Many unmet cooling hours with radiant floor with DOAS possibly due to condensation shutoff

I'm using OpenStudio Version 2.1.

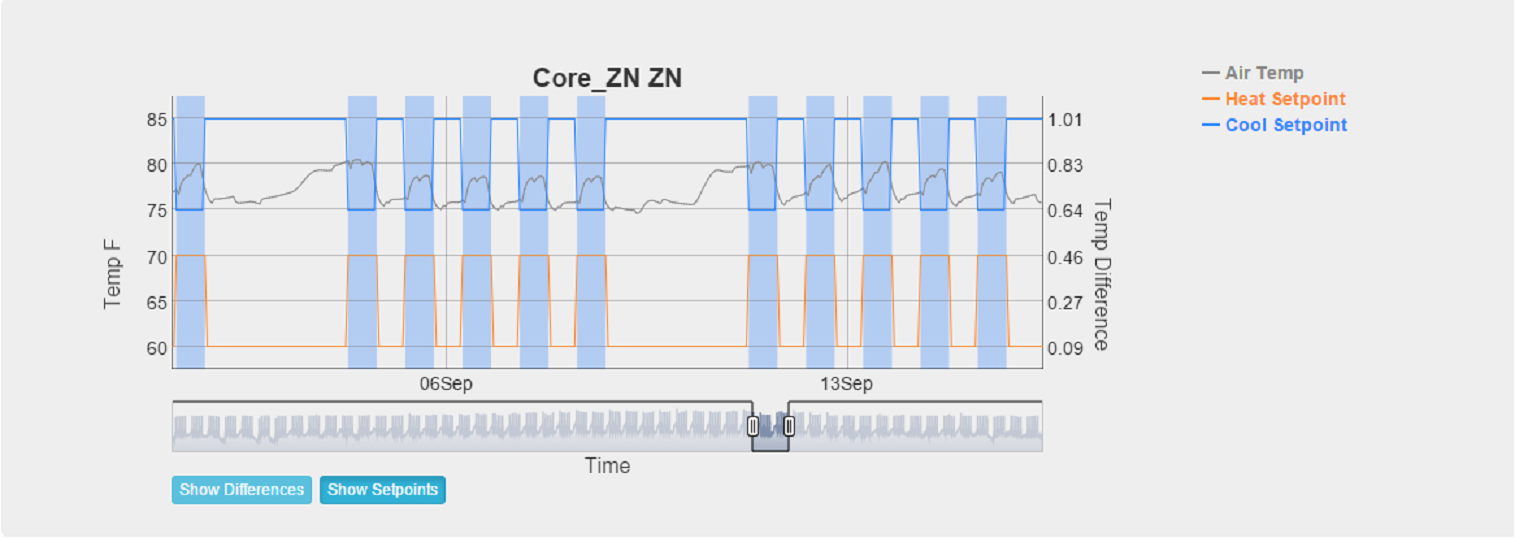

I applied the 'AEDG Office HVAC Radiant with DOAS' measure to a small office building and ran the model. The model came back with over 2,000 unmet cooling hours. See below for an image of the Unmet Hours Troubleshoot for one of the zones:

I then noticed that I am receiving the following an error such as the one below for each thermal zone:

*** * Warning * ZoneHVAC:LowTemperatureRadiant:VariableFlow [ZONE HVAC LOW TEMPERATURE RADIANT VARIABLE FLOW 3] condensation shut-off occurrence continues. *** * ~~~ * This error occurred 3260 total times; *** * ~~~ * during Warmup 0 times; *** * ~~~ * during Sizing 0 times. *** * ~~~ * Max=24.454547 C Min=19.09359 C

