I want to model an AWHP with different outlet setpoint temperatures for the water: 35°C for underfloor heating and 60°C for DHW (with a tank). Additionally, the system should have different operating times during the day, as the HP provides either SH or DHW, but not both simultaneously. Typically, this is managed by prioritizing DHW during peak demand times, while SH operates when hot water is not required. The system may have minimum and maximum operation times for each function to ensure efficient performance and maintain comfort levels.

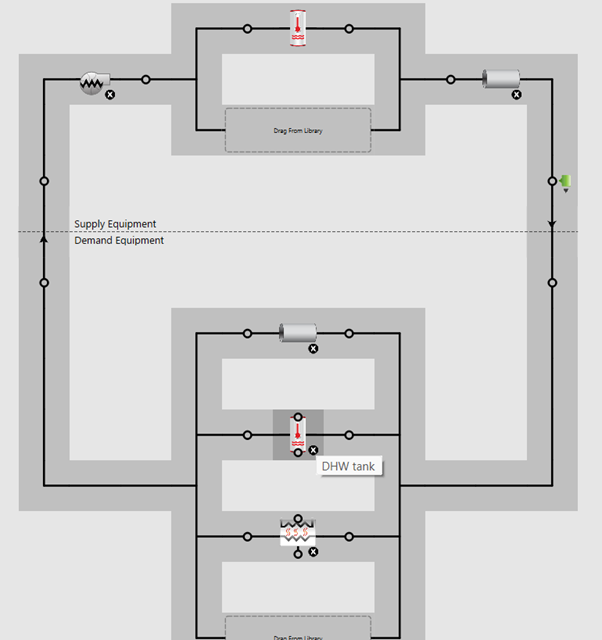

Currently, using a HeatPumpWaterHeater, I have only one compressor setpoint temperature of 60°C, which is used for the DHW tank, and the water is then cooled to 35°C for space heating through an HX. However, this does not reflect my goal of having two different compressor setpoints for SH and DHW.

Is the HeatPumpWaterHeater zone equipment unsuitable for this case? How would it be appropriate to model the system? Would EMS control be necessary?