| 1 | initial version |

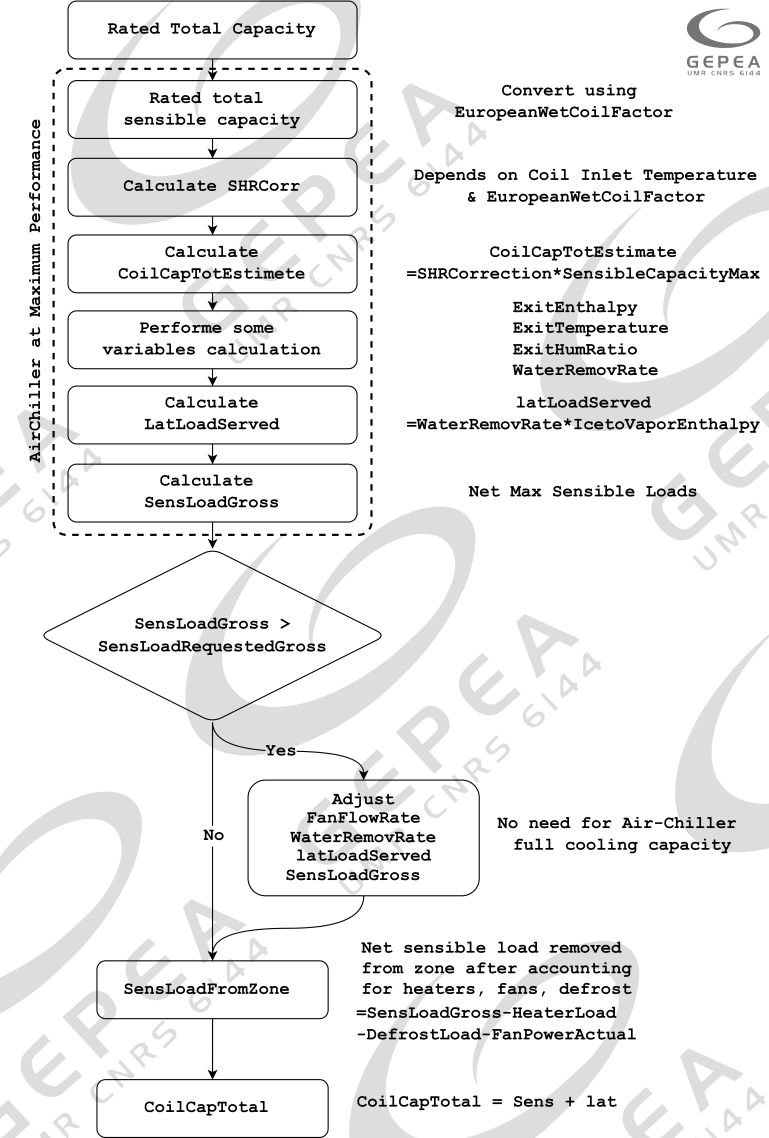

I appreciate your assistance, @rraustad; it proved to be quite helpful. I believe I now have a better understanding of the refrigeration model and have created the flowchart below after reviewing the code in "RefrigeratedCase.cc."

I still have a question about the airchiller object, specifically the Coil Material Correction and Refrigerant Correction coefficients. In the Refrigeration model code snippet, I noticed these coefficients are mentioned only three times, and a comment mentioned that they're ONLY used if the Capacity Rating Type is CapacityTotalSpecificConditions

// Correction factor from manufacturer's rating for coil material, default 1.0

++NumNum; // N7

WarehouseCoil(CoilID).CorrMaterial = 1.0; // default value

if (!lNumericBlanks(NumNum)) WarehouseCoil(CoilID).CorrMaterial = Numbers(NumNum);

// Correction factor from manufacturer's rating for refrigerant, default 1.0

++NumNum; // N8

WarehouseCoil(CoilID).CorrRefrigerant = 1.0; // default value

if (!lNumericBlanks(NumNum)) WarehouseCoil(CoilID).CorrRefrigerant = Numbers(NumNum);

// ONLY used if the Capacity Rating Type is CapacityTotalSpecificConditions

// Convert all European sensible capacities to sensible load factors

if ((WarehouseCoil(CoilID).ratingType != RatingType::UnitLoadFactorSens) &&

(WarehouseCoil(CoilID).ratingType != RatingType::RatedCapacityTotal))

