High Pump Energy Consumption

Greetings,

I've defined 1 indirect absorption chiller loop and 1 condenser loop in my Openstudio model and I have configured it to be running in the summer for cold water to be provided to cooling coils.

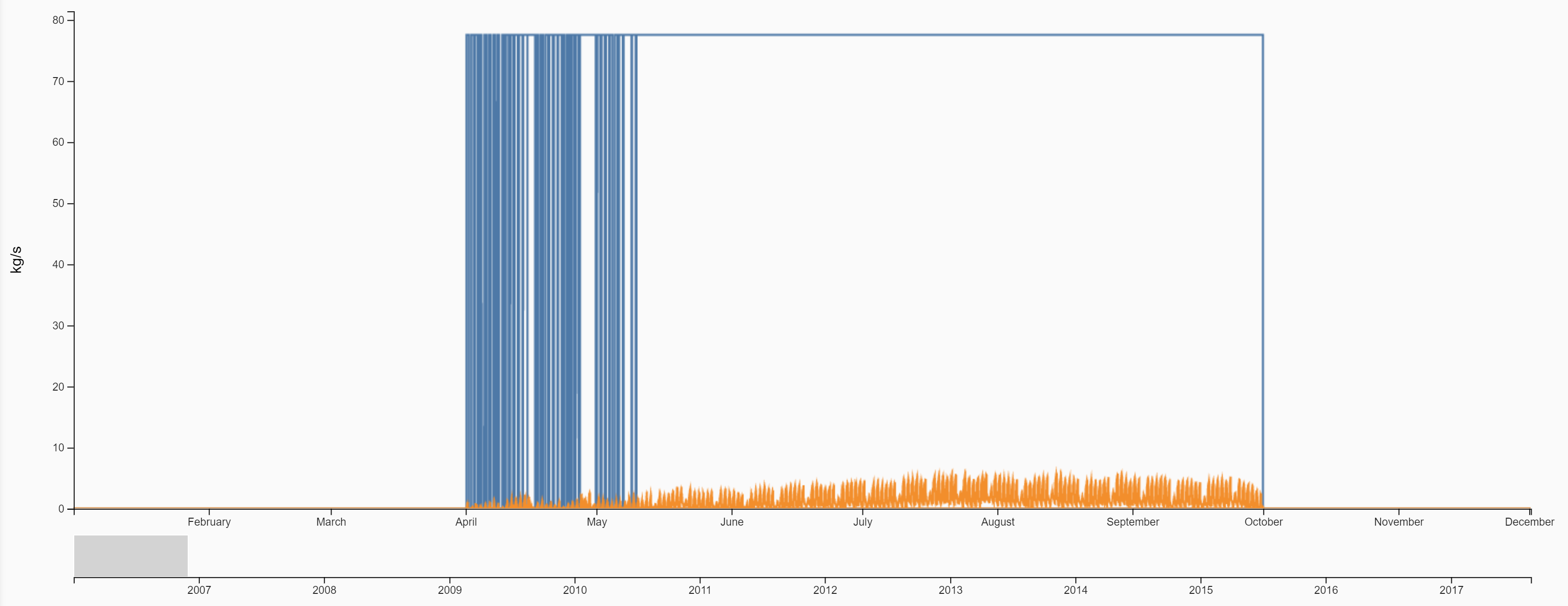

When simulating my model, I am getting high pumps energy consumption during this period, which seem unreasonable. A plot of the mass flow rates for the chiller and condenser pumps is shown below:

There seems to be very high values for the condenser pump (about 80 kg/s) compared to the chiller pump (about 4-6 kg/s). Both are Variable Speed Pumps and working intermittent.

Could anyone assist me to solve this issue of high pumps energy consumption ? I can provide my model files if needed upon request.

Thank you.

Hi Ahmad, are you autosizing the design condenser flow for the chiller? If so, you should take a look at your EIO file and see if it's autosizing to 80 kg/s. The chiller is going to request its full design condenser flow when it is on, regardless of pump type, so that may be what you're running into here.

Hi Cody, thanks for the reply. Yes, I am auto-sizing.

I took a look at the EIO file and here is what is inside:

"Design Size Design Condenser Water Flow Rate [m3/s], 7.75550E-002 CONDENSER WATER LOOP, Maximum Loop Flow Rate [m3/s], 7.75550E-002

CHILLED WATER LOOP, Maximum Loop Flow Rate [m3/s], 2.23400E-002 Design Size Design Chilled Water Flow Rate [m3/s], 2.23400E-002"

Seems I am running as you are suggesting. Please give me your thoughts on how to solve this issue.

Many thanks !

Got it! So is the main problem that the flow is much higher than you expect, or that you expect it to operate with variable flow? Or is the flow reasonable and your concern is that the pump power is sizing too high?

The basic idea started from results showing high pump power consumption throughout the summer period which should be from cooling. Then after plotting the flow, it showed higher than expected. I would be grateful to prioritize solving the issue of high power consumption since my end work is related to energy consumption.