| 1 | initial version |

The DX coil model will simulate the coil at full flow and capacity to determine the performance. Then the model will set the outlet conditions based on cycling or constant fan choice. For cycling fan the outlet conditions are full capacity T/w and average air mass flow rate based on PLR. For constant fan the outlet conditions are average T/w based on PLR and whatever flow rate the coil is currently operating. When air flow is lower than expected, very cold outlet temperature is calculated and hence the warnings/fatal. So if the lower air flow rate corresponds to a lower compressor speed, then yes a multi-stage or multi-speed coil model is needed.

| 2 | No.2 Revision |

The DX coil model will simulate the coil at full flow and capacity to determine the performance. Then the model will set the outlet conditions based on cycling or constant fan choice. For cycling fan the outlet conditions are full capacity T/w and average air mass flow rate based on PLR. For constant fan the outlet conditions are average T/w based on PLR and whatever flow rate the coil is currently operating. When air flow is lower than expected, very cold outlet temperature is calculated and hence the warnings/fatal. So if the lower air flow rate corresponds to a lower compressor speed, then yes a multi-stage or multi-speed coil model is needed.

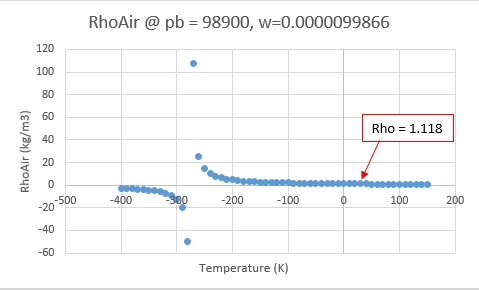

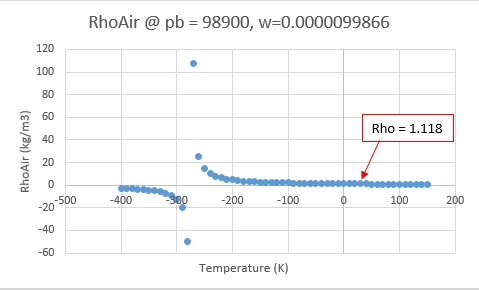

At those conditions the empirical model thinks density is negative. The low air flow rate at high compressor capacity is causing very low outlet air temperature and humidity ratio.

| 3 | No.3 Revision |

The DX coil model will simulate the coil at full flow and capacity to determine the performance. Then the model will set the outlet conditions based on cycling or constant fan choice. For cycling fan the outlet conditions are full capacity T/w and average air mass flow rate based on PLR. For constant fan the outlet conditions are average T/w based on PLR and whatever flow rate the coil is currently operating. When air flow is lower than expected, very cold outlet temperature is calculated and hence the warnings/fatal. So if the lower air flow rate corresponds to a lower compressor speed, then yes a multi-stage or multi-speed coil model is needed.

At those conditions the empirical model thinks density is negative. The low air flow rate at high compressor capacity is causing very low outlet air temperature and humidity ratio.

rhoair = (pb / (287.0 * (tdb + 273.15) * (1.0 + 1.6077687 * max(w, 1.0e-5))));

pb = barometric pressure

tdb = temperature

w = humidity ratio