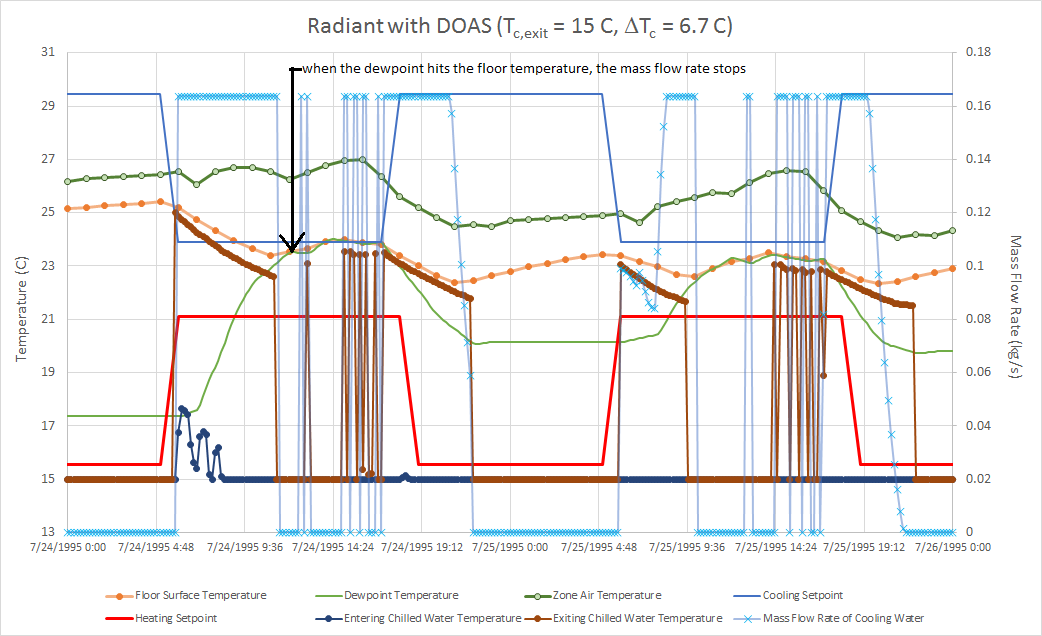

Reading the input/output reference seems to indicate that the system is turning off because the panel was cool enough to cause the water in the air to hit it's dew point, causing condensation. This makes sense to me since I know that is a design consideration for radiant systems. Is this correct?

The design temperature for the cooling loop is 59 F with an 8 degree Delta T. I've tried changing this around a bit (with the associated radiant cooling temperature schedule), but have had little luck on getting rid of the unmet cooling hours due to the same error (assumption). Anyone have any advice on getting rid of the condensation? It's also totally possible (probable?) that I could be missing something else that is causing the unmet cooling hours.

Edit:

