ASHP tank not providing heat to storage plant loop

I have two IDFs which are substantially the same. They each have a primary HW loop, a PCM storage loop (two tanks in series) a secondary HW loop (baseboards and DHW). However one has a WaterHeater:HeatPump on the primary loop while the other has a Boiler:HotWater. The ASHP doesn't provide any heat to the PCM storage loop, while the gas boiler does. The PCM storage loop does provide heat to the secondary HW loop though since the tank temperature drops and the zones receive heat at the start of the run period (and I've checked the mass flow rate).

I have setpoint managers referencing set-points at the output node of each supply half-loop but it seems that one of the ones on the PCM loop is not working correctly when the ASHP is present. The ASHP gets up to temperature but doesn't provide any heat.

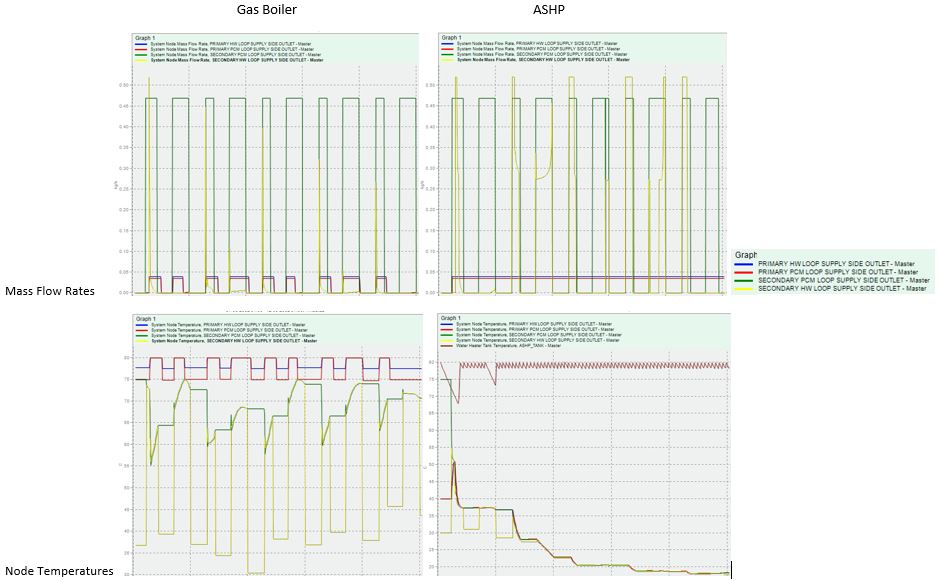

Here are a few charts which might help identify what's wrong.

As I read them, the ASHP tank temperature (the unlabelled line in the bottom right chart) is staying high but no heat is ever drawn from it, meaning that all the other nodes lose heat which is not replaced. I've checked and the mass flow rate from the ASHP WaterHeater:Mixed tank is zero at all times while the other tanks all provide flow when there is heat demand from the zones. Why would this be happening?