Heating curve (weather compensation) in OpenStudio / EnergyPlus?

Is it possible to create a heating setpoint in Energyplus that is dependent on outside temperature?

I would like to model a baseboard heater system with an inlet temperature that is dependent on outside conditions. For higher outside temperatures, less heating capacity is needed. This means lower supply temperatures can be sufficient to meet heating demand.

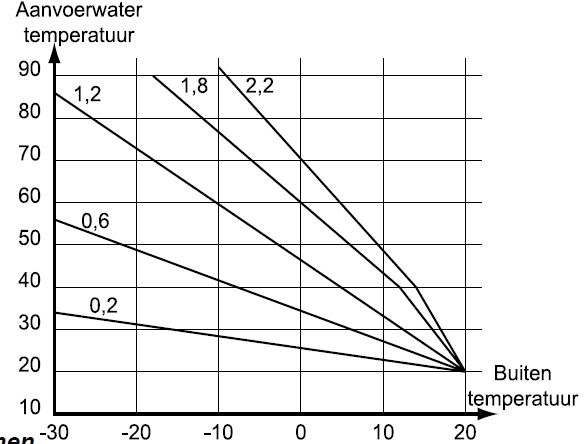

Typically a curve would look like this. (inlet temperature vs. outdoor air)

I have found SetpointManager:FollowOutdoorAirTemperature object, but that only follow the outdoor temperature. I would need a negative feedback.

Any thoughts on how one would implement such a system?

@LSurf. Even though you mention E+ and OS in the heading of the question, it would not get emailed to E+ and OS subscribers unless you use the 'energyplus' and 'openstudio' tags. :)