Hello,

As a new Open Studio user, I conducted a bunch of simulations to understand the impact of different parameters. Among these simulations, a case bothers me.

(Sorry, but as a new user I cannot post pictures... I had to insert links to files)

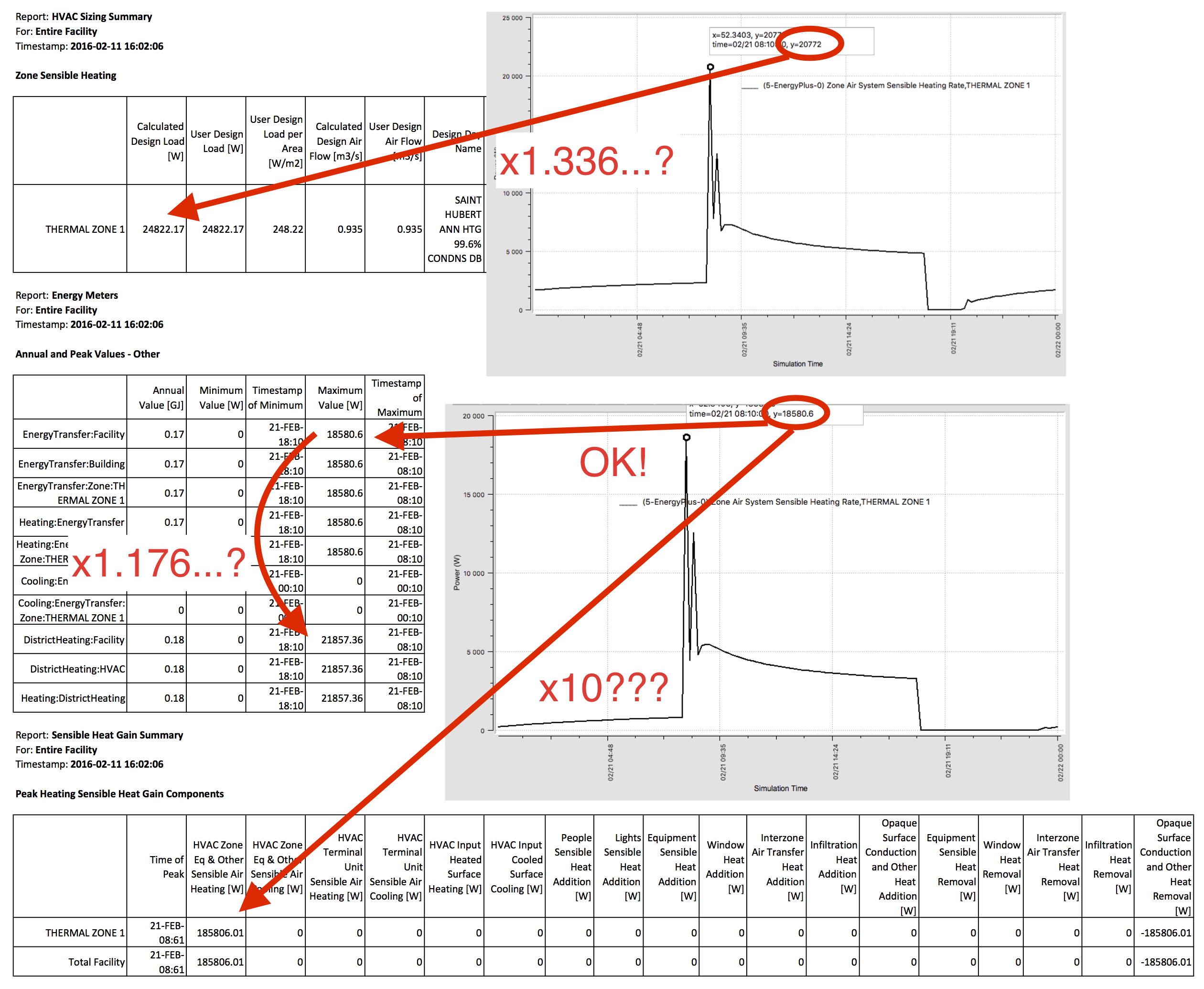

The basic version consists of a simple cube (no windows, no internal gains, no infiltration, no ventilation ...). The temperature is set to 22 °C (constant) and I make use of the "ideal air loads system". The results seem consistent (see green values in the file, which are also found in the graph)

Results without nighttime-reduced temperature

The second version is identical but incorporating a temperature reduction at night and on weekends (16°C instead of 22°C). Of course I understand that some heating-up capacity is necessary, but this does not explain all the results.

Results with nighttime-reduced temperature

- "calculated design load" is identical in both cases, which makes sense

- in the basic version, "district heating" is 3137.46W and corresponds to the peak on the graph : OK

- in the modified version, "district heating" is 23513.39W (almost 8 x higher). This value does not match the peak on the graph (about 9750 W). Is there an explanation?

- in "energy meters", why is "Energy Transfer Partners: Facility" (20183.82 W) slightly different than "DistrictHeating:Facility" (23513.39 W) ?

- where does "HVAC area eq. & Other sensitive air heating" value (188925.97 W) come from ?

Could you help me? Am I missing something?

I understand that this is an "extreme" case, and that in reality the differences will be smaller thanks to internal and solar gains (I tried a real case, and there is an order of magnitude of +/- 2).

Without modeling a complete HVAC system, is there a way to get closer to a real heating system (with limited capacity)?

Thank you very much for your time.

Nicolas