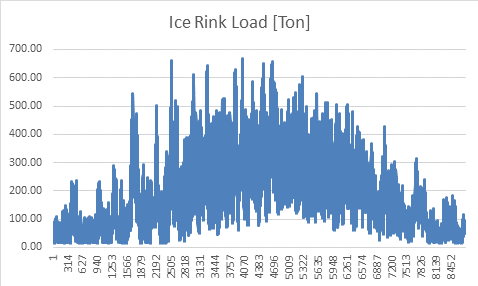

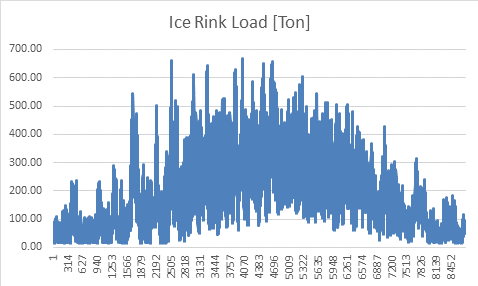

Have the design engineer calculate the hourly cooling load on the plant using the weather data from the TMY file.

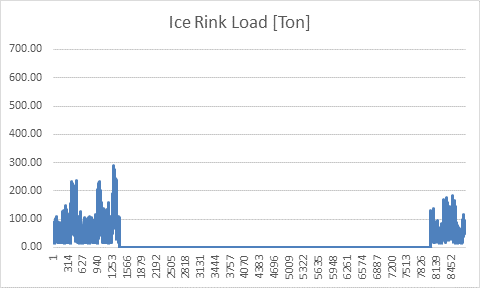

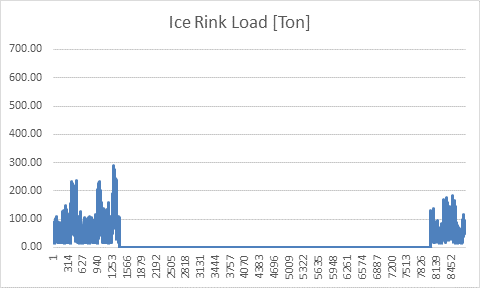

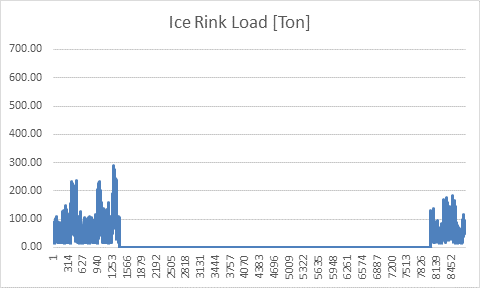

Adjust the cooling load profile to remove loads during the months when the ice rink is not expected to typically operate (Mar – Nov).

Calculate the gross COP of the plant by dividing the total cooling capacity (W) by the total HP (W) of the compressors, pumps, and fans.

Calculate the hourly electrical load of the plant by dividing the hourly cooling load (W) by the COP (W/W).

Determine the peak electrical load of the plant (W).

