Issues with Walk-in Freezer Temperature Fluctuations Despite Adjusting Compressor's Cooling Capacity in EnergyPlus Model

Hello everyone,

Following the two old post here: post 1 and here: post 2, I am still trying to model a walk-in freezer (3L x 4W x 2.7H cold room storage) using EnergyPlus and specifically utilizing the Refrigeration: AirChiller object. The model is based on the RefrigeratedWarehouse example. The walk-in setpoint is -22°C ± 2K. To account for internal temperature fluctuations, I have used the "Temperature difference between cutout and setpoint" approach, setting the temperature at -18°C and the cutout at 2K.

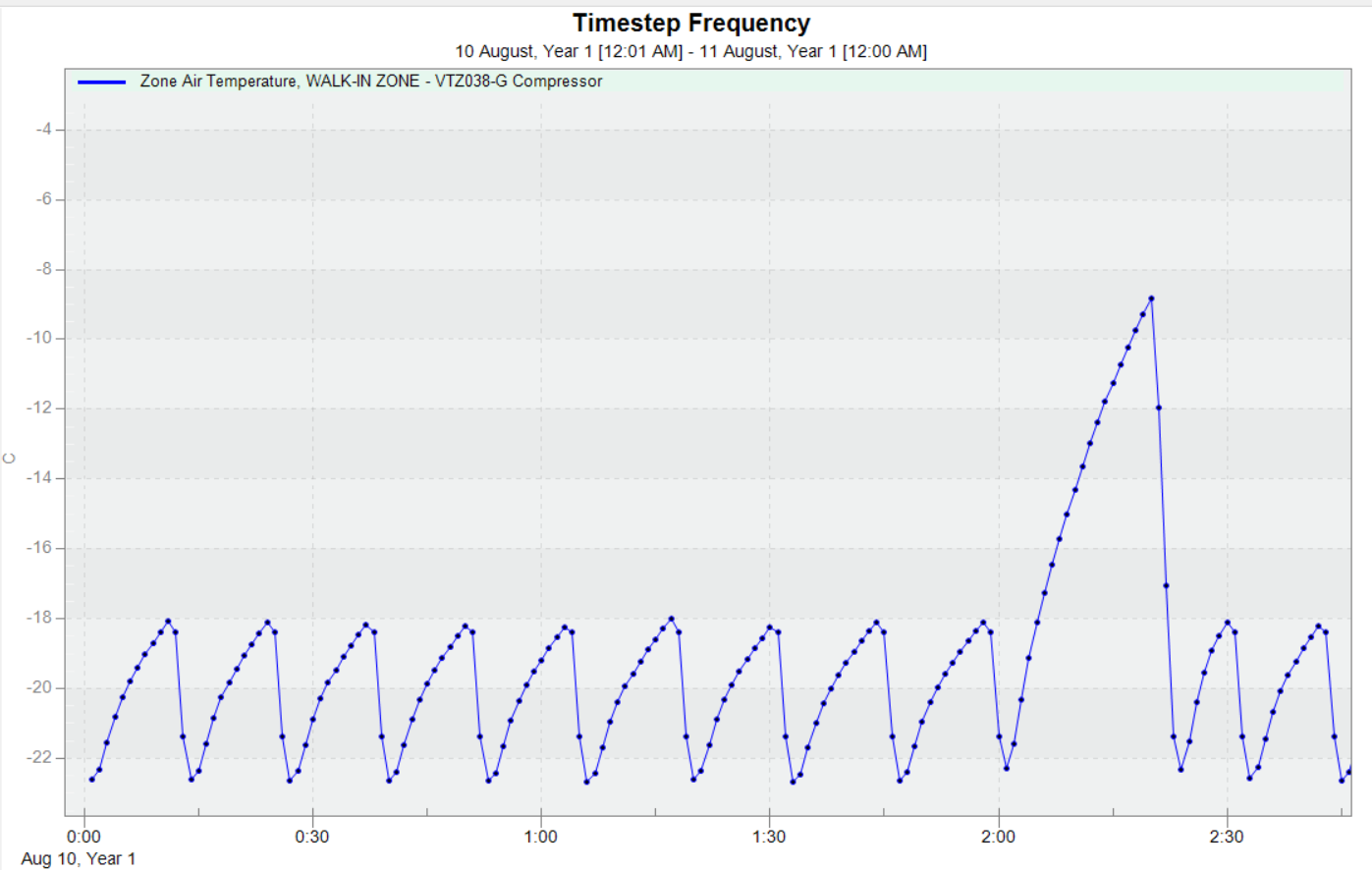

I run a simulaton and ploted the main zone air tempearature below. It can be seen that the temperature is indeed between -22 an d-18 °C as desired. However, the temperature fluctuation are too much, meaning that the compressor start and shuts many times (on/off 9 times in almost 2 hours). In adition the temperature decrease very quickly.

