Equipment not sizing

I am using the DOE prototype large office model (A90.1 2013) and changing just the glass alone to understand the HVAC sizing and energy impact with switching to different glass types. I see that the equipment sizes especially the Chiller and the cooling tower remains the same. Maybe am I missing something? or since the prototype model has a data center in the basement floor, glazing is having no impact?

Why is there no savings (HVAC) even when compared to a single pane glass? I have attached the E+ files(V8.9) for your reference- https://drive.google.com/drive/folder...

Thanks

Are you autosizing the chiller? The chiller and cooling tower get hard-sized when the prototype measure runs.

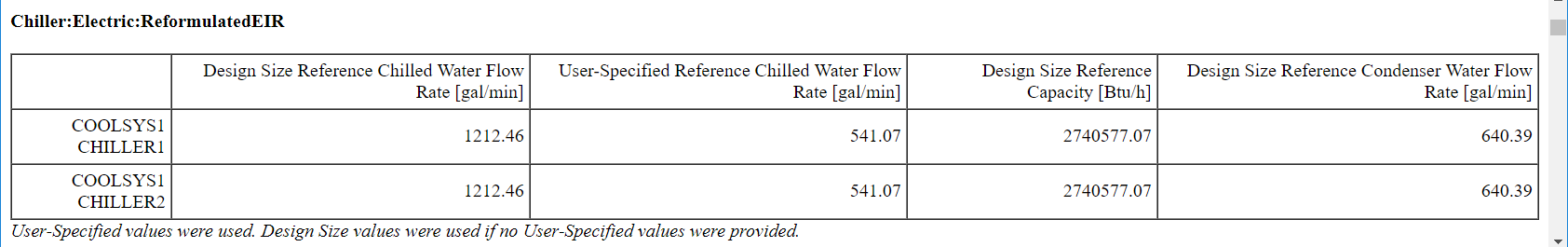

@mdahlhausen Yes, I am autosizing the chiller, boiler cooling tower,etc. I changed all hard-sized components to autosize, still no savings. ANy thoughts?

I'd suggest: - check to make sure new glass type is implemented in the model in through the EnergyPlus report - check design days and sizing criteria, and which design day is dictating the size - check that the cooling loads are changing in a space with the new windows (add output variable and view timeseries output)

@mdahlhausen Thanks for your reply. I have checked the glass type and did play around with the SHGC and Tvis values, I see a change in the cooling coils and boiler. But still no change in the Chillers or the cooling tower. Probably glazing load not having any impact on the chillers or cooling tower??