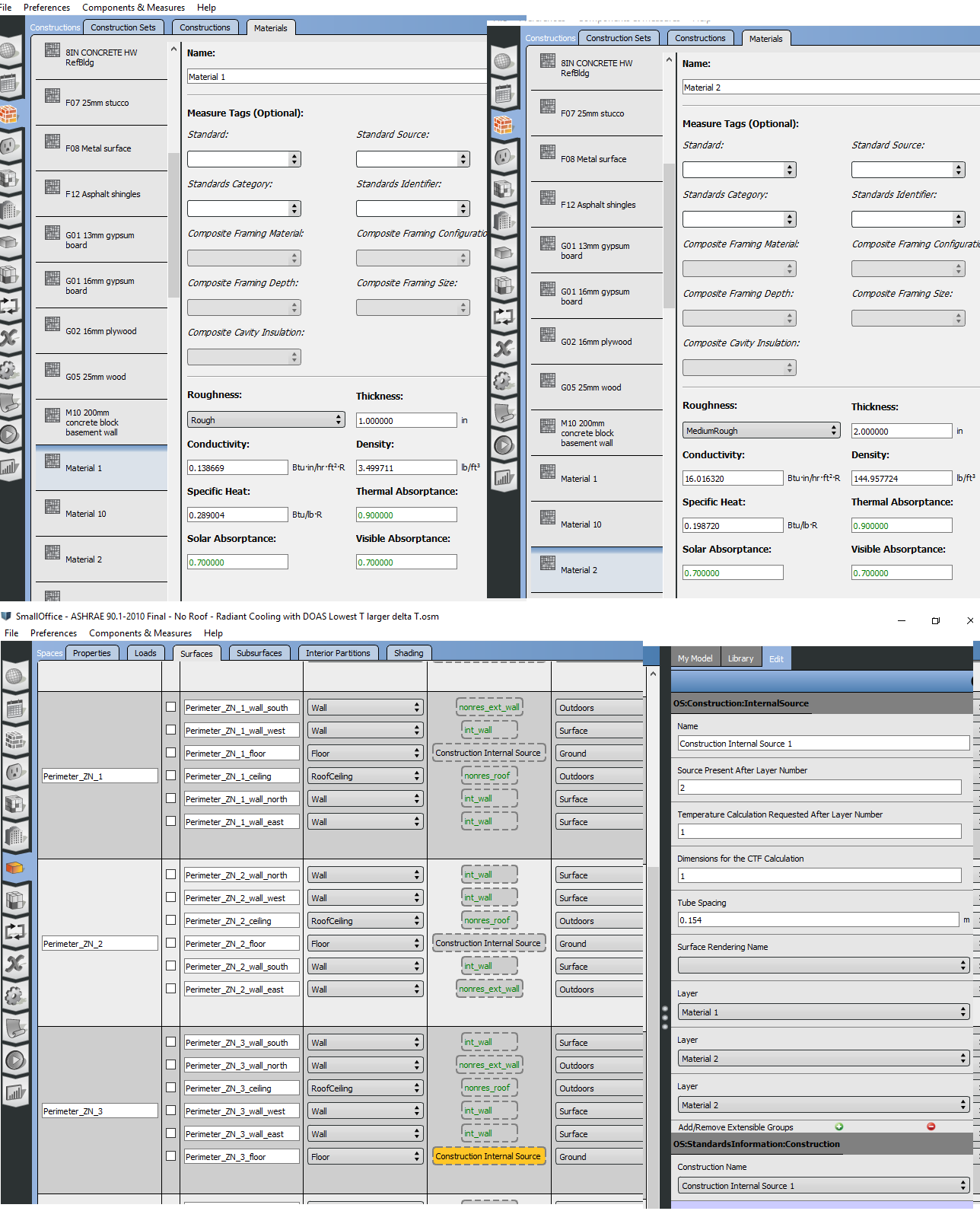

I looked into the issues that @rsunnam suggested. I checked the constructions and the internal construction source and it appears to have no issues. The material layers 2 and 3 indicate that it is 2 inches of concrete followed by the radiant tubes and then 2 more inches of concrete, which appears to be satisfactory according to this post. See image below for screenshots of the internal construction:

After checking that, I decided to graph the model that I initially posted about in order to prove that the pump was shutting off when the dew point temperature hit the floor temperature. This model had 1940 unmet cooling hours. See diagram below for a typical week:

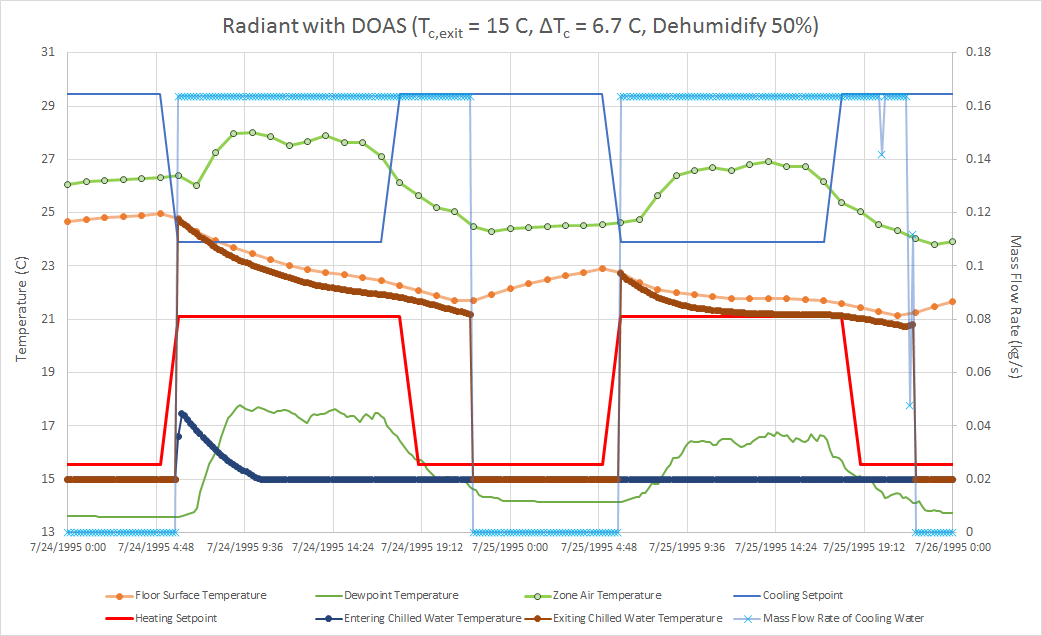

Seeing that the pump was turning off due to the dew point temperature, I put in dehumidifier and set a humidistat to turn on when there is a relative humidity of more than 50%. This worked to eliminate the condensation shut off, but actually increased the unmet cooling hours to 2200! See diagram below for a typical week:

