Openstudio/energyplus precision cooling

Hi,

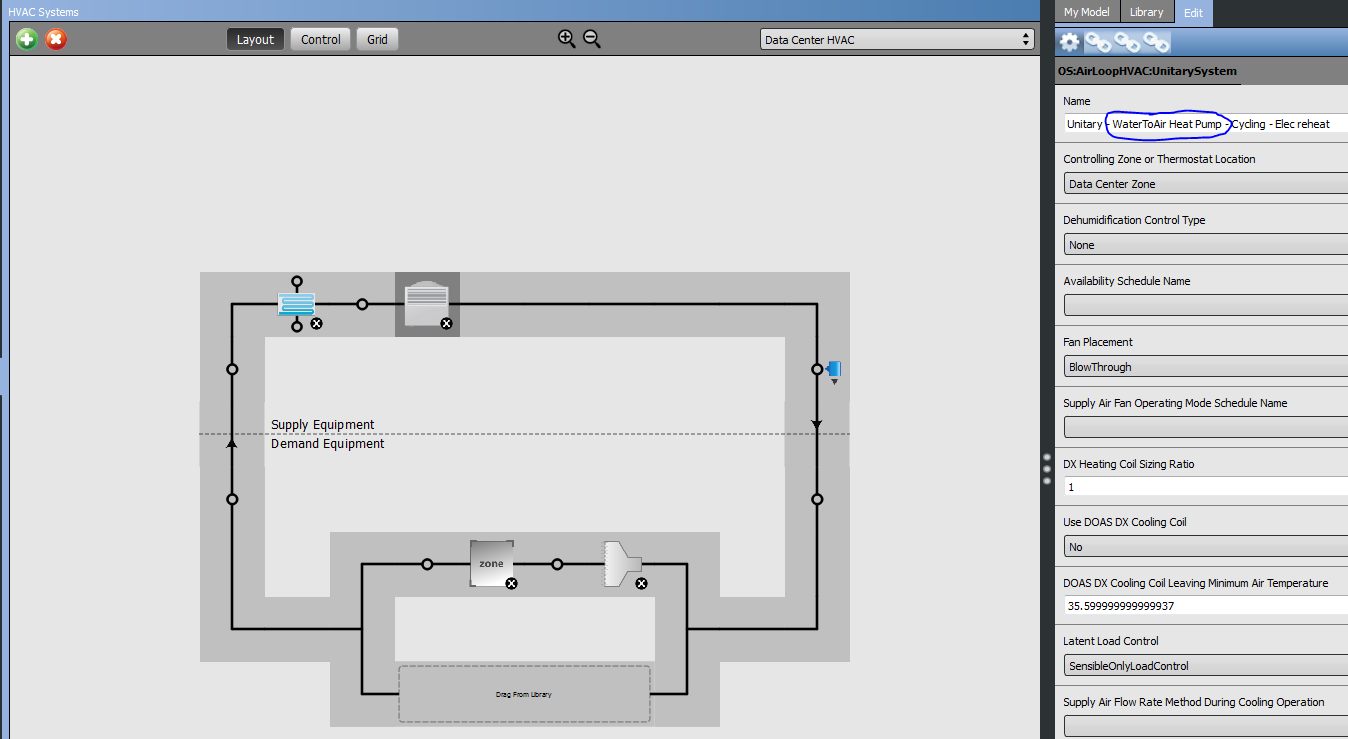

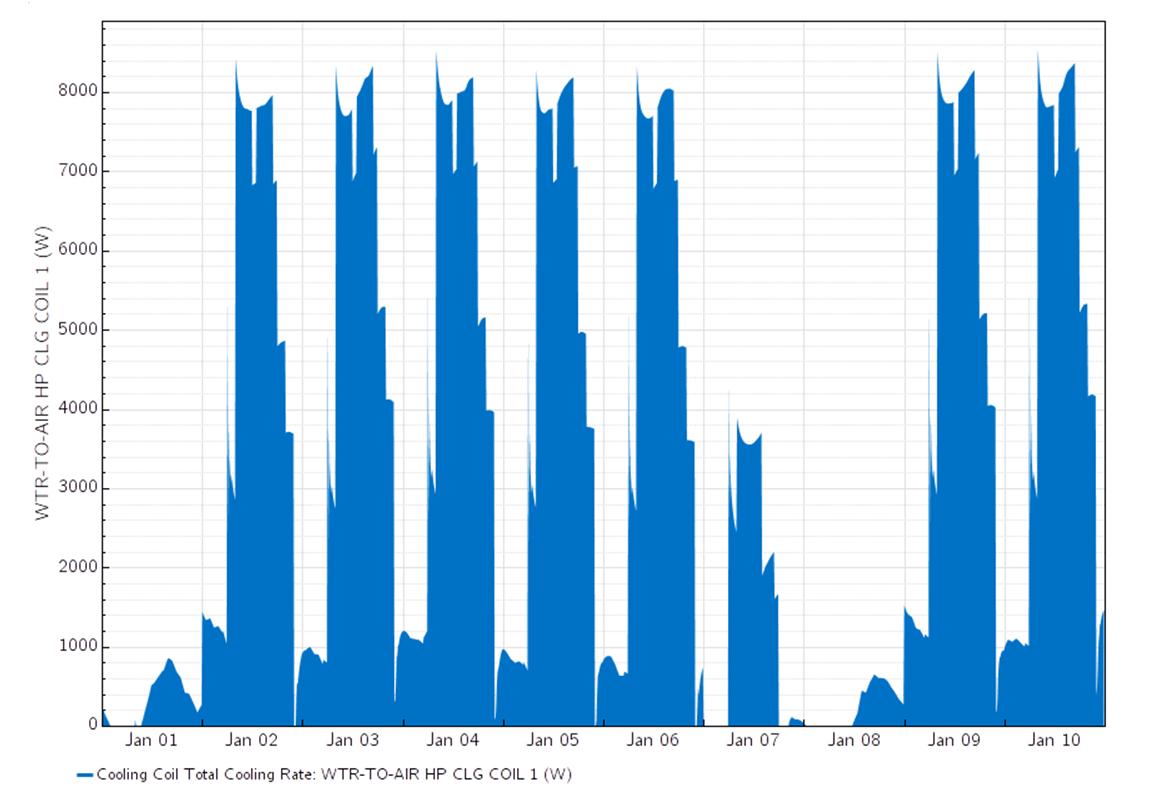

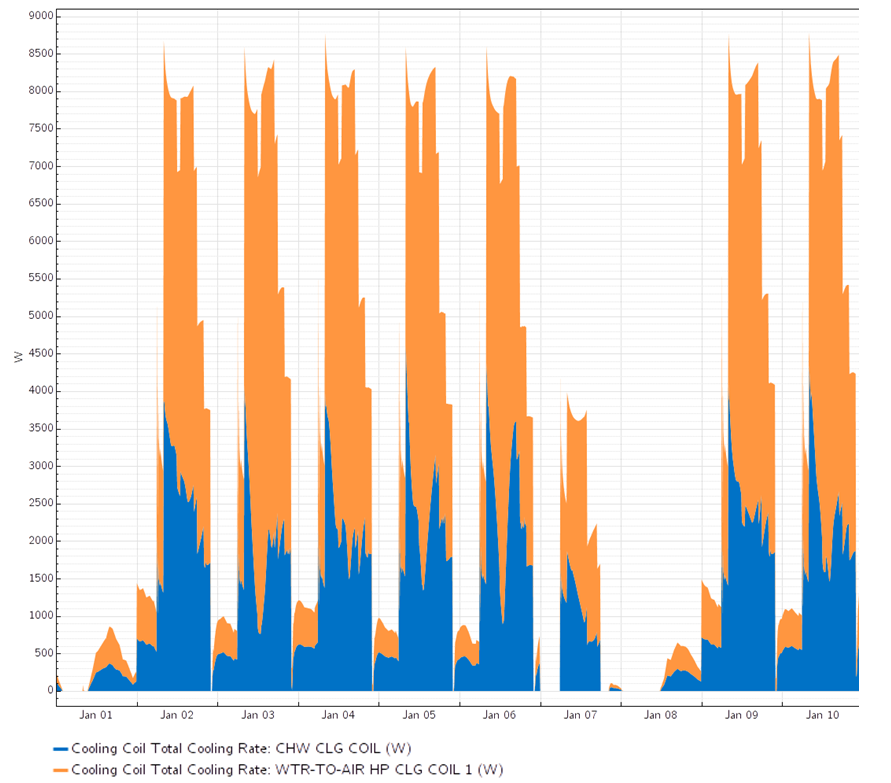

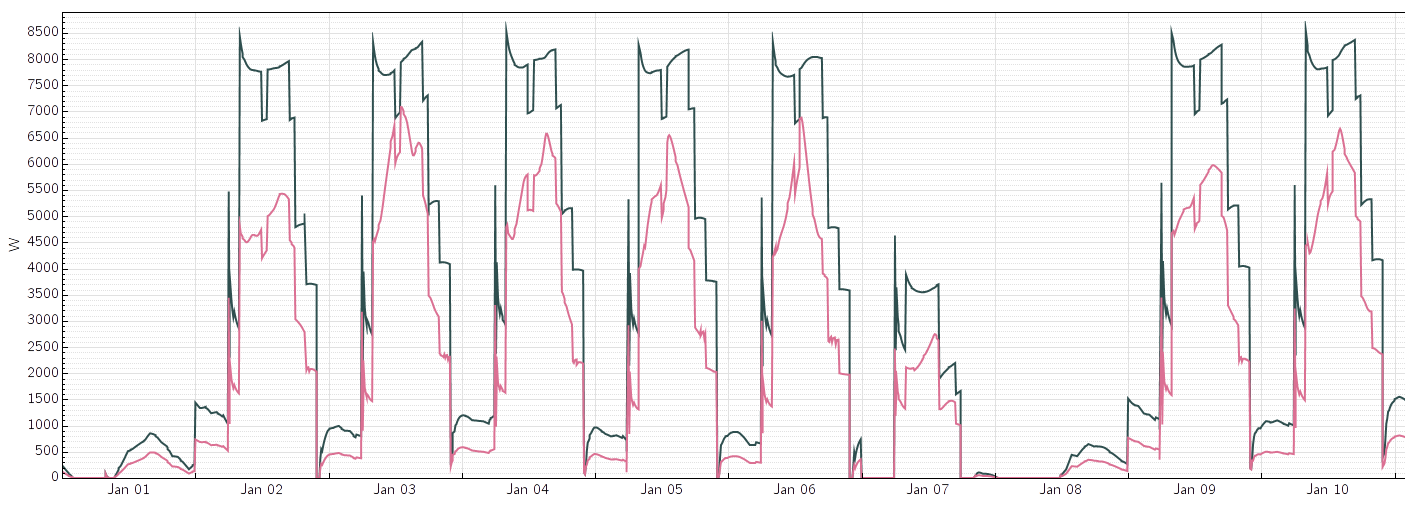

I´m trying to simulate a one thermal zone