Why is the boilers.idf condensing boiler curve so linear?

TLDR: The sample EnergyPlus condensing boiler curve doesn't look like a typical condensing boiler curve. Is there something wrong with it?

Samples for boiler performance curves are available in boilers.idf.

The first curve is for a "Gas-fired condensing boiler...Use curve below for a condensing boiler having a nominal thermal efficiency of 0.89" and consists of:

Curve:Biquadratic,

CondensingBoilerEff, !- Name

1.124970374, !- Coefficient1 Constant

0.014963852, !- Coefficient2 x

-0.02599835, !- Coefficient3 x**2

0.0, !- Coefficient4 y

-1.40464E-6, !- Coefficient5 y**2

-0.00153624, !- Coefficient6 x*y

0.1, !- Minimum Value of x

1.0, !- Maximum Value of x

30.0, !- Minimum Value of y

85.0; !- Maximum Value of y

In order to interpret this I looked in the EnergyPlus Input/Output Reference, section Boiler:HotWater, subsection Field: Normalized Boiler Efficiency Curve Name which indicates:

For all curve types PLR is always the x independent variable. When using 2 independent variables, the boiler outlet water temperature (Toutlet) is always the y independent variable.

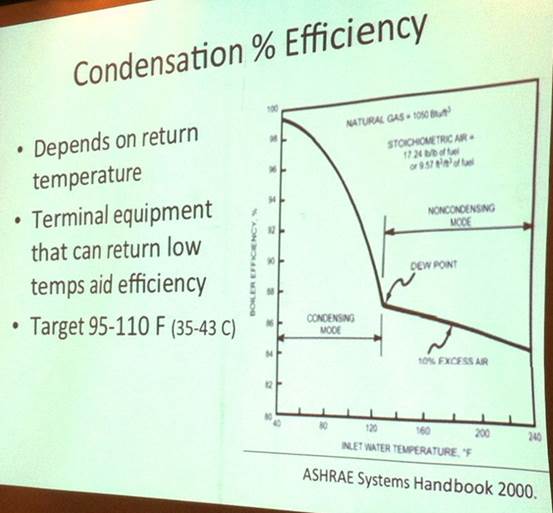

Based on that I plotted several curves, expecting to see a more-or-less typical curve for a condensing boiler which would have an inflection around ~120 F. Like this one:

(from http://www.greenbuildingadvisor.com/b... )

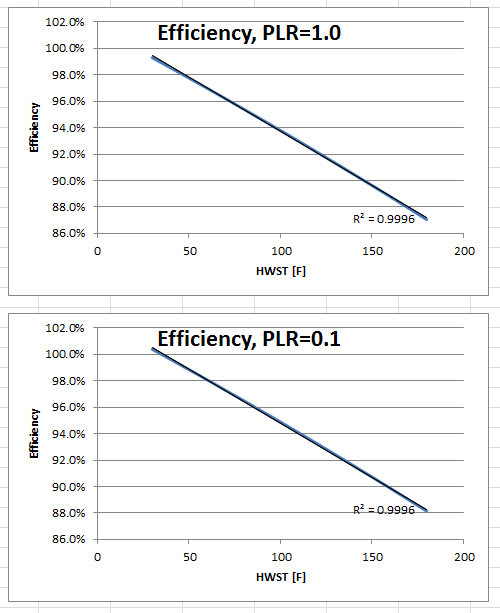

But instead it looks like this:

The trendlines are almost exactly linear. I don't think I've made an error plotting the curve, and you can see just from inspecting the coefficients that for a PLR held constant the supply temperature terms are quite small, especially the quadratic one.

Does this data really represent a condensing boiler?