Solving Plant temperatures are getting far too hot

Hello,

Good day to all.

I am modeling an HVAC system for an offices building with 8 floors which has several AHUs and FCUs installed. The simulation stops with the following error (Copied as is):

** Severe ** Plant temperatures are getting far too hot, check controls and relative loads and capacities

** ~~~ ** PlantLoop Name (DemandSide)= HOT WATER LOOP

** ~~~ ** PlantLoop Setpoint Temperature=67.0 {C}

** ~~~ ** PlantLoop Inlet Node (SupplySide) does not have a Setpoint.

** ~~~ ** PlantLoop Inlet Node (DemandSide) does not have a Setpoint.

** ~~~ ** PlantLoop Outlet Node (SupplySide) has a Setpoint.

** ~~~ ** PlantLoop Outlet Node (DemandSide) does not have a Setpoint.

** ~~~ ** PlantLoop Outlet Node (DemandSide) "NODE 134" has temperature=300.1 {C}

** ~~~ ** PlantLoop Inlet Node (DemandSide) "NODE 133" has temperature=300.2 {C}

** ~~~ ** PlantLoop Minimum Temperature=0.0 {C}

** ~~~ ** PlantLoop Maximum Temperature=100.0 {C}

** ~~~ ** PlantLoop Flow Request (SupplySide)=6.9 {kg/s}

** ~~~ ** PlantLoop Flow Request (DemandSide)=0.6 {kg/s}

** ~~~ ** PlantLoop Node (DemandSide) "NODE 134" has mass flow rate =0.6 {kg/s}

** ~~~ ** PlantLoop PumpHeat (SupplySide)=1982.2 {W}

** ~~~ ** PlantLoop PumpHeat (DemandSide)=185.5 {W}

** ~~~ ** PlantLoop Cooling Demand=6855817.6 {W}

** ~~~ ** PlantLoop Heating Demand=0.0 {W}

** ~~~ ** PlantLoop Demand not Dispatched=0.0 {W}

** ~~~ ** PlantLoop Unmet Demand=-6855817.6 {W}

** ~~~ ** PlantLoop Capacity=411062.5 {W}

** ~~~ ** PlantLoop Capacity (SupplySide)=411062.5 {W}

** ~~~ ** PlantLoop Capacity (DemandSide)=0.0 {W}

** ~~~ ** PlantLoop Operation Scheme=HOT WATER LOOP OPERATION SCHEMES

** ~~~ ** PlantLoop Operation Dispatched Load = 0.0 {W}

** ~~~ ** PlantLoop Operation Dispatched Load (SupplySide)= 0.0 {W}

** ~~~ ** PlantLoop Operation Dispatched Load (DemandSide)= 0.0 {W}

I read the other posts asking questions related to what I am asking too but I wasn't able to locate the problem.