WarehouseCoil(CoilID).UnitLoadFactorSens = WarehouseCoil(CoilID).RatedSensibleCap / WarehouseCoil(CoilID).RatedTemperatureDif;

// Now have UnitLoadFactorSens for all except RatingType == RatedCapacityTotal

// Apply material and refrigerant correction factors to sensible load factors

if ((WarehouseCoil(CoilID).ratingType != RatingType::RatedCapacityTotal))

WarehouseCoil(CoilID).UnitLoadFactorSens *= WarehouseCoil(CoilID).CorrMaterial * WarehouseCoil(CoilID).CorrRefrigerant;

// First calc of ratedsensiblecap for type type unitloadfactorsens

WarehouseCoil(CoilID).RatedSensibleCap = WarehouseCoil(CoilID).UnitLoadFactorSens * WarehouseCoil(CoilID).RatedTemperatureDif;

However, at the beginning of the airchiller subroutine you provided, there's a comment stating, Correction factors for material and refrigerant are applied to all of these ratings. and I couldn't find where these coefficients are used for the European Standard Ratings. Just so you know, when I change the value from the default (which is 1), it affects the airchiller performance.

Any information on these coefficients?

// The air chiller performance is based on three types of manufacturers ratings,

// Unit Load Factor, Total Capacity Map, or a set of European standards.

// Correction factors for material and refrigerant are applied to all of these ratings.

| 2 | No.2 Revision |

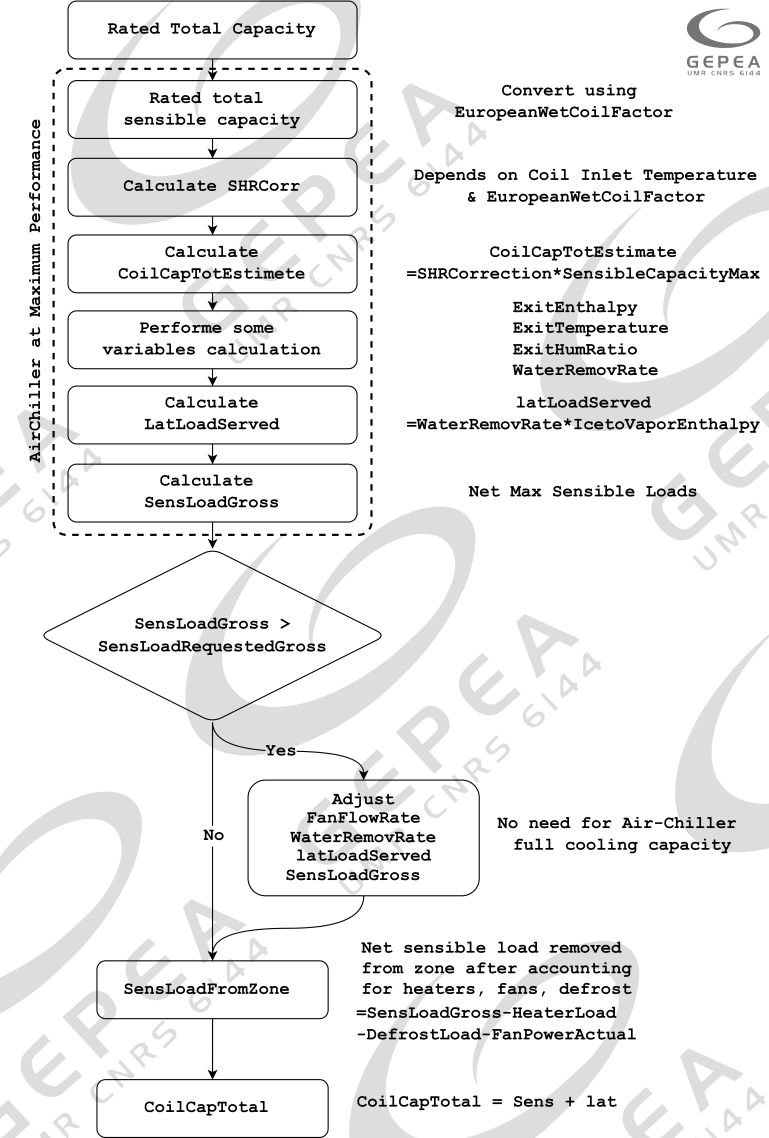

I appreciate your assistance, @rraustad; it proved to be quite helpful. I believe I now have a better understanding of the refrigeration model and have created the flowchart below after reviewing the code in "RefrigeratedCase.cc."