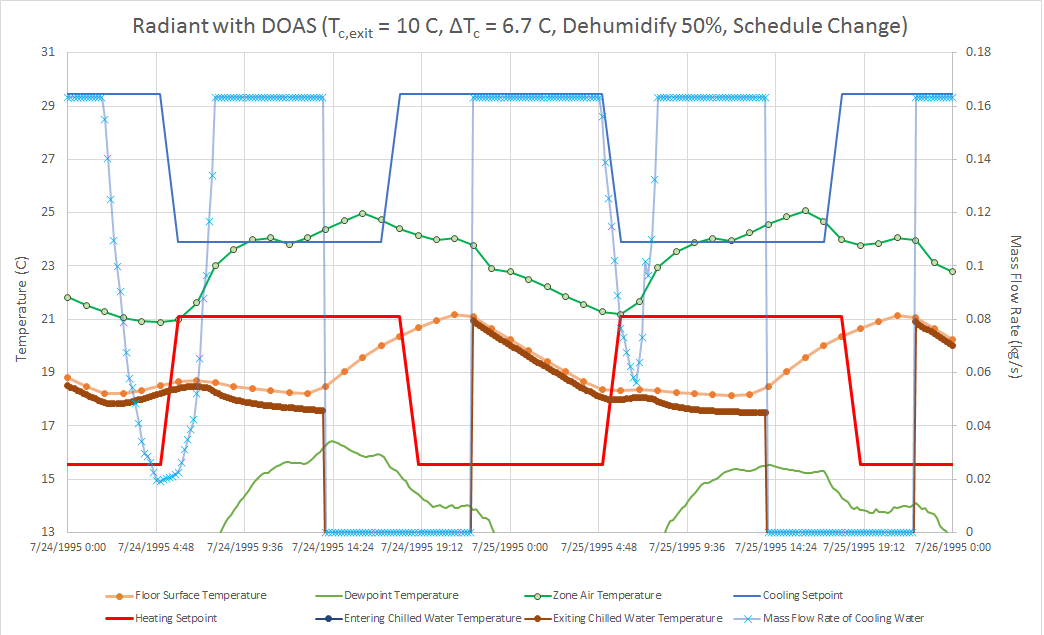

I then decided to change the cold water temperature schedule to activate earlier in the night and lowered the exit water temperature to 10 degrees C. This significantly lowered the unmet cooling hours to 900, but I'm still having issues getting it under my target number of 300. See diagram below for a typical week:

I'm still unsure if i have an error in my model causing these issues or if the location I have chosen (Houston) just can't ...

Hi @Jonathan K For these kinds of systems, I usually verify the flow through the LowTemp Radiant components to confirm their operation. If there is flow through them, I check the internal source constructions. Having the source layer at the correct location is critical to ensure that the zones are conditioned without a timelag. Also I check the internal loads and radiant cooling schedules to ensure that they start around the same time. For your model, did you verify that these components have zero flowrate due to condensation shutoff?

Thank you @rsunnam. I checked many of your suggestions and updated above.

Trying to do radiant cooling in Houston is a questionable design decision in my opinion.You're going to be fighting with the environment quite a bit due to how humid the climate is there. The dehumidification energy required to prevent it from raining (panels) or forming a lake (in-floor) just isn't worth it.

Hi @Jonathan K I cant speak to the design decisions about having radiant cooling panels in Houston. Wrt the model, I suggest that you take a look at this post. The next thing I would check is the capacity and the dT of inlet &outlet water temperatures and design capacity. Just as Annie mentions in her response in the post, we usually consider the design capacity of panels at 10K temp diff between the room air temp and panel surface temp. We manually calculate all the water flow rates based on these for E+.