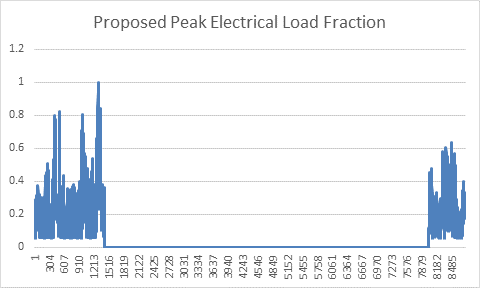

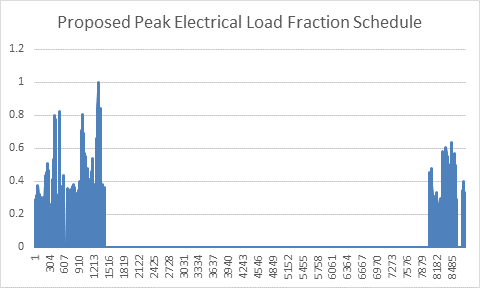

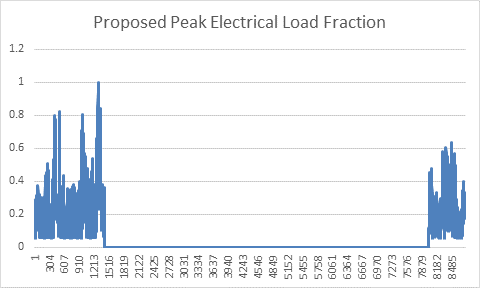

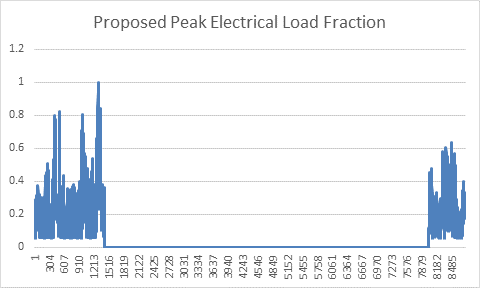

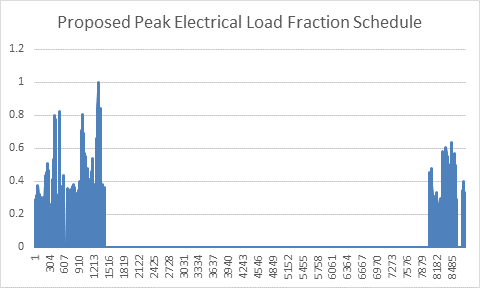

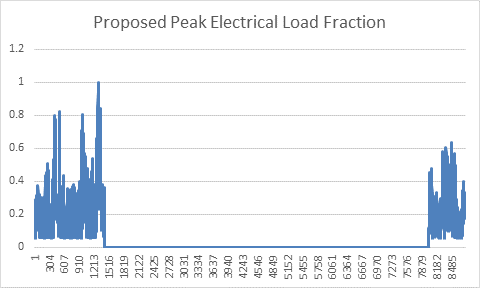

Calculate the hourly peak electrical load fraction by dividing the electrical load for each hour of the year by the peak electrical load, which results in a constant (greater than zero) operating schedule during the ice rink season.

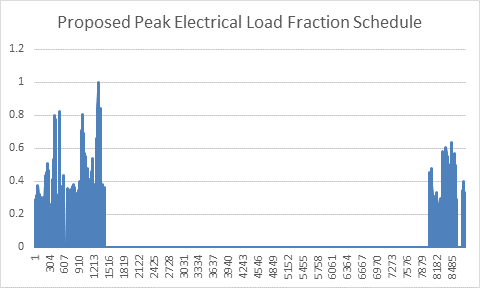

Adjust the peak electrical load fraction profile to account for the system cycling/staging on/off by setting fractions below 25% to zero. This was my main assumption based on the number of compressors, so adjust to fit your project.

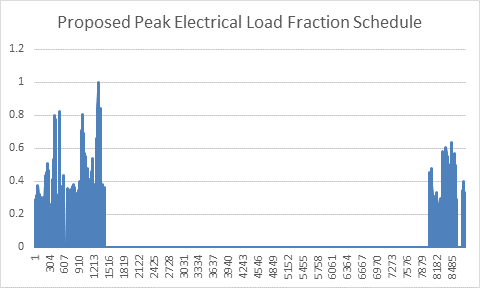

I used a Ruby script to add the annual hourly schedule as a ScheduleFixedInterval object to my model using the OpenStudio API (example).

The ice rink system was modeled using the EnergyPlus object Exterior:FuelEquipment with the Design Level field set to the peak electrical load in (W) and the peak electrical load fraction profile as the Schedule. For each hour of the year, the peak load value is multiplied by the peak load fraction to determine the energy use (Wh) during the simulation. I used an OpenStudio measure to add this object to the model during the simulation.

| 2 | No.2 Revision |

Old question, but I answered a similar question on the Bldg-sim email list that might be helpful. Here's my approach/methodology for and _outdoor_ outdoor ice rink in OpenStudio.

I did this in OpenStudio/EnergyPlus, albeit not explicitly because EnergyPlus isn’t currently able to model a PlantLoop using refrigerant as the working fluid.

__System Summary__System Summary

Here’s a summary of the system I modeled for an outdoor ~16k ft2 ice rink at a city park in Indiana.

__Methodology__Methodology

Here’s the methodology, which I used to claim savings for LEED through an exceptional calculation (no review comments).

Have the design engineer calculate the hourly cooling load on the plant using the weather data from the TMY file.

Adjust the cooling load profile to remove loads during the months when the ice rink is not expected to typically operate (Mar – Nov).Nov, see ASHRAE handbooks).

Calculate the gross COP of the plant by dividing the total cooling capacity (W) by the total HP (W) of the compressors, pumps, and fans.

Calculate the hourly electrical load of the plant by dividing the hourly cooling load (W) by the COP (W/W).

Determine the peak electrical load of the plant (W).

Calculate the hourly peak electrical load fraction by dividing the electrical load for each hour of the year by the peak electrical load, which results in a constant (greater than zero) operating schedule during the ice rink season.

