I have a Pump:ConstantSpeed on a heating plant loop serving nine Coil:Heating:Water. The Pump Control Type is set to intermittent...

Pump:ConstantSpeed,

Hot Water Loop: Old: Pump - Constant Speed, !- Name

Node 233, !- Inlet Node Name

Node 239, !- Outlet Node Name

Autosize, !- Design Flow Rate {m3/s}

74726.673, !- Design Pump Head {Pa}

Autosize, !- Design Power Consumption {W}

0.84, !- Motor Efficiency

0, !- Fraction of Motor Inefficiencies to Fluid Stream

Intermittent; !- Pump Control Type

According to the input output reference for Pump:ConstantSpeed

If there is no load on the loop and the pump is operating intermittently, then the pump can shutdown.

There is a caveat about an availability manager being able to force the pump on/off, but I have no availability managers assigned to the loop.

PlantLoop,

Hot Water Loop: Old, !- Name

Water, !- Fluid Type

, !- User Defined Fluid Type

Hot Water Loop: Old Operation Schemes, !- Plant Equipment Operation Scheme Name

Node 234, !- Loop Temperature Setpoint Node Name

100, !- Maximum Loop Temperature {C}

0, !- Minimum Loop Temperature {C}

Autosize, !- Maximum Loop Flow Rate {m3/s}

0, !- Minimum Loop Flow Rate {m3/s}

Autocalculate, !- Plant Loop Volume {m3}

...

...

Optimal, !- Load Distribution Scheme

, !- Availability Manager List Name

SingleSetpoint, !- Plant Loop Demand Calculation Scheme

; !- Common Pipe Simulation

And the operation scheme...

PlantEquipmentOperationSchemes,

Hot Water Loop: Old Operation Schemes, !- Name

PlantEquipmentOperation:HeatingLoad, !- Control Scheme Object Type 1

Plant Equipment Operation Heating Load 2, !- Control Scheme Name 1

Always On Discrete; !- Control Scheme Schedule Name 1

PlantEquipmentOperation:HeatingLoad,

Plant Equipment Operation Heating Load 2, !- Name

0, !- Load Range Lower Limit 1 {W}

1000000000, !- Load Range Upper Limit 1 {W}

Plant Equipment Operation Heating Load 2 equipment list 1; !- Range Equipment List Name 1

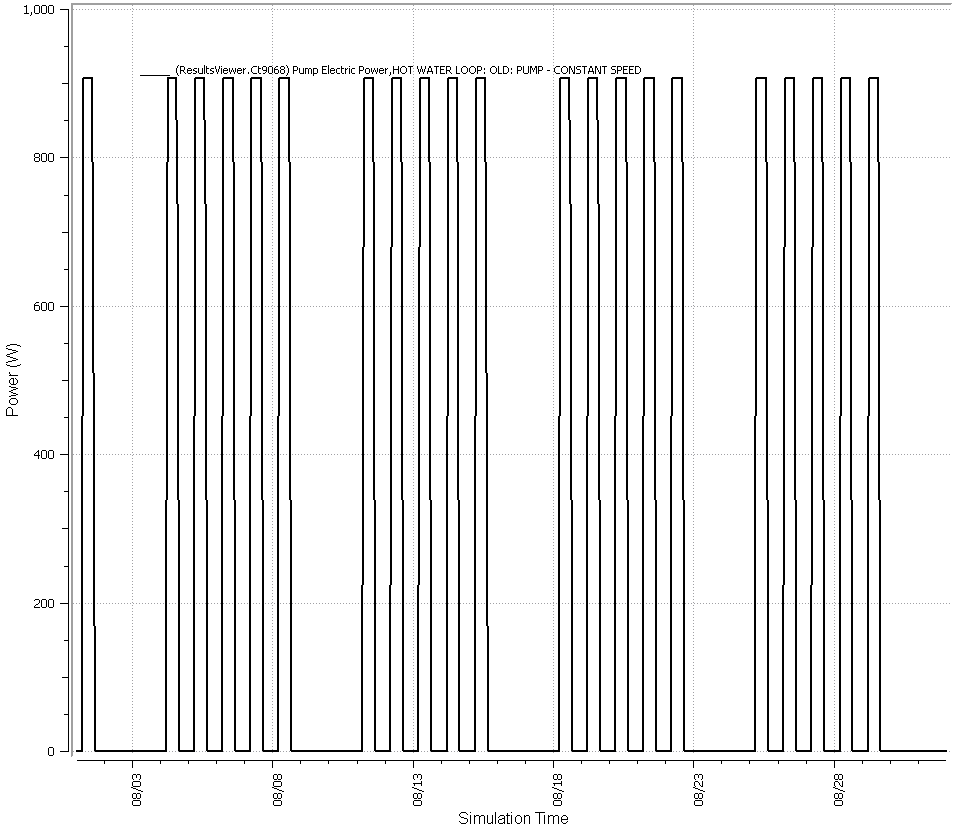

So I'd expect that if there is no load on the demand side of the loop, then the pump would turn off, but this doesn't appear to be the case.

