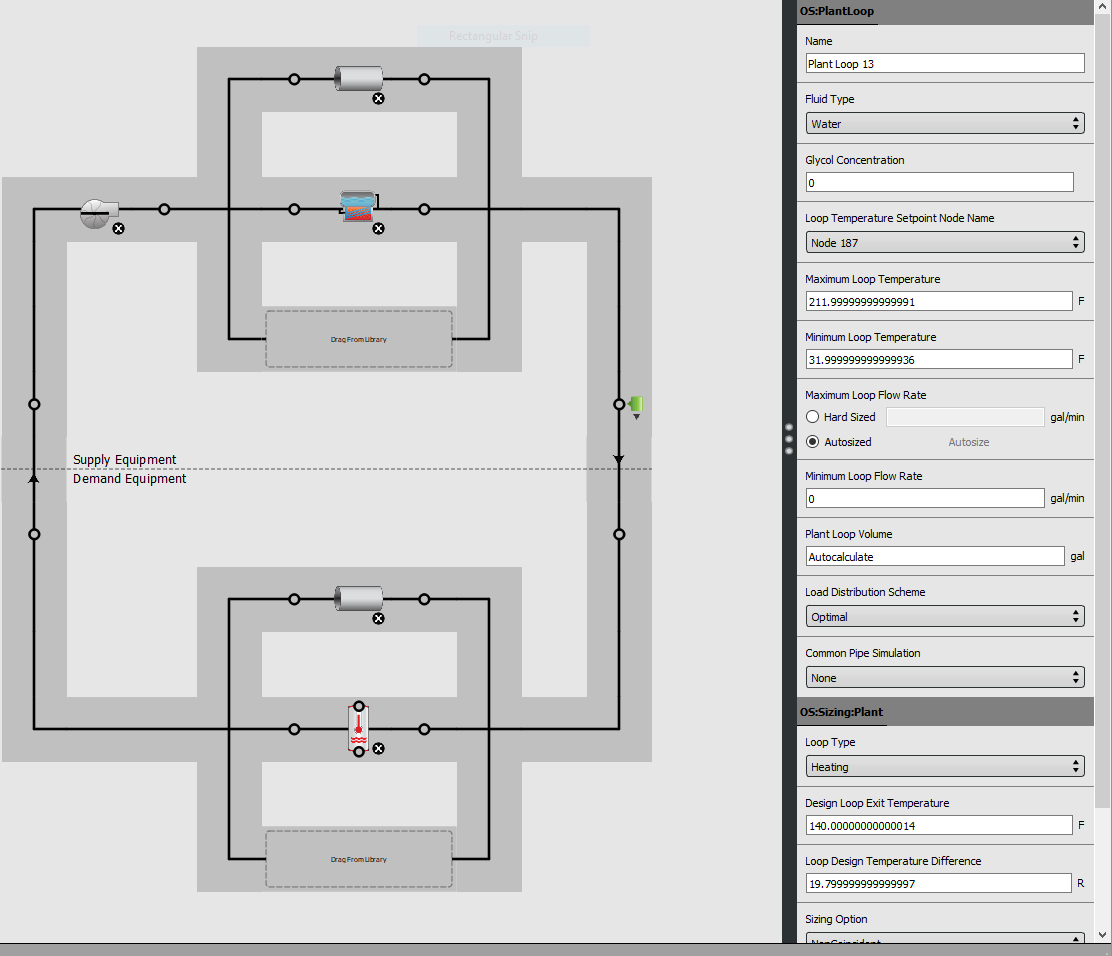

That Load Distribution Scheme input field ONLY applies when there are multiple pieces of supply equipment in the loop. For example, with two boilers setting this to "Optimal" will have one boiler operate at it's optimal PLR and the other boiler operate to meet the remaining load. If there's only one boiler, it has to meet all the load by itself, which is why you're seeing the same water heating energy usage results when changing it between "Optimal" and "SequentialLoad".

To model a two-stage boiler in OpenStudio, I would recommend adding two boilers to the supply side. Each boiler would represent a stage, so that you can define the appropriate parameters separately (capacity, efficiency, flow rate, min/max PLR, biquadratic performance curve coefficients, etc.). Now, to have the boilers operate independently (i.e. first-stage boiler runs by itself for low loads and second-stage boiler runs by itself for higher loads), you'll need to do some editing to the EnergyPlus IDF generated by OpenStudio. I say that because you will need to update things that are not exposed in OpenStudio:

- the PlantEquipmentOperationSchemes input structure that defines what kinds of load a plant loop tries to meet (heating loads, in this case) and min/max heating load ranges.

- Each min/max heating load range references a PlantEquipmentList object that defines what supply equipment will operate when the system sees a load value within that range.

So, using an example of staging 0 - 50kW and then 50-100kW, your updated PlantEquipmentOperationSchemes input structure will look like:

PlantEquipmentOperationSchemes,

HW Loop Operation, !- Name

PlantEquipmentOperation:HeatingLoad, ! Control Scheme 1 Object Type

Boiler Staging, !- Control Scheme 1 Name

AlwaysOn; !- Control Scheme 1 Schedule

PlantEquipmentOperation:HeatingLoad,

Boiler Staging, !- Name

0, !- Load Range 1 Lower Limit

50000, !- Load Range 1 Upper Limit

Boiler First Stage List, !- Load Range 1 Equipment List Name

50000, !- Load Range 2 Lower Limit

100000, !- Load Range 2 Upper Limit

Boiler Second Stage List; !- Load Range 2 Equipment List Name

PlantEquipmentList,

Boiler First Stage List, !- Name

Boiler:HotWater, !- Equipment 1 Object Type

Boiler Stage 1; !- Equipment 1 Object Name

PlantEquipmentList,

Boiler Second Stage List, !- Name

Boiler:HotWater, !- Equipment 1 Object Type

Boiler Stage 2; !- Equipment 1 Object Name

Boiler:HotWater,

Boiler Stage 1, !- Name

...

Boiler:HotWater,

Boiler Stage 2, !- Name

...

Actual names of the Boiler:HotWater objects will be what you defined in OpenStudio.