I There's one thing I'm still have a question about the airchiller object, unsure about, specifically the Coil Material Correction and Refrigerant Correction coefficients. In the Refrigeration model code snippet, I noticed these coefficients are mentioned only three times, and a comment mentioned that they're ONLY used if the Capacity Rating Type is CapacityTotalSpecificConditions

// Correction factor from manufacturer's rating for coil material, default 1.0

++NumNum; // N7

WarehouseCoil(CoilID).CorrMaterial = 1.0; // default value

if (!lNumericBlanks(NumNum)) WarehouseCoil(CoilID).CorrMaterial = Numbers(NumNum);

// Correction factor from manufacturer's rating for refrigerant, default 1.0

++NumNum; // N8

WarehouseCoil(CoilID).CorrRefrigerant = 1.0; // default value

if (!lNumericBlanks(NumNum)) WarehouseCoil(CoilID).CorrRefrigerant = Numbers(NumNum);

// ONLY used if the Capacity Rating Type is CapacityTotalSpecificConditions

// Convert all European sensible capacities to sensible load factors

if ((WarehouseCoil(CoilID).ratingType != RatingType::UnitLoadFactorSens) &&

(WarehouseCoil(CoilID).ratingType != RatingType::RatedCapacityTotal))

WarehouseCoil(CoilID).UnitLoadFactorSens = WarehouseCoil(CoilID).RatedSensibleCap / WarehouseCoil(CoilID).RatedTemperatureDif;

// Now have UnitLoadFactorSens for all except RatingType == RatedCapacityTotal

// Apply material and refrigerant correction factors to sensible load factors

if ((WarehouseCoil(CoilID).ratingType != RatingType::RatedCapacityTotal))

WarehouseCoil(CoilID).UnitLoadFactorSens *= WarehouseCoil(CoilID).CorrMaterial * WarehouseCoil(CoilID).CorrRefrigerant;

// First calc of ratedsensiblecap for type type unitloadfactorsens

WarehouseCoil(CoilID).RatedSensibleCap = WarehouseCoil(CoilID).UnitLoadFactorSens * WarehouseCoil(CoilID).RatedTemperatureDif;

However, at the beginning of the airchiller subroutine you provided, there's a comment stating, Correction factors for material and refrigerant are applied to all of these ratings. and I couldn't find where these coefficients are used for the European Standard Ratings. Just so you know, when I change the value from the default (which is 1), it affects the airchiller performance.

Any information on these coefficients?

// The air chiller performance is based on three types of manufacturers ratings,

// Unit Load Factor, Total Capacity Map, or a set of European standards.

// Correction factors for material and refrigerant are applied to all of these ratings.

