Pumping system / Plant Convergence issue

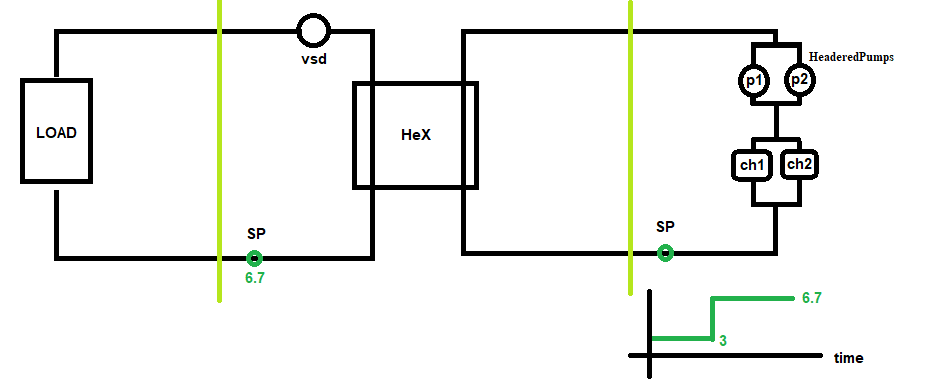

The following configuration of cooling loops in energyplus works with just a few of warnings which I will mention (coolingload operation control and two setpoints and HX hasoperationschememodulated control):

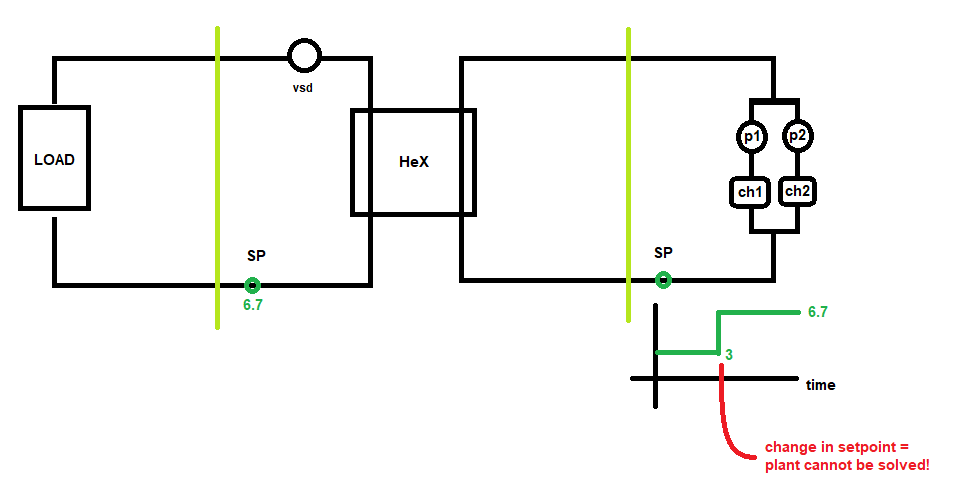

Now I want my pumps and chillers to have different sizes, but HeaderedPumps:ConstantSpeed gives identical pumps, so I decided to go with the following configuration with Pump:ConstantSpeed (only change):

I got plenty of these warnings, in one-day simulation, at the time that setpoint rises from 3 to 6.7:

************* ** Warning ** HeatExchanger:FluidToFluid named HX - Iteration Limit exceeded calculating demand side loop flow rate continues.

************* ** ~~~ ** This error occurred 29 total times;

************* ** ~~~ ** during Warmup 0 times;

************* ** ~~~ ** during Sizing 0 times.

************* ** ~~~ ** Max=74.812813 Min=0.616959

It seems that when the setpoint goes from 3 to 6.7, plant has fluid in supply side with temperature lower than new setpoint (6.7). So it stops working while Heatexchanger is demanding load. I don't know if it's a bug or is something I'm doing wrong. I will be grateful for any suggestion to resolve this issue.

Update: I'm trying an EMS (python) solution like below but it doesn't work:

If demand>0 & PLR1==0 & PLR2==0:

pump1 (actuator) = ON

pump2 (actuator)= ON

pump1 flow (actuator)= max (internal variable)

pump2 flow (actuator)= max (internal variable)

The conditions are right but pumps flow does not change. I don't no why!

First, This is a great question. The schematics are most appreciated!

Could you try using a setpoint schedule that ramps up/down instead of abrutly going from 3 to 6.7 and vice versa? That is, do the transition in several steps over the course of an hour for example, where every Timestep you change it out a bit.

If your Timestep = 4 (15min), That would be H = 3, (H+15min)=3.925, (H+30min)=4.85, (H+45min)=5.775, (H+1hr)=6.7

@Julien Marrec, Thank you. I tried ramping down the setpoint but that couldn't help. Here is a detailed output variable report of the simulation. Condition met column refers to the condition in the EMS code which I mentioned in my question. I should mention that the supply load of the primary and secondary are not equal! Maybe because of chillers' false loading...