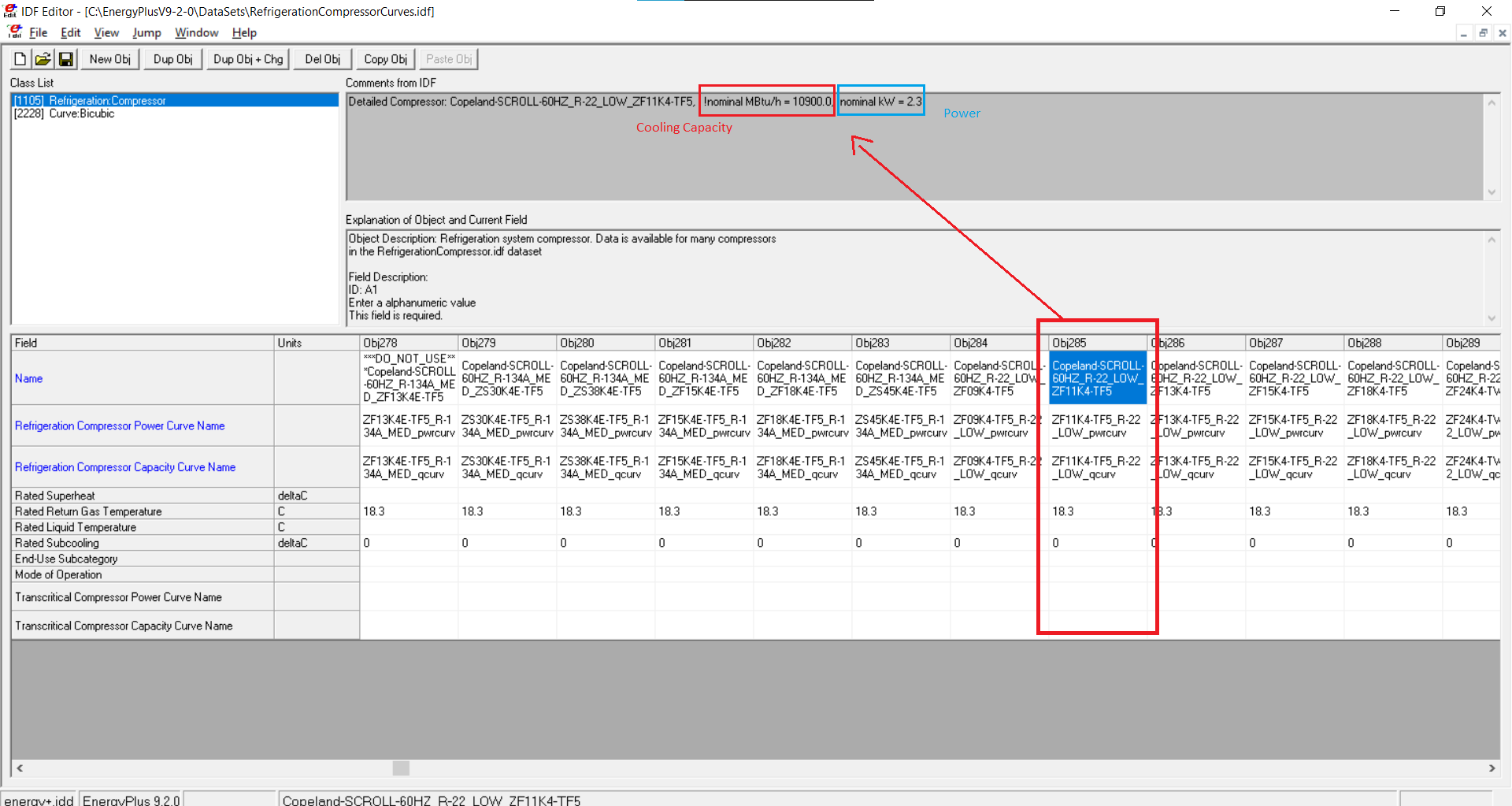

It must noted that I have used the compressor provided by E+ DataSet. So I have checked the cooling capacity of these compressors and foud that all of them are characterized with a high cooling capacities. In the model, I used the Copeland-SCROLL-60HZ_R-22_LOW_ZF11K4-TF5 which has a cooling capacity of 10900 MBtu/h approximately 3194474 kW, which is enormous (Fig. below).

