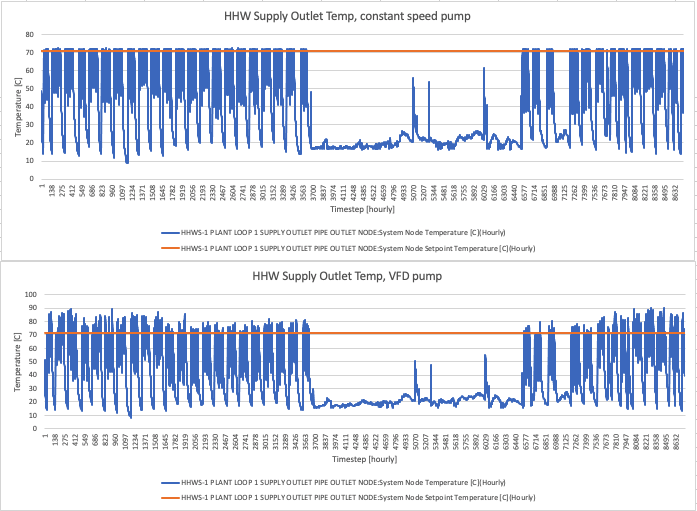

HW loop not making setpoint after switching to VFD pump

This problem is occurring in v8.7. For a model with a hot water loop serving VAV:reheats throughout a building, setpoint is met as expected using a constant speed pump with intermittent control where a large majority of the flow is going to bypass. When I switch to a VFD pump, using the same design parameters, the loop stops making setpoint and boiler energy use increases significantly. Has anybody dealt with this issue before, or can anyone provide some insight on where I should be looking for incompatibilities? Thanks!

Things I've tried so far with no change in results:

Baseline model is using a gas boiler on the "NotModulated" setting. I tried both NotModulated and "LeavingSetpointModulated" forcing the same setpoint at the boiler as with the loop setpoint manager.

Changing the VFD pump from intermittent control to continuous.

Using the headered VFD pump object with just one pump in the bank and identical design parameters.

With the VFD pump, no flow is going to bypass, but I still tried a run with both supply and demand bypass disabled.

Move pump from boiler branch out to main loop (HHWS-1:Supply)

Comparison of results:

i would be interested to see the supply AND return water temperature so i can see the DeltaT load on the boiler. I usually set my boiler design for 30 degrees F delta control. Condensing boilers want to see a large temperature drop.

The design dT for this particular boiler is 20 F, which is being specified in the sizing plant and heating coil tables. For the baseline scenario with constant speed pump, the operational dT is very small, ~2 F average, due to the high flow (10.9 kg/s). In the VFD pump scenario, all design parameters identical, the operational dT is more like ~40 F on average, as the flow is much lower at ~0.75 kg/s on average.

Is your bypass controlled by temperature or pressure?

I'm almost 100% positive that the (pipe:adiabatic) bypass is controlled by demand.

so are you comparing a 100:1 turndown modulating bypass valve to a 5:1 turndown boiler? They aren't going to control the same.