Adjust the peak electrical load fraction profile to account for the system cycling/staging on/off by setting fractions below 25% to zero. This was my main assumption based on the number of compressors, so adjust to fit your project.

I used a Ruby script to add the annual hourly schedule as a ScheduleFixedInterval object to my model using the OpenStudio API (example).

The ice rink system was modeled using the EnergyPlus object Exterior:FuelEquipment with the Design Level field set to the peak electrical load in (W) and the peak electrical load fraction profile as the Schedule. For each hour of the year, the peak load value is multiplied by the peak load fraction to determine the energy use (Wh) during the simulation. I used an OpenStudio measure to add this object to the model during the simulation.

| 3 | No.3 Revision |

Old question, but I answered a similar question on the Bldg-sim email list that might be helpful. Here's my approach/methodology for and outdoor ice rink in OpenStudio.

I did this in OpenStudio/EnergyPlus, albeit not explicitly because EnergyPlus isn’t currently able to model a PlantLoop using refrigerant as the working fluid.

System Summary

Here’s a summary of the system I modeled for an outdoor ~16k ft2 ice rink at a city park in Indiana.

Methodology

Here’s the methodology, which I used to claim savings for LEED through an exceptional calculation (no review comments).

Have the design engineer calculate the hourly cooling load on the plant using the weather data from the TMY file.

Adjust the cooling load profile to remove loads during the months when the ice rink is not expected to typically operate (Mar – Nov, see ASHRAE handbooks).

Calculate the gross COP of the plant by dividing the total cooling capacity (W) by the total HP (W) of the compressors, pumps, and fans.

Calculate the hourly electrical load of the plant by dividing the hourly cooling load (W) by the COP (W/W).

Determine the peak electrical load of the plant (W).

Calculate the hourly peak electrical load fraction by dividing the electrical load for each hour of the year by the peak electrical load, which results in a constant (greater than zero) operating schedule during the ice rink season.

Adjust the peak electrical load fraction profile to account for the system cycling/staging on/off by setting fractions below 25% to zero. This was my main assumption based on the number of compressors, so adjust to fit your project.

I used a Ruby script to add the annual hourly schedule as a ScheduleFixedInterval object to my model using the OpenStudio API (example).(example, but SchedulFile is now available in the OpenStudio SDK).

The ice rink system was modeled using the EnergyPlus object Exterior:FuelEquipment with the Design Level field set to the peak electrical load in (W) and the peak electrical load fraction profile as the Schedule. For each hour of the year, the peak load value is multiplied by the peak load fraction to determine the energy use (Wh) during the simulation. I used an OpenStudio measure to add this object to the model during the simulation.

| 4 | No.4 Revision |

Old question, but I answered a similar question one on the Bldg-sim email list that might be helpful. Here's my approach/methodology for and an outdoor ice rink in OpenStudio.

I did this in OpenStudio/EnergyPlus, albeit not explicitly because EnergyPlus isn’t currently able to model a PlantLoop using refrigerant as the working fluid.

Here’s a summary of the system I modeled for an outdoor ~16k ft2 ice rink at a city park in Indiana.

Here’s the methodology, which I used to claim savings for LEED through an exceptional calculation (no review comments).

Have the design engineer calculate the hourly cooling load on the plant using the weather data from the TMY file.

Adjust the cooling load profile to remove loads during the months when the ice rink is not expected to typically operate (Mar – Nov, see ASHRAE handbooks).

Calculate the gross COP of the plant by dividing the total cooling capacity (W) by the total HP (W) of the compressors, pumps, and fans.

Calculate the hourly electrical load of the plant by dividing the hourly cooling load (W) by the COP (W/W).

Determine the peak electrical load of the plant (W).

Calculate the hourly peak electrical load fraction by dividing the electrical load for each hour of the year by the peak electrical load, which results in a constant (greater than zero) operating schedule during the ice rink season.

Adjust the peak electrical load fraction profile to account for the system cycling/staging on/off by setting fractions below 25% to zero. This was my main assumption based on the number of compressors, so adjust to fit your project.

I used a Ruby script to add the annual hourly schedule as a ScheduleFixedInterval object to my model using the OpenStudio API (example, but SchedulFile is now available in the OpenStudio SDK).

The ice rink system was modeled using the EnergyPlus object Exterior:FuelEquipment with the Design Level field set to the peak electrical load in (W) and the peak electrical load fraction profile as the Schedule. For each hour of the year, the peak load value is multiplied by the peak load fraction to determine the energy use (Wh) during the simulation. I used an OpenStudio measure to add this object to the model during the simulation.