Cooling coil sizing difference

- I am doing a cooling load calculations and coil selection for a single zone project.

- DDY conditions were imported in the site tab.

- In simulation tab/ Simulation control/ Do HVAC simulation for sizing periods was and Run simulation for sizing periods is ON and Run simulation for weather file run periods is OFF.

- Cooling coil total cooling rate and Cooling coil sensible cooling rate were set to ON in the OUTPUT variables tab

Results:

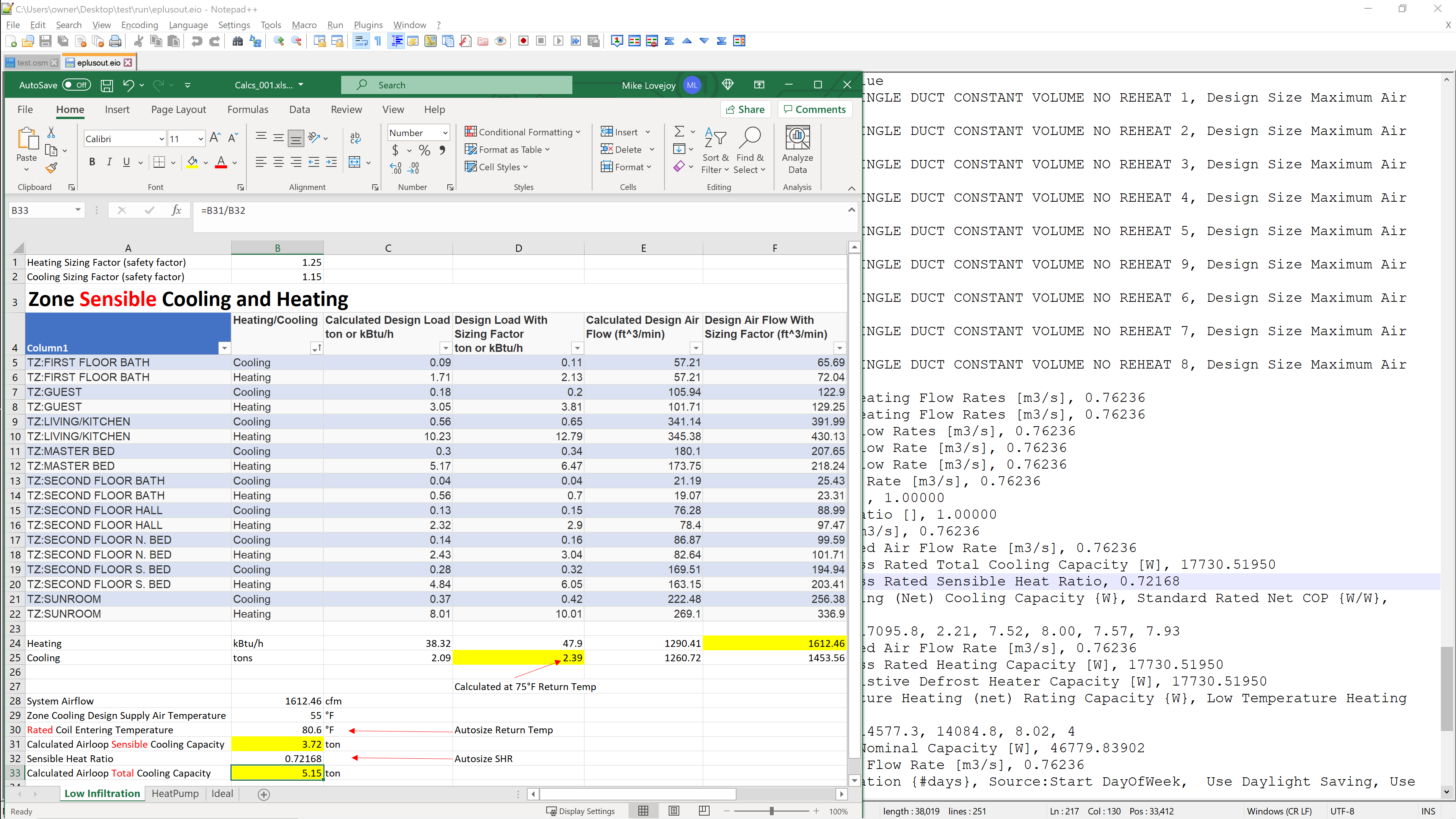

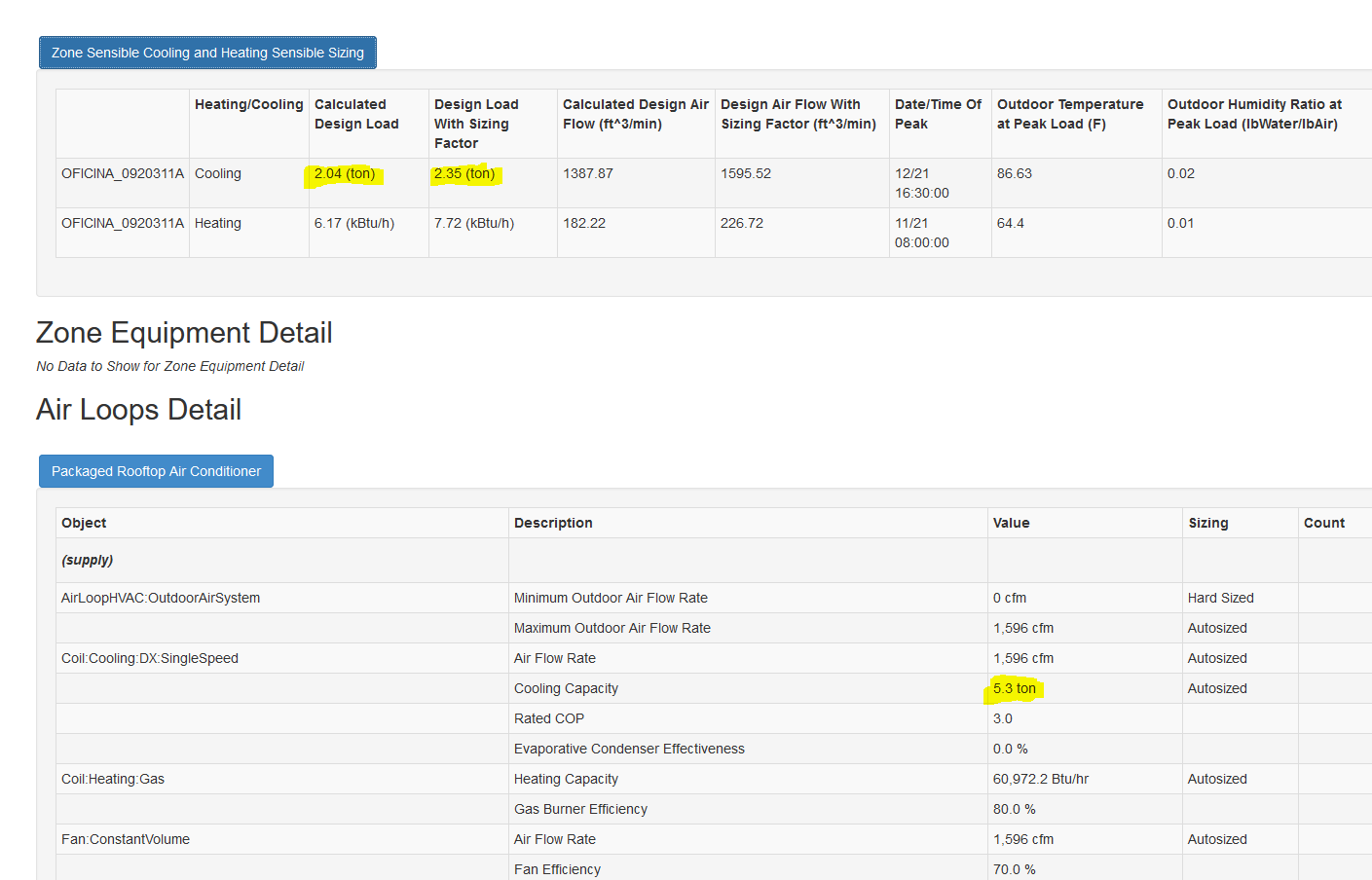

In the Openstudio result: Zone sensible cooling and heating sensible sizing: Cooling: Calculated design load: 2.04 Ton and Calculated design load with sizing factor: 2.35 Ton

