Setting up a DOAS with a Floating Supply Temp

What's the best way to set up a DOAS in OpenStudio with a floating (deadband) supply temperature that supplies air between 60F and 75F with the heating and cooling coil not operating between these temperatures? I believe that the dual deadband is for just waterside equipment, right? I was thinking the simplest way would to have a scheduled setpoint manager of 60F after the heating coil and 75F after the DX coil, but this has the problem of not accounting for the fan heat. Moreover, with an ERV is how would you control it to temper the air when outside of the limits, but bypass otherwise?

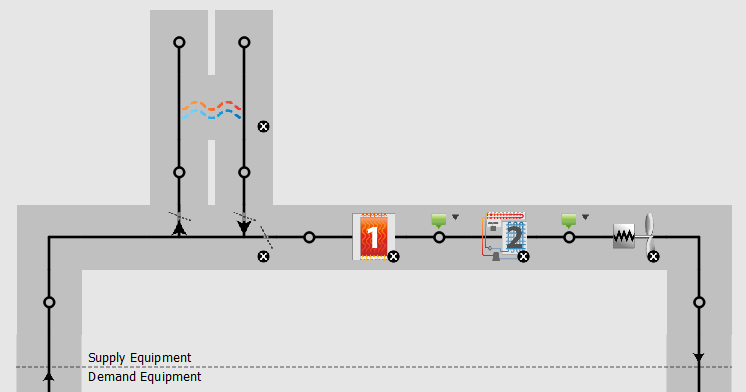

Solution Using a Work Around

I would first read the discussion with @Kyle Benne in the comments of his answer to understand how we got here. Seeing as the SetpointManagerScheduledDualSetpoint object is averaging the high and low setpoint I decided to use a slight workaround. My initial take was to have a SetpointManager:Scheduled after the furnace and cooling coil set at 55F and 75F respectively with the ERV and mixed air node using a SetpointManager:MixedAir object to reference the SetpointManager just after the furnace because the model is in a predominantly cooling environment and I don't want to unnecessarily overheat the air. I then ended up shifting the SetpointManager:Scheduled object on the cooling coil to the node after the fan and added SetpointManager:MixedAir object at the cooling coil to reference the setpoint after the fan. I did this because I wanted to supply room neutral air when cooling rather than slightly warm air. I wasn't too worried about the fan heat provided when tempering the air.

Oh thats sorta sweet. And such a hack! We're adding duct so I guess that will make this 1% less of a hack. I feel like your second paragraph should be converted to an answer and I should remove my answer. The new answer should highlight what we discussed in the comments about how dual setpoint behaves on air system and why the hack is necessary.

I've posted a final answer below. I would probably keep your initial answer because the conversation in the comments may be useful for others.