First time here? Check out the Help page!

| 1 | initial version |

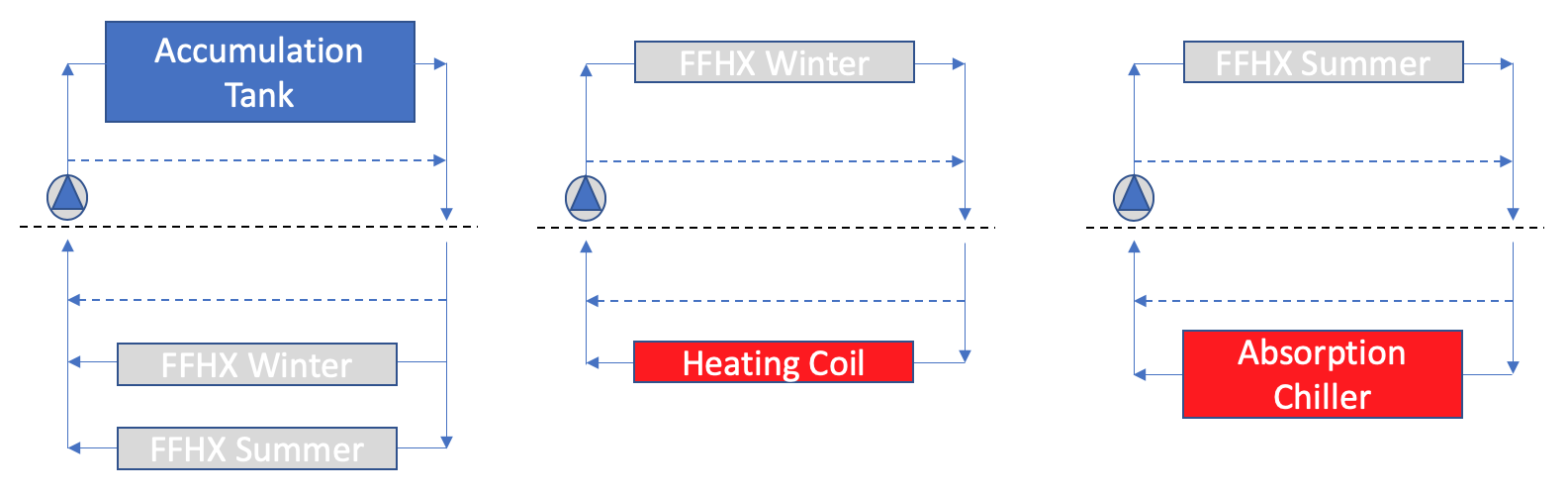

1 - To get around the limit of one splitter / mixer pair per plant loop, you will need a total of three plant loops and two ideal fluid-to-fluid heat exchangers (FFHX). To achieve this, set the Heat Exchange model Type input field to Ideal.

Below is a diagram of these connections (not as nice as yours :) )

You'll need to play around with the other FFHX inputs like Availability Schedule Name and Control Type for operational controls.

2 - Yes, you could add a plant loop component on the demand side as a heating load using the LoadProfile:Plant object instead of a heating coil. This requires you to provide a schedule of heating load values. If you don't have that information, then you may need to define the heating coil-to-boiler plant loop as well.