In the air loops detail results the cooling coil cooling capacity is 5.3 Ton

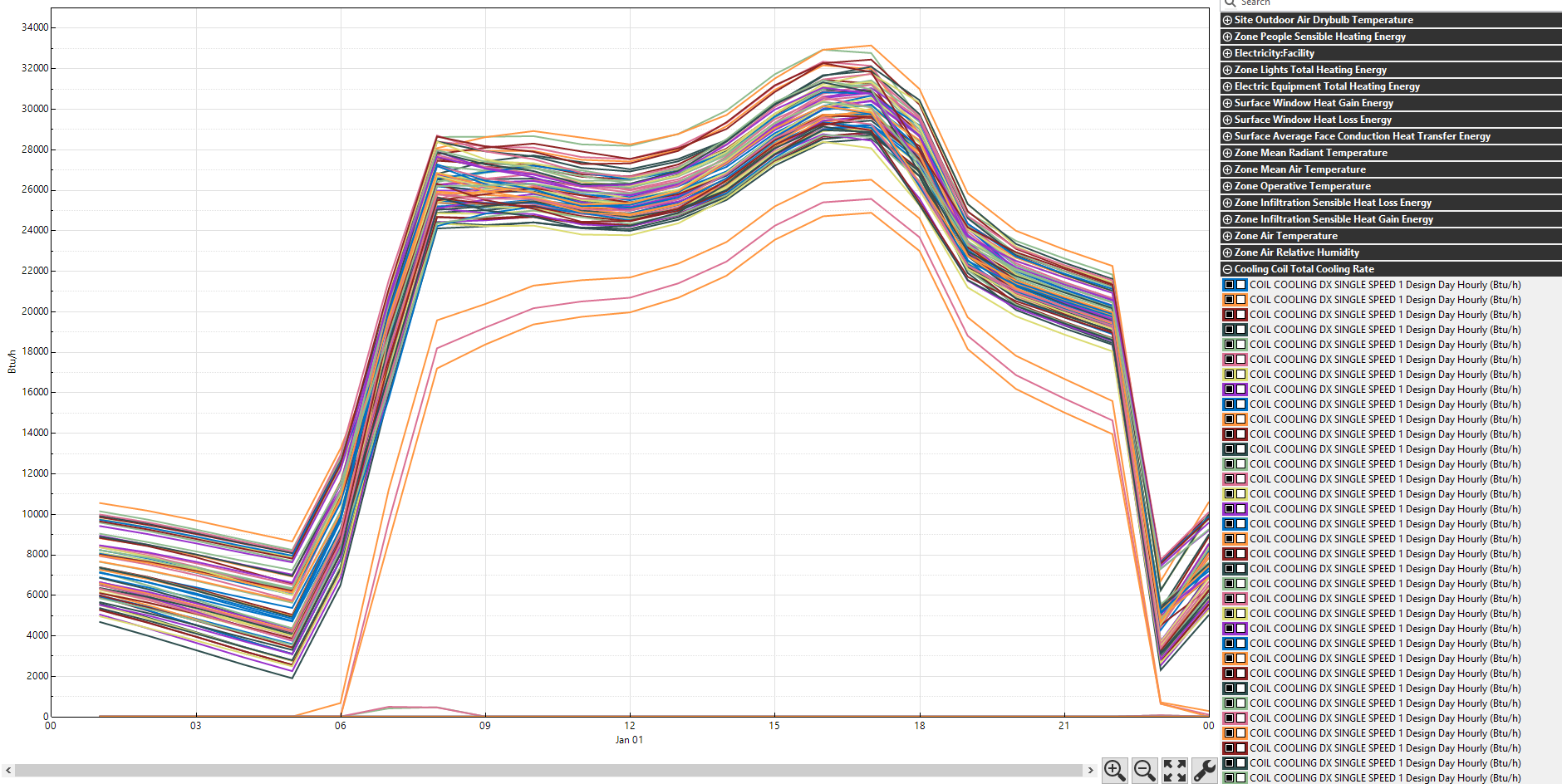

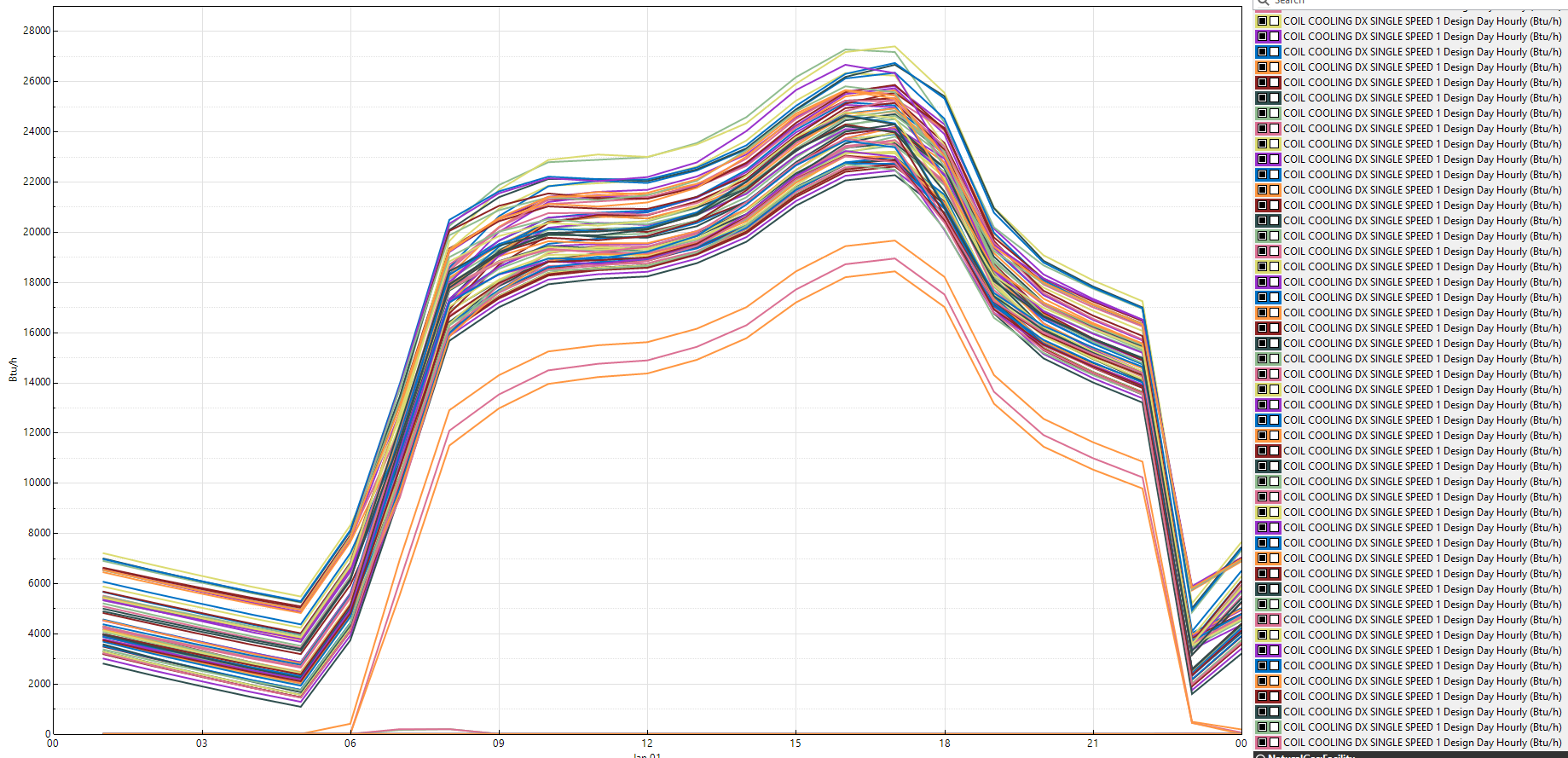

In the Output variable: Cooling coil total cooling rate the highest value for all the design days is 33000 BTU/h (2.75 Tons).

- In the Output Variable: Cooling coil sensible cooling rate the highest value for all de design days is 27500 BTU/h (2.3 Tons).

Is there anything that I am doing wrong or missing?

I don’t understand why the cooling coil capacity from the air loop detail (second pic) is 5.3 Tons. it shouldn’t be something about 2.75 tons (Cooling coil total cooling capacity maximum value from the output variable).

Any help will be appreciated.