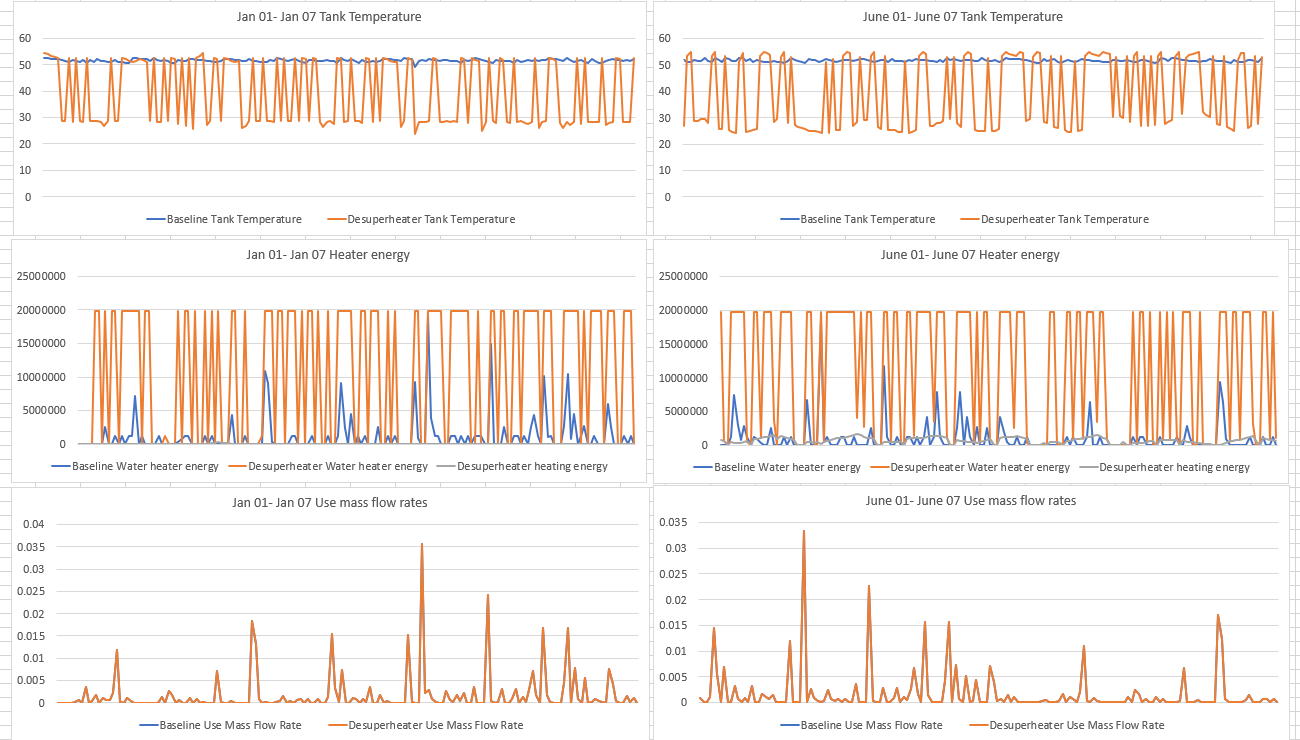

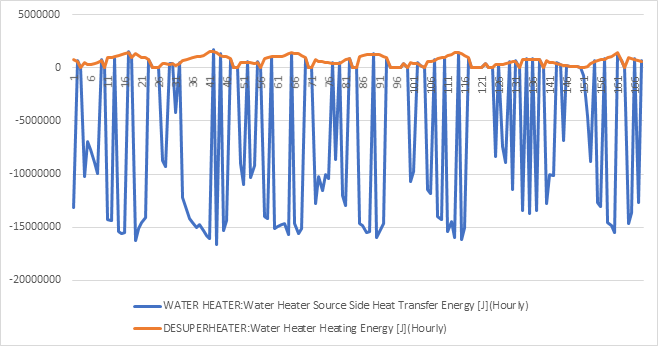

Previously, I modeled a water system with desuperheater in Model 1 which gave happy results (about half water heating energy saving). Now I need to integrate this technology into another model( Model2) with exactly the same approach. However, the Model 2 results showed about 10X water heating energy usage than its baseline, which is unreasonable.