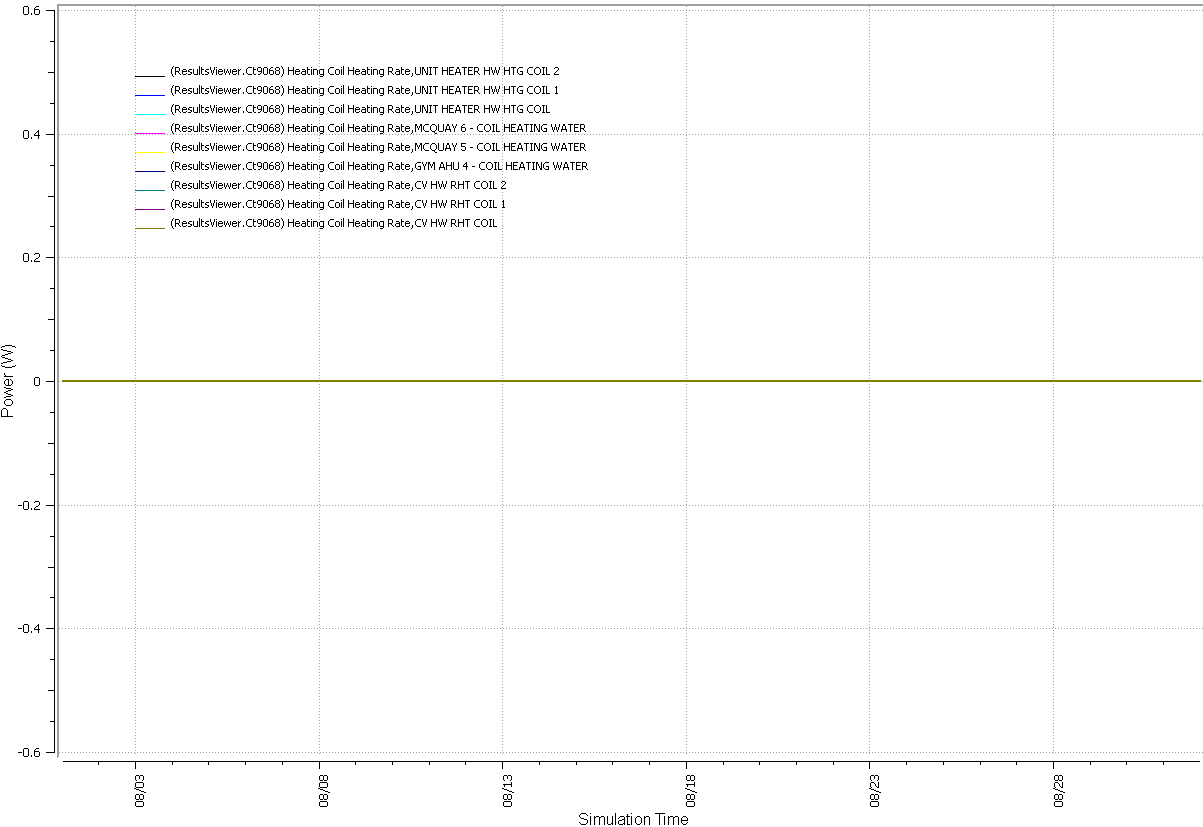

In August, the heating rate on all the relevant coils is 0.

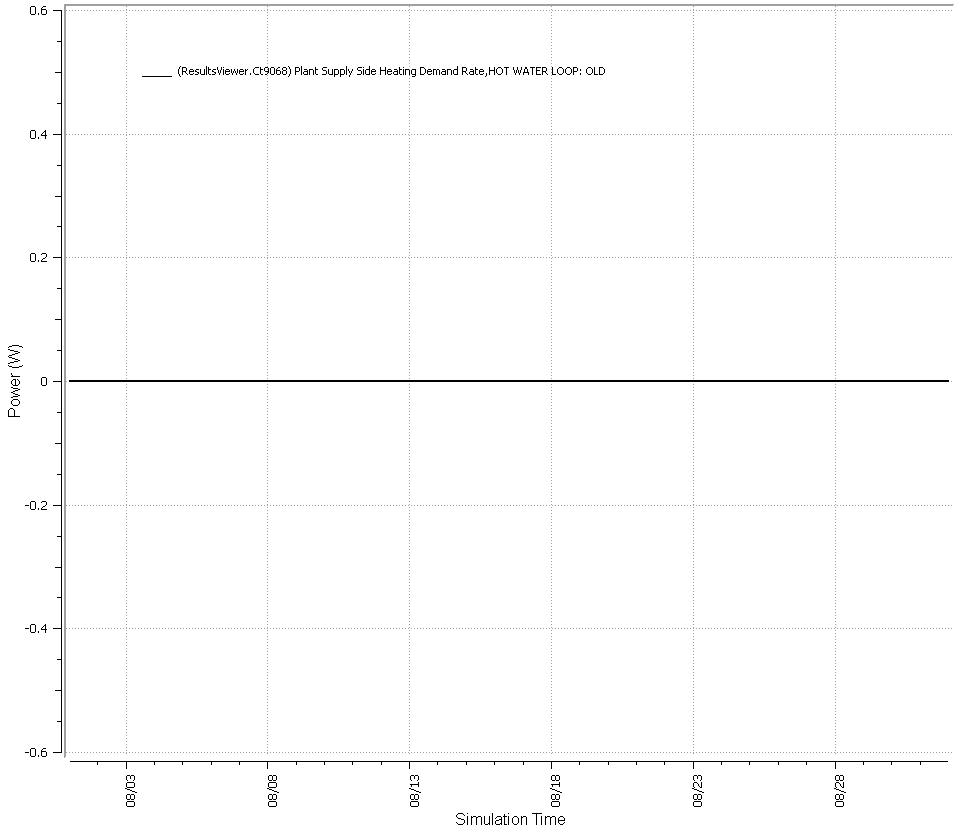

Which yields no demand on the plant.

And yet we can see the pump turning on for the same schedule that the air loops associated with the coils are on.

The only supply equipment for the loop is a HeatExchanger:FluidToFluid and my best guess is that this is somehow making a flow request, but that doesn't really make sense. The loop also realizes that it's above setpoint and there is 'cooling load' on the loop, so is it trying to cool the loop down even though there is no equipment that can satisfy a cooling load? Other ideas?