| 3 | No.3 Revision |

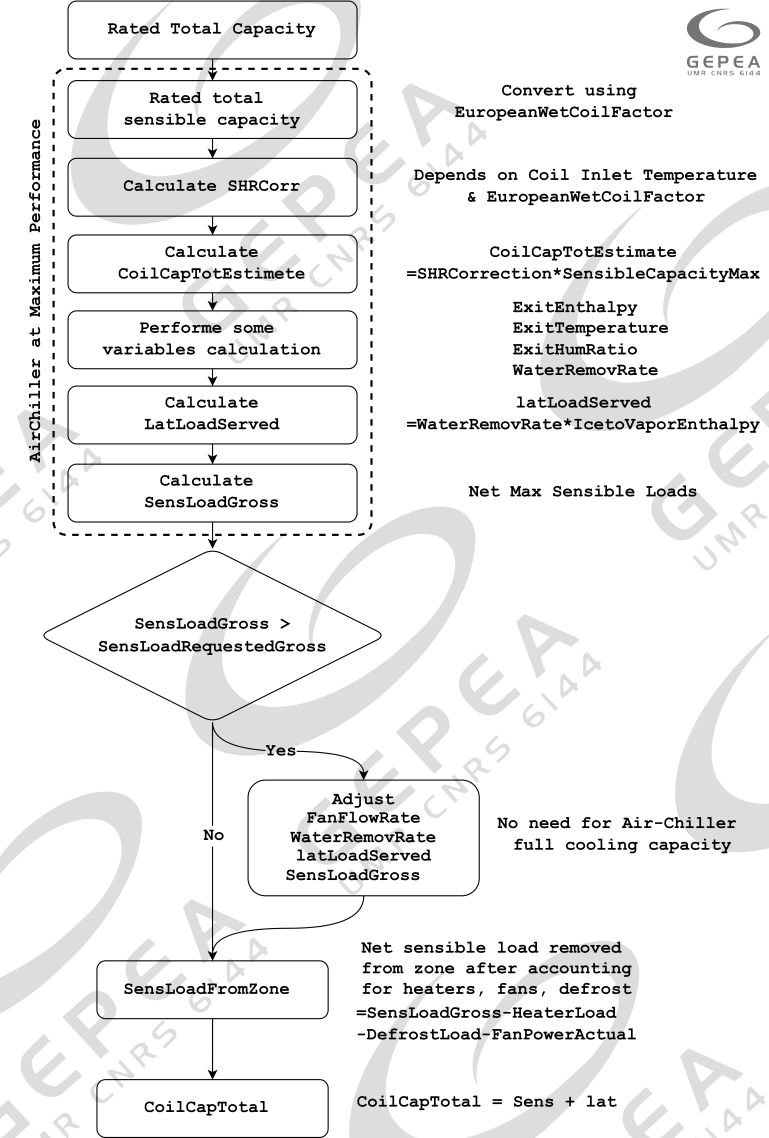

I appreciate your assistance, answer, @rraustad; it proved to be quite helpful. really made things clearer for me. I believe I now have a better understanding of the refrigeration model and have created the flowchart below after reviewing the code in "RefrigeratedCase.cc."

There's one thing I'm still unsure about, specifically the Coil Material Correction and Refrigerant Correction coefficients. In the Refrigeration model code snippet, I noticed these coefficients are mentioned only three times, and a comment mentioned that they're ONLY used if the Capacity Rating Type is CapacityTotalSpecificConditions

// Correction factor from manufacturer's rating for coil material, default 1.0

++NumNum; // N7

WarehouseCoil(CoilID).CorrMaterial = 1.0; // default value

if (!lNumericBlanks(NumNum)) WarehouseCoil(CoilID).CorrMaterial = Numbers(NumNum);

// Correction factor from manufacturer's rating for refrigerant, default 1.0

++NumNum; // N8

WarehouseCoil(CoilID).CorrRefrigerant = 1.0; // default value

if (!lNumericBlanks(NumNum)) WarehouseCoil(CoilID).CorrRefrigerant = Numbers(NumNum);

// ONLY used if the Capacity Rating Type is CapacityTotalSpecificConditions

// Convert all European sensible capacities to sensible load factors

if ((WarehouseCoil(CoilID).ratingType != RatingType::UnitLoadFactorSens) &&

(WarehouseCoil(CoilID).ratingType != RatingType::RatedCapacityTotal))

WarehouseCoil(CoilID).UnitLoadFactorSens = WarehouseCoil(CoilID).RatedSensibleCap / WarehouseCoil(CoilID).RatedTemperatureDif;

// Now have UnitLoadFactorSens for all except RatingType == RatedCapacityTotal

// Apply material and refrigerant correction factors to sensible load factors

if ((WarehouseCoil(CoilID).ratingType != RatingType::RatedCapacityTotal))

WarehouseCoil(CoilID).UnitLoadFactorSens *= WarehouseCoil(CoilID).CorrMaterial * WarehouseCoil(CoilID).CorrRefrigerant;

// First calc of ratedsensiblecap for type type unitloadfactorsens

WarehouseCoil(CoilID).RatedSensibleCap = WarehouseCoil(CoilID).UnitLoadFactorSens * WarehouseCoil(CoilID).RatedTemperatureDif;

However, at the beginning of the airchiller subroutine you provided, there's a comment stating, Correction factors for material and refrigerant are applied to all of these ratings. and I couldn't find where these coefficients are used for the European Standard Ratings. Just so you know, when I change the value from the default (which is 1), it affects the airchiller performance.

Any information on these coefficients?

// The air chiller performance is based on three types of manufacturers ratings,

// Unit Load Factor, Total Capacity Map, or a set of European standards.

// Correction factors for material and refrigerant are applied to all of these ratings.