aedg office hvac wshp doas - measure problems

Simulation community -

I'm having trouble using the "aedg office hvac wshp doas" measure. After creating a fairly simple model (5 zones, 5 stories) with pretty much all ASHRAE 90.1-2009 defaults, I attempted to use the aedg wshp whole building HVAC measure. It appears to work and specifies all of the equipment successfully, and even runs successfully, but my cooling unmet hours during occupied times are 4000+. Looking through the errors, it looks like these five are responsible:

* Warning * GetSpecificHeatGlycol: Temperature is out of range (too high) for fluid [WATER] specific heat * * ~~~ * ..Called From:CalcHPCoolingSimple:SourceSideInletTemp,Temperature=[228.47], supplied data range=[0.00,125.00] * ~~~ ** Environment=NEW ORLEANS LAKEFRONT AP ANN CLG .4% CONDNS DB=>MWB, at Simulation time=08/21 00:00 - 01:00

* Warning * GetDensityGlycol: Temperature is out of range (too high) for fluid [WATER] density * * ~~~ * ..Called From:FindCompSPLoad,Temperature=[234.74], supplied data range=[0.00,100.00] * ~~~ ** Environment=NEW ORLEANS LAKEFRONT AP ANN CLG .4% CONDNS DB=>MWB, at Simulation time=08/21 00:00 - 01:00

* Warning * CoolingTower:SingleSpeed "COOLING TOWER SINGLE SPEED 1" * ~~~ * Cooling tower water outlet temperature (-0.24 C) is below the specified minimum condenser loop temp of 1.00 C * ~~~ * Environment=RUN PERIOD 1, at Simulation time=01/02 16:00 - 17:00

* Warning * GetSpecificHeatGlycol: Temperature is out of range (too low) for fluid [WATER] specific heat supplied values * * ~~~ * ..Called From:PlantLoopSolver::UpdateAnyLoopDemandAlterations,Temperature=[-0.24], supplied data range=[0.00,125.00] * ~~~ ** Environment=RUN PERIOD 1, at Simulation time=01/02 16:00 - 17:00

* Warning * GetDensityGlycol: Temperature is out of range (too low) for fluid [WATER] density * * ~~~ * ..Called From:FindCompSPLoad,Temperature=[-0.24], supplied data range=[0.00,100.00] * ~~~ ** Environment=RUN PERIOD 1, at Simulation time=01/02 16:00 - 17:00

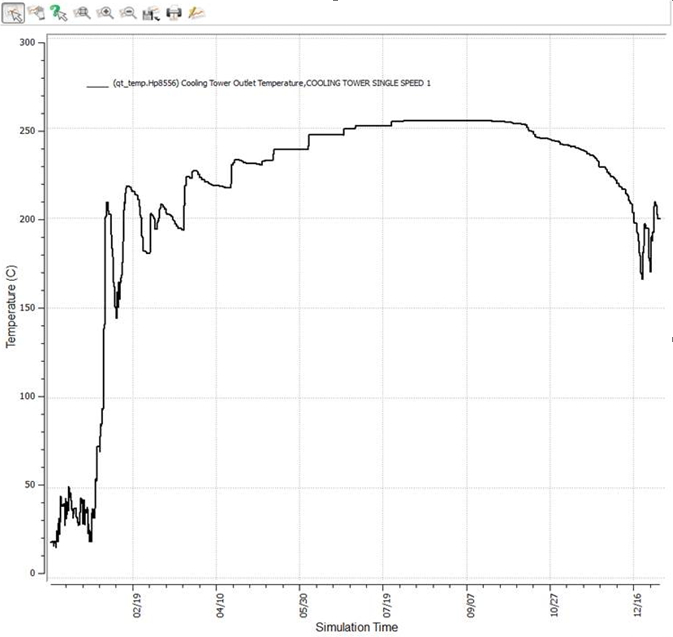

Upon looking at the cooling tower outlet temperature, see image below, it spikes in February and stays in the unreal 200 deg celsius range. I'm not sure what is causing this, and I've even tried it on a single zone, even simpler model, and I get the same error and results. So I'm not sure if its something on my part or if there is an issue with the script.

I've ran the "aedg office VHAC VAV with DX Cooling" and it works properly without any crazy temperature spikes or unmet hours.

Any help is greatly appreciated! Here is a link to a zipped folder with the osm and run files in case it's helpful.

https://drive.google.com/file/d/0B6aA...

Cheers,

-jake

ASHRAE 90.1-2007 or 2010?

Did you mean five zones per floor?