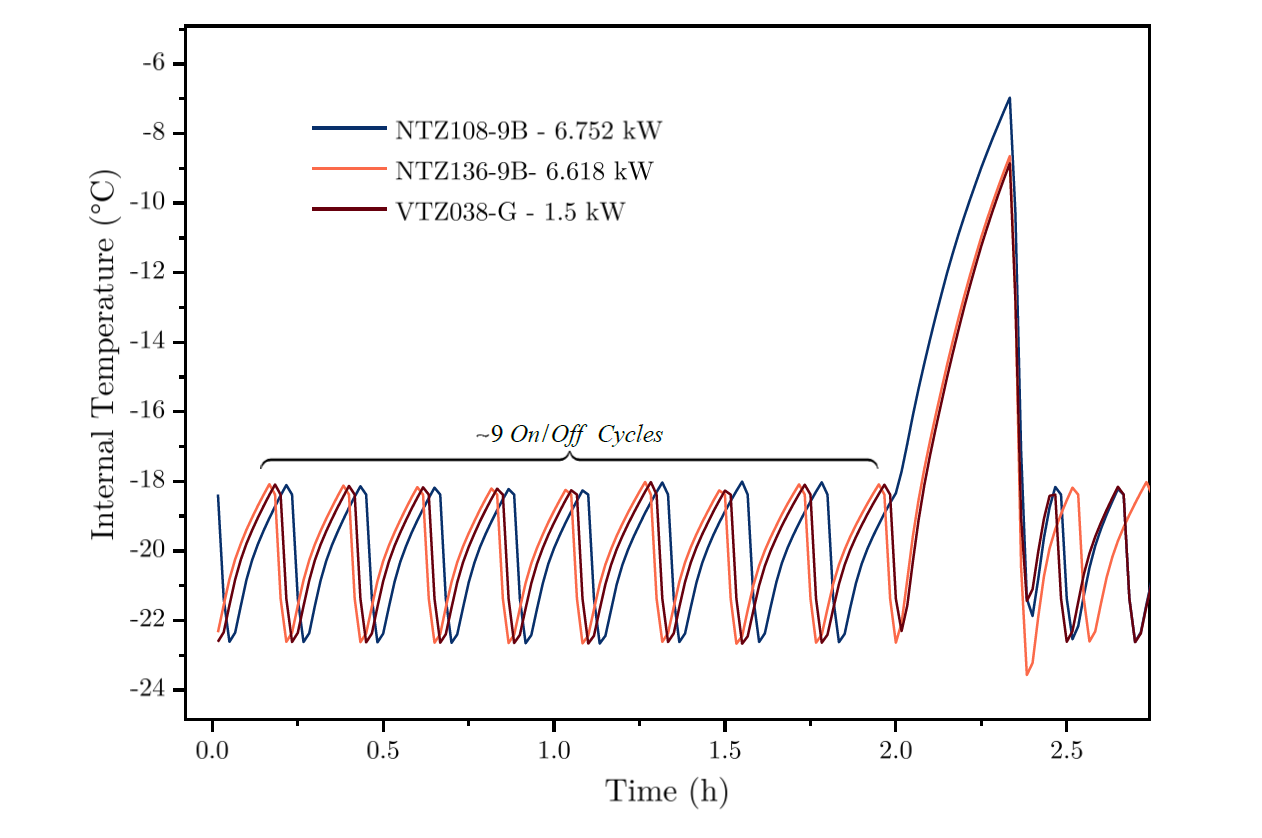

My next step was to geneate performance curves using the manufacturer's data for compressors that have a small cooling capacity. I performed a regression analysis in Excel to generate these curves. The data relating to the cooling capacity and energy consumption of the compressors studied were obtained from the Coolselector2 software, available at "www.danfoss.com/en/coolselector-2/".

In my analysis, I focused on three different compressors with different cooling capacities:

- NTZ108-9B – Cooling capacity : 6.752 kW

- NTZ136-9B- Cooling capacity : 6.618 kW

- VTZ038-G – Cooling capacity : 1.5 kW

After running simulations with these compressors, I observed the same temperature profiles as last time - lots of temperature fluctuations and a rapid drop in temperature.

