Severe Error: Found Material that is too thin and/or too highly conductive

The answer to my question is provided to some extent in this previous post, but I would like to know how everyone models radiant ceiling panels.

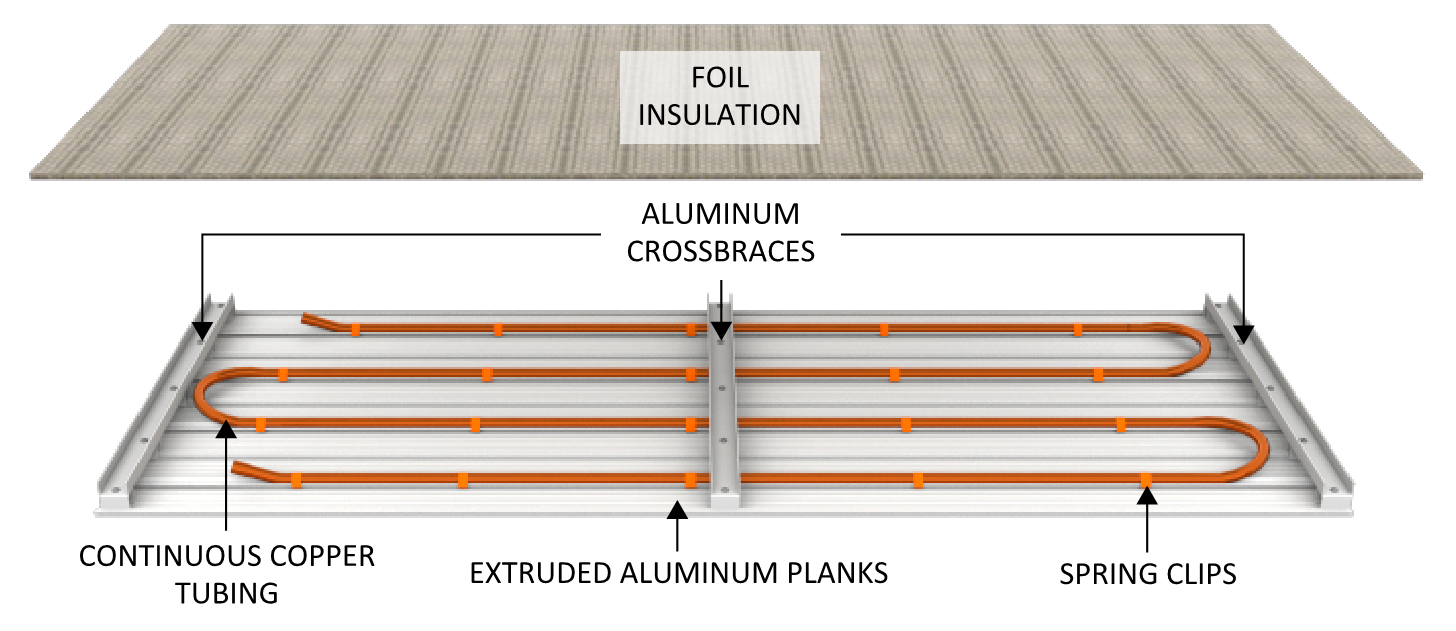

Radiant ceiling panels are usually made of thin aluminum. Chilled water pipes are on the thin alminum panel, and the insulation board is on the chilled water pipes.

I modelled radiant ceiling panels as follows. The thickness of the aluminum panel is 0.002m (2mm).

Construction,

INTERIOR CEILING with Radiant, !- Name

Concrete 150mm, !- Outside Layer

Ceiling air space resistance, !- Layer 2

Polystyrene foam 50mm, !- Layer 3

Aluminum Radiant Panel; !- Layer 4

ConstructionProperty:InternalHeatSource,

Floor Source INTERIOR CEILING, !- Name

INTERIOR CEILING with Radiant, !- Construction Name

3, !- Thermal Source Present After Layer Number

3, !- Temperature Calculation Requested After Layer Number

1, !- Dimensions for the CTF Calculation

0.1, !- Tube Spacing {m}

0; !- Two-Dimensional Temperature Calculation Position {dimensionless}

Material,

Aluminum Radiant Panel, !- Name

MediumSmooth, !- Roughness

0.002, !- Thickness {m}

210, !- Conductivity {W/m-K}

2700, !- Density {kg/m3}

880, !- Specific Heat {J/kg-K}

0.9, !- Thermal Absorptance

0.7, !- Solar Absorptance

0.7; !- Visible Absorptance

Material,

Concrete 150mm, !- Name

MediumRough, !- Roughness

0.15, !- Thickness {m}

1.74, !- Conductivity {W/m-K}

2240, !- Density {kg/m3}

900, !- Specific Heat {J/kg-K}

0.9, !- Thermal Absorptance

0.7, !- Solar Absorptance

0.7; !- Visible Absorptance

Material,

Polystyrene foam 50mm, !- Name

MediumRough, !- Roughness

0.05, !- Thickness {m}

0.036, !- Conductivity {W/m-K}

43, !- Density {kg/m3}

1210, !- Specific Heat {J/kg-K}

0.9, !- Thermal Absorptance

0.7, !- Solar Absorptance

0.7; !- Visible Absorptance

Material:AirGap,

Ceiling air space resistance, !- Name

0.18; !- Thermal Resistance {m2-K/W}

I got the following severe error.

** Severe ** InitConductionTransferFunctions: Found Material that is too thin and/or too highly conductive, material name = ALUMINUM RADIANT PANEL

** ~~~ ** High conductivity Material layers are not well supported for internal source constructions, material conductivity = 210.000 [W/m-K]

** ~~~ ** Material thermal diffusivity = 8.838E-005 [m2/s]

** ~~~ ** Material with this thermal diffusivity should have thickness > 0.39886 [m]

** ~~~ ** Material may be too thin to be modeled well, thickness = 2.00000E-003 [m]

** ~~~ ** Material with this thermal diffusivity should have thickness > 3.00000E-003 [m]

The simulation completed successfully. Can I ignore the severe error? Or should I follow the severe error message and change the thickness of alminum panel to 0.4m? 0.4m thick aluminum panels are unrealistic. Changing the thickness naturally changes the energy consumption. The high conductivity of the aluminium panel is also important for radiant cooling and should not be reduced. How does everyone model the radiant ceiling panels i.e. as per reality or considering EnergyPlus characteristics?

The idf files (V22-2-0) are here for reference.

Hey Keigo. No answers, just an observation. Changing panel thickness from 2mm to e.g. 5mm takes care of the "2mm vs 3mm (min)" part of the error message. Reducing panel conductivity to 20 instead of 210 takes care of the "thermal diffusivity" part of the message. This generates a 0.3% decrease in annual kWh. Significant? Depends. Other parameters could be as significant, e.g. surface convection choices.

0.3% is not so significant.

Do you prefer changing material properties to take care of the error messages rather than inputing the actual material properties?

At a minimum, I'd keep a comment/note in the IDF (in case a reviewer asks about the error ... you can easily switch back). Otherwise, it's hard to say without knowing more about the context/project. Other modelling choices may represent even greater uncertainties, e.g. 100% (vs 75% or 50%) ceiling coverage? explicit modelling of plenums (or dead air spaces) under the roof construction? These may be more significant.

I see. Thank you for your comments.

Hello. May I know how you solved that problem? I am also having this error in my model.