The approach I used to model desuperheater is quite straightforward, I'd like to elaborate as following:

- I created a constant temperature schedule of 55C (setpoint is 52.6667C)

.

Schedule:Constant,

desuperheaterStp, !- Name

Temperature, !- Schedule Type Limits Name

55; !- Hourly Value

- I used

Coil:WaterHeating:Desuperheaterobject, the snippet was like

.

Coil:WaterHeating:Desuperheater,

Desuperheater, !- Name

, !- Availability Schedule Name

desuperheaterStp, !- Setpoint Temperature Schedule Name

2, !- Dead Band Temperature Difference {deltaC}

0.25, !- Rated Heat Reclaim Recovery Efficiency

50, !- Rated Inlet Water Temperature {C}

35, !- Rated Outdoor Air Temperature {C}

60, !- Maximum Inlet Water Temperature for Heat Reclaim {C}

, !- Heat Reclaim Efficiency Function of Temperature Curve Name

DesuperheaterIn, !- Water Inlet Node Name

DesuperheaterOut, !- Water Outlet Node Name

WaterHeater:Mixed, !- Tank Object Type

water heater, !- Tank Name

Coil:Cooling:DX:SingleSpeed, !- Heating Source Object Type

central ac clg coil, !- Heating Source Name

0.001, !- Water Flow Rate {m3/s}

, !- Water Pump Power {W}

0.2; !- Fraction of Pump Heat to Water

- And finally I got these two water nodes connected with

WaterHeater:Mixed

.

WaterHeater:Mixed,

res wh, !- Name

0.136274824222915, !- Tank Volume {m3}

WH Setpoint Temp, !- Setpoint Temperature Schedule Name

2, !- Deadband Temperature Difference {deltaC}

99, !- Maximum Temperature Limit {C}

Cycle, !- Heater Control Type

5500.06477392209, !- Heater Maximum Capacity {W}

0, !- Heater Minimum Capacity {W}

0, !- Heater Ignition Minimum Flow Rate {m3/s}

0, !- Heater Ignition Delay {s}

Electricity, !- Heater Fuel Type

0.8, !- Heater Thermal Efficiency

, !- Part Load Factor Curve Name

0, !- Off Cycle Parasitic Fuel Consumption Rate {W}

Electricity, !- Off Cycle Parasitic Fuel Type

0, !- Off Cycle Parasitic Heat Fraction to Tank

0, !- On Cycle Parasitic Fuel Consumption Rate {W}

Electricity, !- On Cycle Parasitic Fuel Type

0, !- On Cycle Parasitic Heat Fraction to Tank

Outdoors, !- Ambient Temperature Indicator

, !- Ambient Temperature Schedule Name

, !- Ambient Temperature Zone Name

Model Outdoor Air Node, !- Ambient Temperature Outdoor Air Node Name

0.704227539803499, !- Off Cycle Loss Coefficient to Ambient Temperature {W/K}

1, !- Off Cycle Loss Fraction to Zone

0.704227539803499, !- On Cycle Loss Coefficient to Ambient Temperature {W/K}

1, !- On Cycle Loss Fraction to Zone

, !- Peak Use Flow Rate {m3/s}

, !- Use Flow Rate Fraction Schedule Name

, !- Cold Water Supply Temperature Schedule Name

Node 13, !- Use Side Inlet Node Name

Node 14, !- Use Side Outlet Node Name

1, !- Use Side Effectiveness

DesuperheaterOut, !- Source Side Inlet Node Name

DesuperheaterIn, !- Source Side Outlet Node Name

1, !- Source Side Effectiveness

Autosize, !- Use Side Design Flow Rate {m3/s}

Autosize, !- Source Side Design Flow Rate {m3/s}

1.5, !- Indirect Water Heating Recovery Time {hr}

IndirectHeatPrimarySetpoint, !- Source Side Flow Control Mode

, !- Indirect Alternate Setpoint Temperature Schedule Name

General; !- End-Use Subcategory

Water system energy results:

Model1

- Baseline : 13.21

- Desuperheater : 6.07

Model2

- Baseline : 11.09

- Desuperheater : 119.2