How can I model SetpointManager:Warmest, with a variable Maximum Setpoint Temperature?

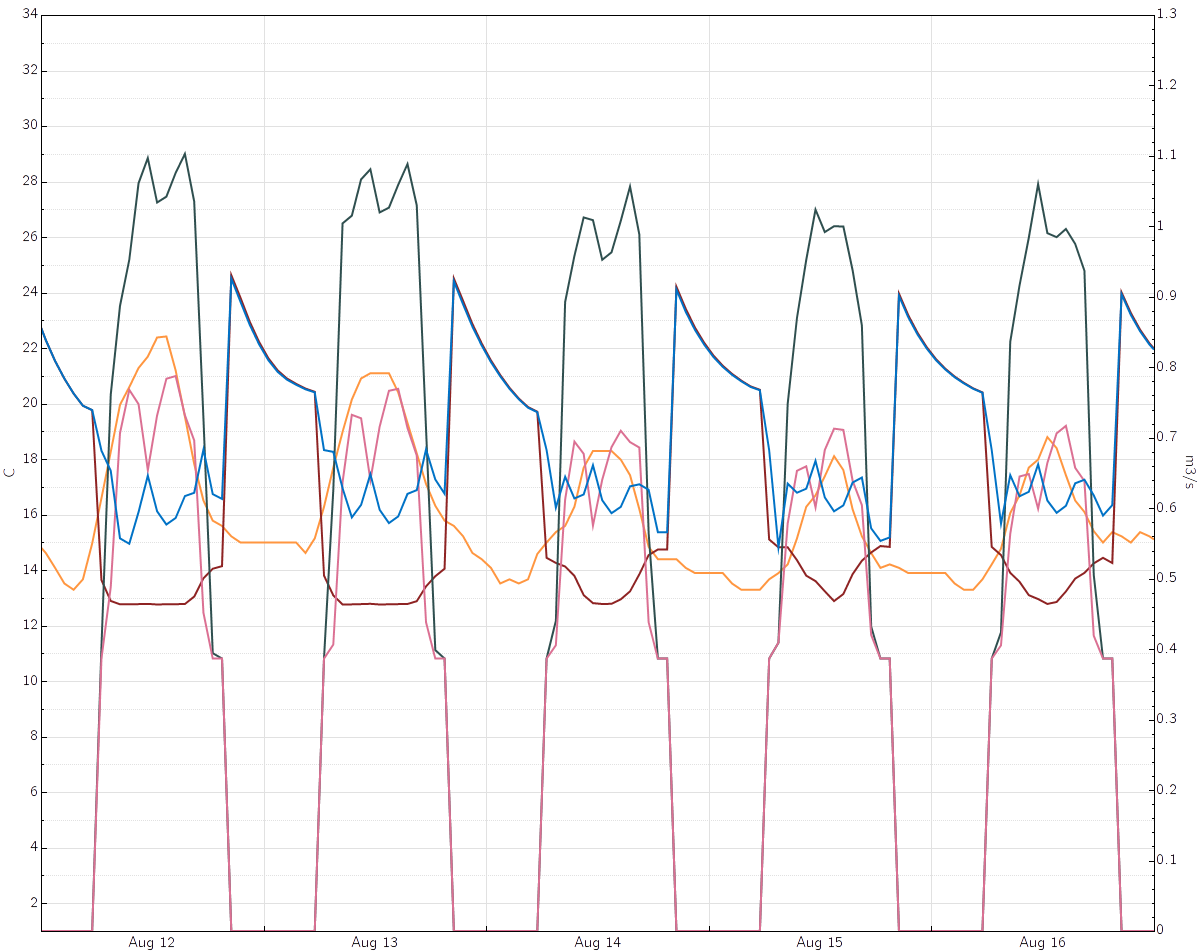

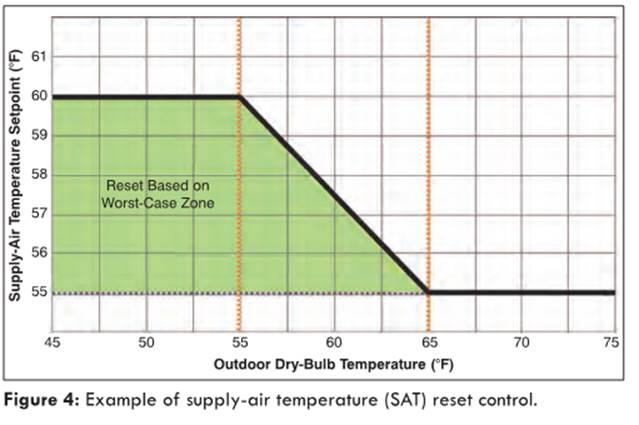

In Energy Plus, I would like to implement a load-based supply air temperature reset control for a multiple zone VAV system, where the maximum allowable reset supply air temperature varies with outside air temperature as shown in this figure:

The figure is from this ASHRAE journal article. And it is similar to the control sequence recommended in the Advanced Variable Air Volume System Design Guide (page 101).

The object SetpointManager:Warmest has a field for Maximum Setpoint Temperature that accepts a fixed value, not a schedule.

How can I implement this?

I noticed in the EMS Application Guide that there is an EMS actuator for System Node Setpoint with controlled component of Temperature Maximum Setpoint. Can I use this? Since the SetpointManager:Warmest seems to set both the supply air temperature setpoint at the node, as well as the supply air flow rate to each zone (as far as I could tell) I do not understand if this actuator could be used to effect the results of SetpointManager:Warmest and if so, what calling point to use it with.

If I have to use EMS to implement this control sequence, then: am I correct that I will need write an EMS program to set both the setpoint temperature at my fan outlet node to control the system supply air temperature, AND also set the flow rate for each and every zone served on the multiple zone system (based on the zone load and the system supply temp)?