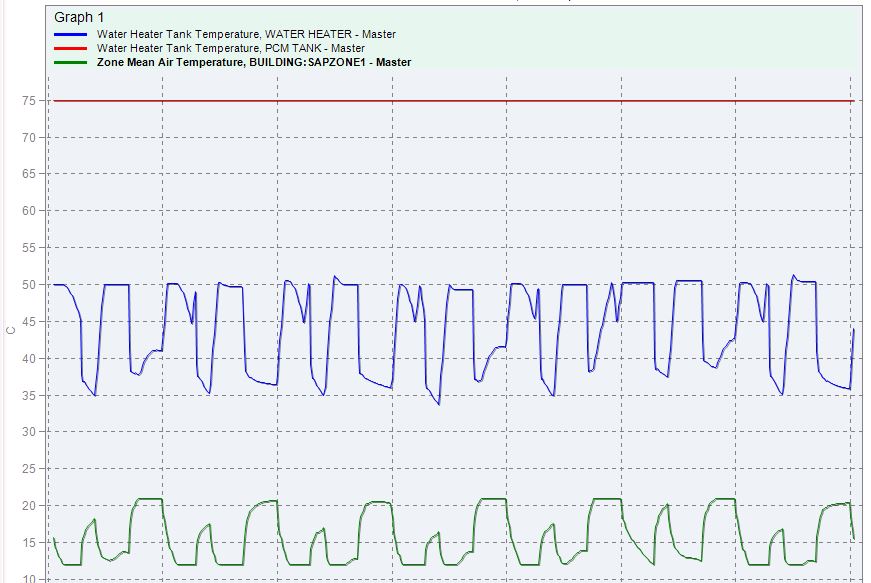

Why don't my parallel water heaters both supply heat?

I have two WaterHeater:Mixed objects in parallel, one with a setpoint of 50 C (Water Heater) and one with a setpoint of 80 C 75 C (PCM tank). This is the order they are listed in the EquipmentList so the one with a lower setpoint is drawn on first.

The question is why is the second tank not drawn from when the first tank can't meet the load?

Edited to add section of IDF

PlantLoop,

Secondary HW Loop, ! - Name of loop

Water, ! - Fluid type

, ! - User-defined fluid type

Secondary HW Loop Operation, ! - Plant equipment operation scheme

Secondary HW Loop Supply Side Outlet, ! - Loop temperature setpoint node

80.00, ! - Maximum loop temperature (C)

0.00, ! - Minimum loop temperature (C)

autosize, ! - Maximum loop flow rate (m3/s)

0.000000, ! - Minimum loop flow rate (m3/s)

autocalculate, ! - Volume of the plant loop (m3)

Secondary HW Loop Supply Side Inlet, ! - Plant side inlet node

Secondary HW Loop Supply Side Outlet, ! - Plant side outlet node

Secondary HW Loop Supply Side Branches, ! - Plant side branch list name

Secondary HW Loop Supply Side Connectors, ! - Plant side connector list name

Secondary HW Loop Demand Side Inlet, ! - Demand side inlet node

Secondary HW Loop Demand Side Outlet, ! - Demand side outlet node

Secondary HW Loop Demand Side Branches, ! - Demand side branch list name

Secondary HW Loop Demand Side Connectors, ! - Demand side connector list name

Uniform, ! - Load distribution scheme

Secondary HW Loop AvailabilityManager List, ! - Availability manager list name

SingleSetpoint, ! - Plant loop demand calculation scheme

None, ! - Common pipe simulation

None; ! - Pressure simulation type

PlantEquipmentOperationSchemes,

Secondary HW Loop Operation, ! - Name of plant/condenser equipment operation scheme

PlantEquipmentOperation:HeatingLoad, ! - Control scheme object type 1

Secondary HW Loop Scheme 1, ! - Name of control scheme 1

On; ! - Control scheme schedule 1

PlantEquipmentOperation:HeatingLoad,

Secondary HW Loop Scheme 1, ! - Name of control scheme

0.00, ! - Range lower limit 1

1000000000000000.00, ! - Range upper limit 1

Secondary HW Loop Scheme 1 Range 1 Equipment List; ! - Range equipment list name 1

PlantEquipmentList,

Secondary HW Loop Scheme 1 Range 1 Equipment List, ! - Range equipment list name 0

WaterHeater:Mixed, ! - Equipment 1 object type

Water Heater, ! - Equipment 1 name

WaterHeater:Mixed, ! - Equipment 1 object type

PCM Tank; ! - Equipment 1 name

I don't see any obvious reasons right off the bat and I haven't tried this before. Any chance you could share the idf, or the relevant sections for those parallel branches? Are you seeing any flow through the 80°C branch?

Apparently we can't upload IDFs here. The relevant section is in this pastebin.

And no, no flow at all through the 80°C branch.