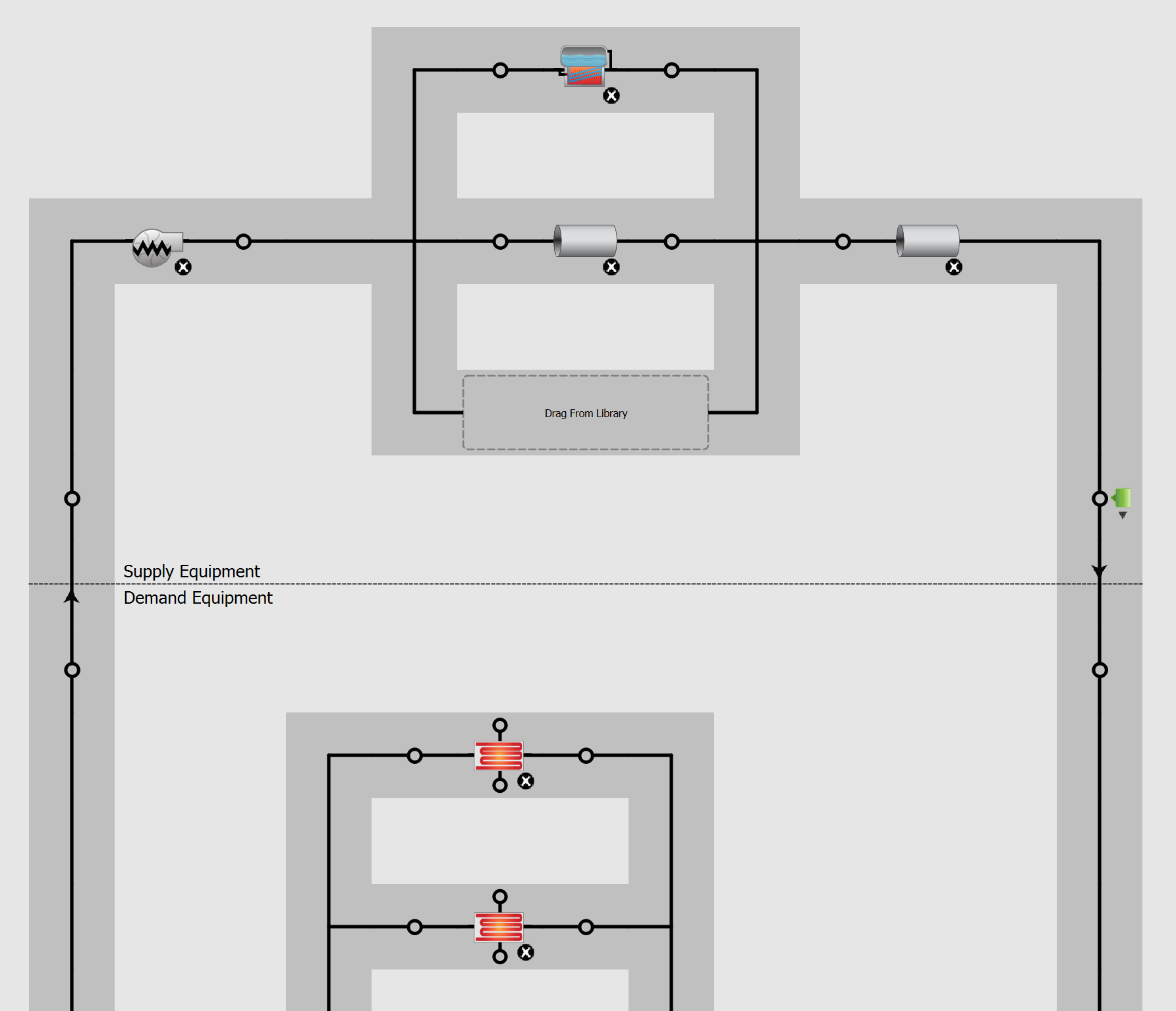

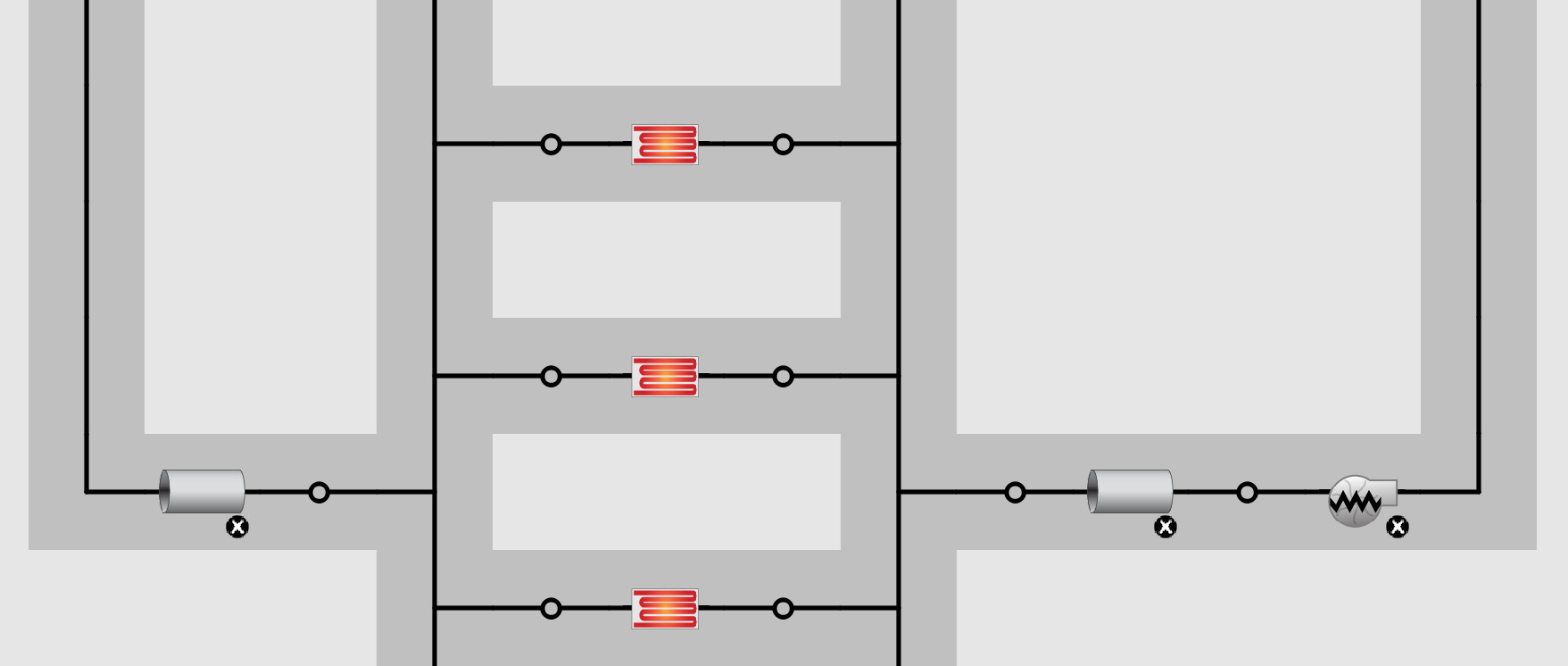

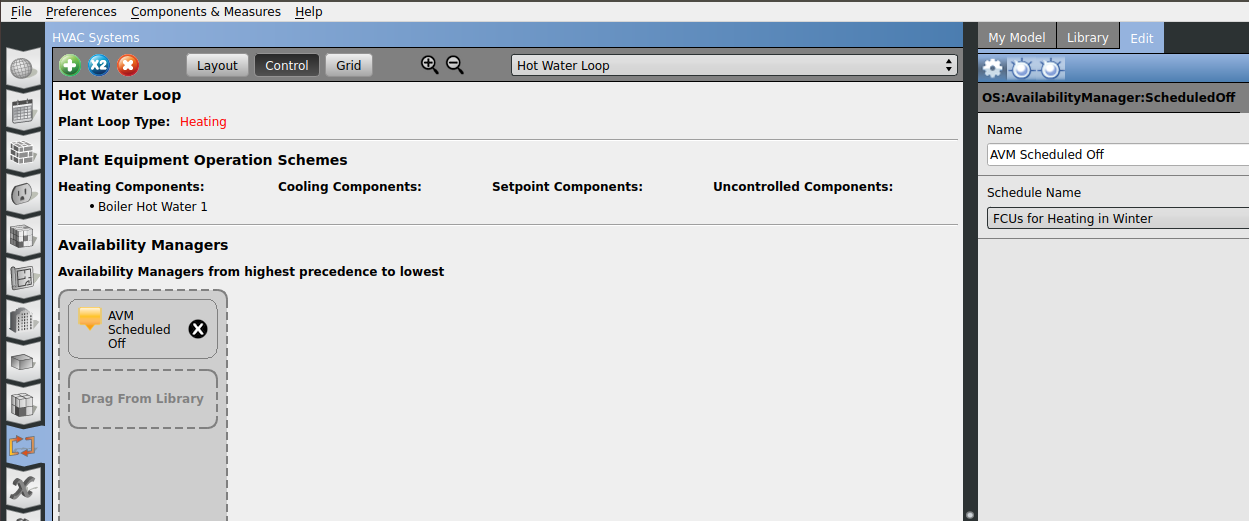

The following are photos for the supply/demand of the loop (There are a lot of heating coils so I took two screenshots showing the essentials):

The outlet node supply side set point is set to 80 C. The pumps are intermittent. Both AHUs and FCUs coils inlet water temperatures are set to 80 C and outlet water temperatures to 69 C. The AHUs coils capacities range between 5 kw to 10 kw (I have about 11 coils for the AHUs). The boiler design flow rate is auto-sized. The plant design loop exit temperature is 80 C and loop design temperature difference is 11 C.

I can't seem to solve my problem. Can you assist ?

Many thanks in advance.

Why do you have a pump on the demand inlet branch?

There are two hot water pumps in the building, one primary and the second secondary. I added a pump in the demand side and used the common pipe option for the loop

I just removed it and left only the supply branch one and I still have the same problem

I would recommend to stay away from Common Pipe option, and instead use two PlantLoops connected by a HeatExchanger:FluidToFluid. You can find more info In the example 3 of Plant Application Guide: https://bigladdersoftware.com/epx/doc...

Your eplusout.err message seems to indicate there is a need for a (lot of) cooling on your demand side, not sure what's causing this for the limited amount of info I have.