Normally, the lower the cooling capacity, the slower the temperature drop and the longer the compressor's ON periodes.

If any one could explain why the compressor cooling capacity is not affecting the temperature drop?

I hope my post is clear.

Thank you.

Update

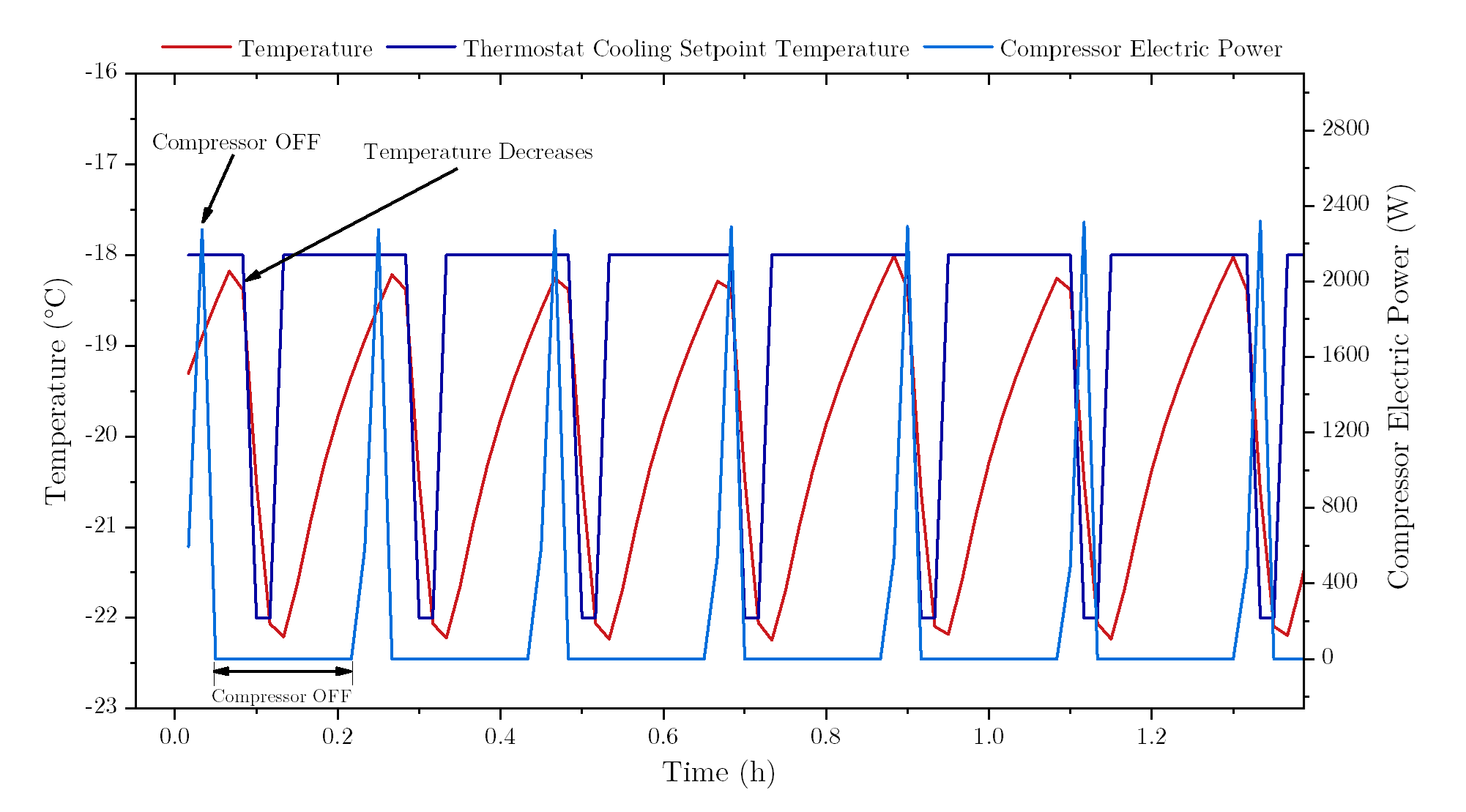

I'm currently working on pinpointing a bug in my model. To aid in the troubleshooting process, I've generated a plot illustrating the evolution of Zone Air Temperature and Compressor Electric Power, presented in the figure below.

As you can see that there's a period during which the compressor is shutdown, yet the Zone Air Temperature continues to decrease, which seems is not normal. Does anyone have any idea what is causing this problem?

Much appreciated.