How can we model ASHRAE 90.1-2004 Compliant Chilled/Condensing Water Loop Pumps?

Please scroll down to review the sections from ASHRAE 90.1-2004 Appendix G regarding modeling of chilled/condensing water loop pumps. Below are our 2 questions:

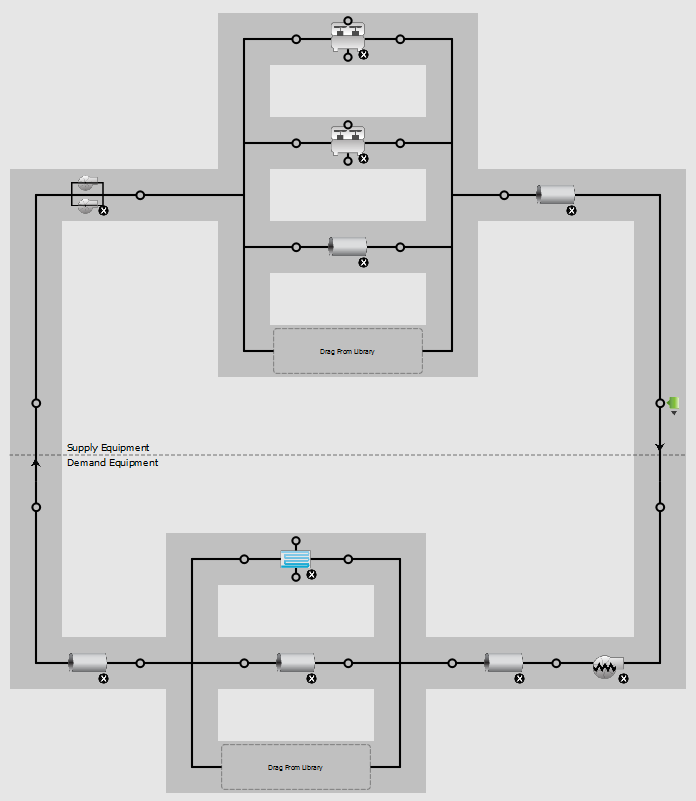

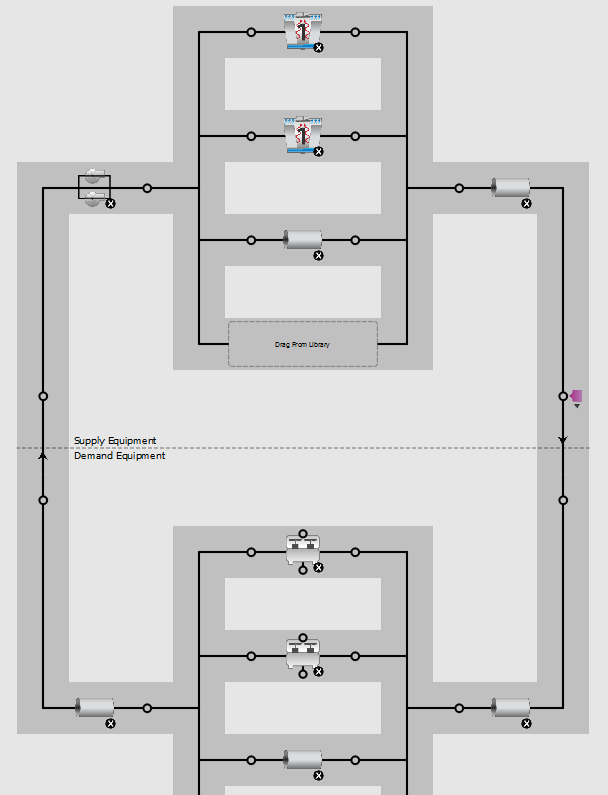

To model chilled/condensing water loop pumps in compliance with ASHRAE 90.1-2004, should we be modeling pump per chiller configuration both for the chilled water and condensing water loop? Or, should we use headered pumps (each with as many pumps as chillers) both for the chilled water and condensing water loop?

Appendix G says none of the chillers should exceed 800 tons in the baselines. In very large projects, we end up calculating more than 10 chillers per loop when we assume maximum of 800 tons each. Yet, EnergyPlus does not allow for more than 10 chillers per loop. What should we do in these cases? Should we divide the building into multiple chilled water loops so that each loop has a max of 10 x 800 tons = 8000 tons? Or, should we model the whole building with a single chilled water loop with 10 chillers even if we end up exceeding 800 tons in each chiller?

Relevant sections from ASHRAE 90.1-2004 Appendix G:

G3.1.3.7 Type and Number of Chillers (Systems 7 and 8)… The baseline building design’s chiller plant shall be modeled with chillers having the number and type as indicated in Table G3.1.3.7 as a function of building conditioned floor area. Building- Conditioned Floor Area Number and Type of Chiller(s)

- ≤120,000 ft2 1 screw chiller

- >120,000 ft2, <240,000 ft2 2 screw chillers sized equally

- ≥240,000 ft2 2 centrifugal chillers minimum with chillers added so that no chiller is larger than 800 tons, all sized equally

G3.1.3.10 Chilled Water Pumps (Systems 7 and 8). The baseline building design pump power shall be 22 W/gpm. Chilled water systems serving 120,000 ft2 or more shall be modeled as primary/secondary systems with variable-speed drives on the secondary pumping loop. Chilled water pumps in systems serving less than 120,000ft2 shall be modeled as a primary/secondary systems with secondary pump riding the pump curve.

G3.1.3.11 Heat Rejection (Systems 7 and 8)…. The baseline building design condenser water pump power shall be 19 W/gpm. Each chiller shall be modeled with separate condenser water and chilled water pumps interlocked to operate with the associated chiller.