"Full-load", "Load" and "Part-load" can be a confusing when referring to chillers as the term gets used for evaporator cooling load, condenser heat rejection load and compressor load (aka input power).

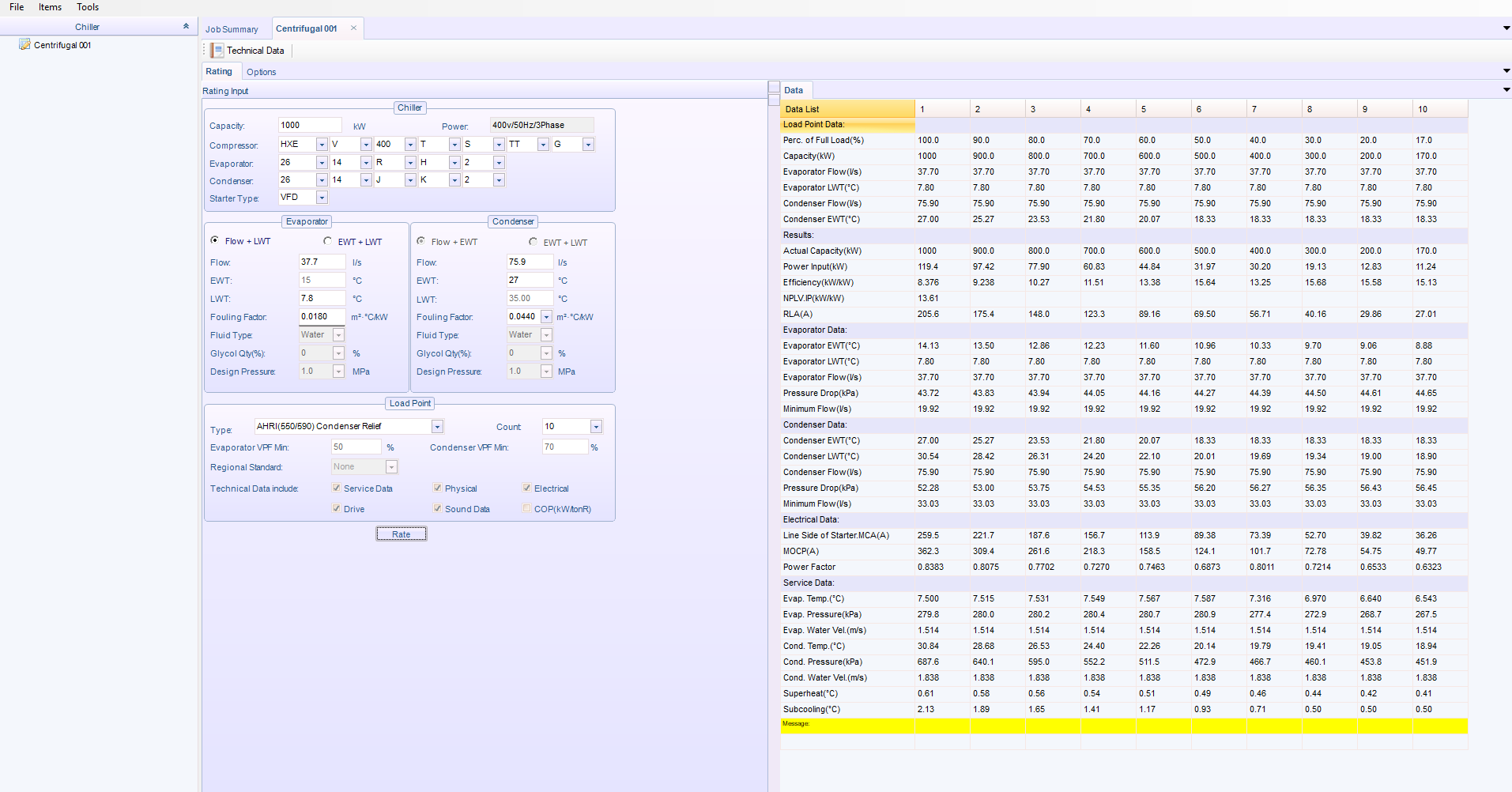

What we really want to know is the evaporator load (aka "capacity" or the evaporator flow rate and water delta T) at a fixed compressor load (compressor at 60 Hz or full speed) while holding flow constant (as you have shown in the selection software screenshot).

Most of the manufacturers representative's selection software is not set-up well to output this information as they very rarely would want to run a compressor full speed at low lift conditions if they can avoid it. In practice, running a compressor at full speed during low lift conditions can cause instability in the chiller operation and as a result the manufacturer may limit selections at those conditions or not have useful test data (hence note #2 in the bid form about stable operation). The compressor loading is primarily a function of lift (approximately by leaving condenser and evaporator temperatures) to manage refrigerant pressure in the evaporator and condenser while the output capacity (evaporator cooling load) is primarily a function of refrigerant mass flow rate. In a centrifugal chiller with a variable speed compressor the refrigerant flow is typically controlled by inlet guide vanes mostly independent of the compressor. As a result, in modern centrifugal chillers the available evaporator capacity may change very little across varying lift conditions because the inlet guide vanes may be limiting the refrigerant mass flow by design to keep the compressor lift low (and reduce speed/power consumption) although the exact control may vary based on manufacturer. Some manufacturers have an easier time producing this information particularly if the run low pressure machines that are more tolerant of a wider range of low lift operating conditions (like York and Trane centrifugal machines currently do).

The chiller EIR model curves do not capture a lot of these intricacies of modern chillers very well particularly for machines with multiple compressors or variable speed compressors. For single-compressor constant speed machines this data is much more straight-forward to test for and build a model around.

You may try asking for the selection at a constant input power at the various leaving condenser and evaporator water temperatures and then calculate the resulting capacity from the evaporator temperature differential. This can result in a lot of guess and check selections that the sales representative may not want to perform. The factory may have that information more readily available even if not officially published in the selection software for their representatives.

I just got the data from a JCI/York rep! The first person at any chiller manufacturer to actually find it and give me what I need.

This is interesting because I have successfully gotten Daikin, Trane, and York to fill out the Taylor Chiller bid form. Makes me wonder if they faked some of the numbers to fill out the form. I have not had success using the new one IES created. There seems to be a bug somewhere.

These seem to answer my question... the answer is, yes, I'm not crazy and the manufacturers should have this data. So keep trying. Thanks @crduggin and @bbrannon4. Post your comments as an answer, please!

Done. I can provide a good contact for getting Daikin chiller performance if you are interested.

Thanks for the great question, Anna. We are constantly running into this issue as well. Just wanted to update the Taylor bid form link, as the original link is broken.

Updated Bid Form Link