datacenter with a precision cooling air conditioning system, formed by a water condenser dx coil (water to air heat pump zone equipment) and a water coil, located in Bogota Colombia. Some hours at the day, its very common to use dry coolers fore full dx operation, several hours at the day we can use the dry cooler with water-cooled dx system and water coil at the same time (partial indirect free cooling), ant other hours total indirect freecooling to cool the datacenter.

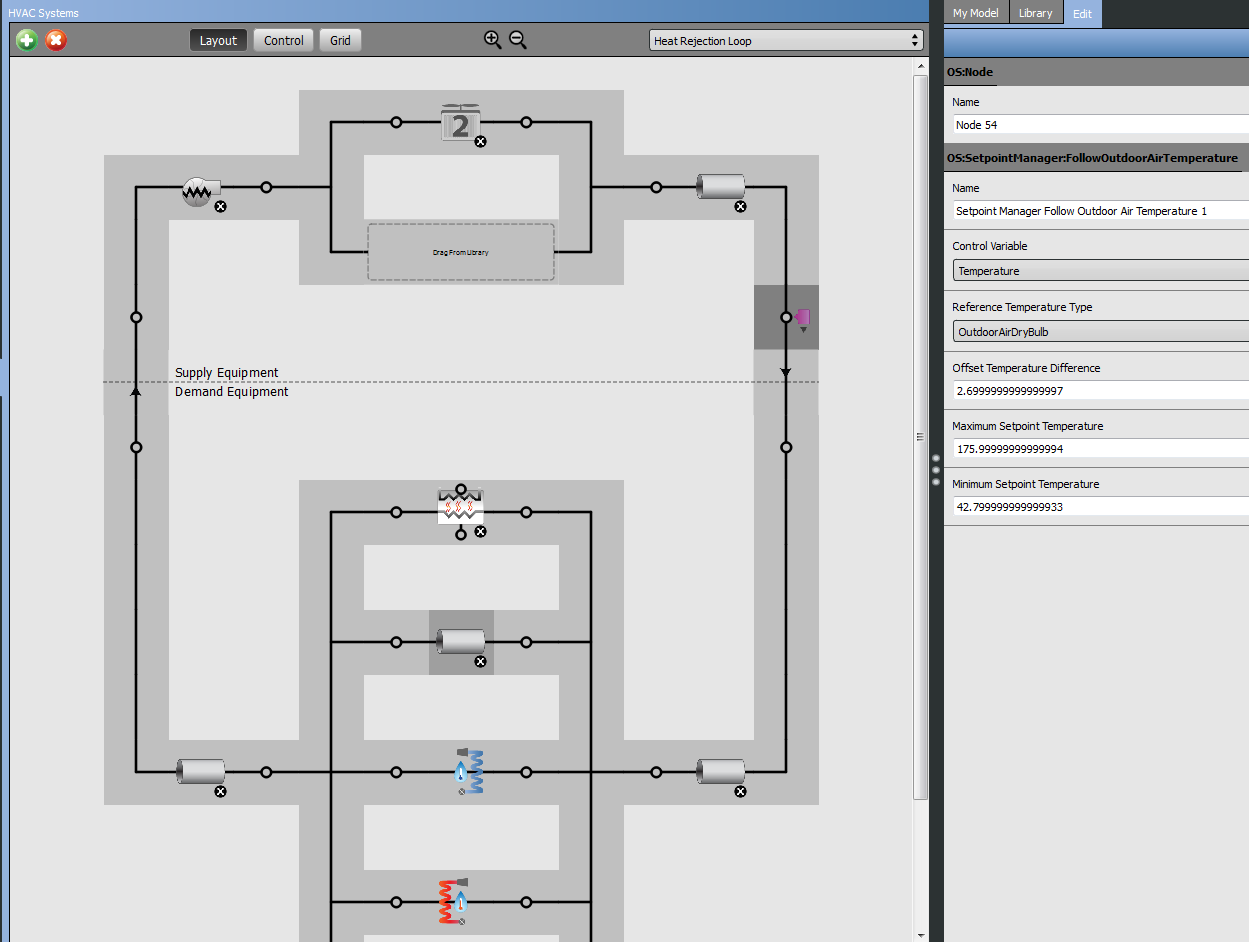

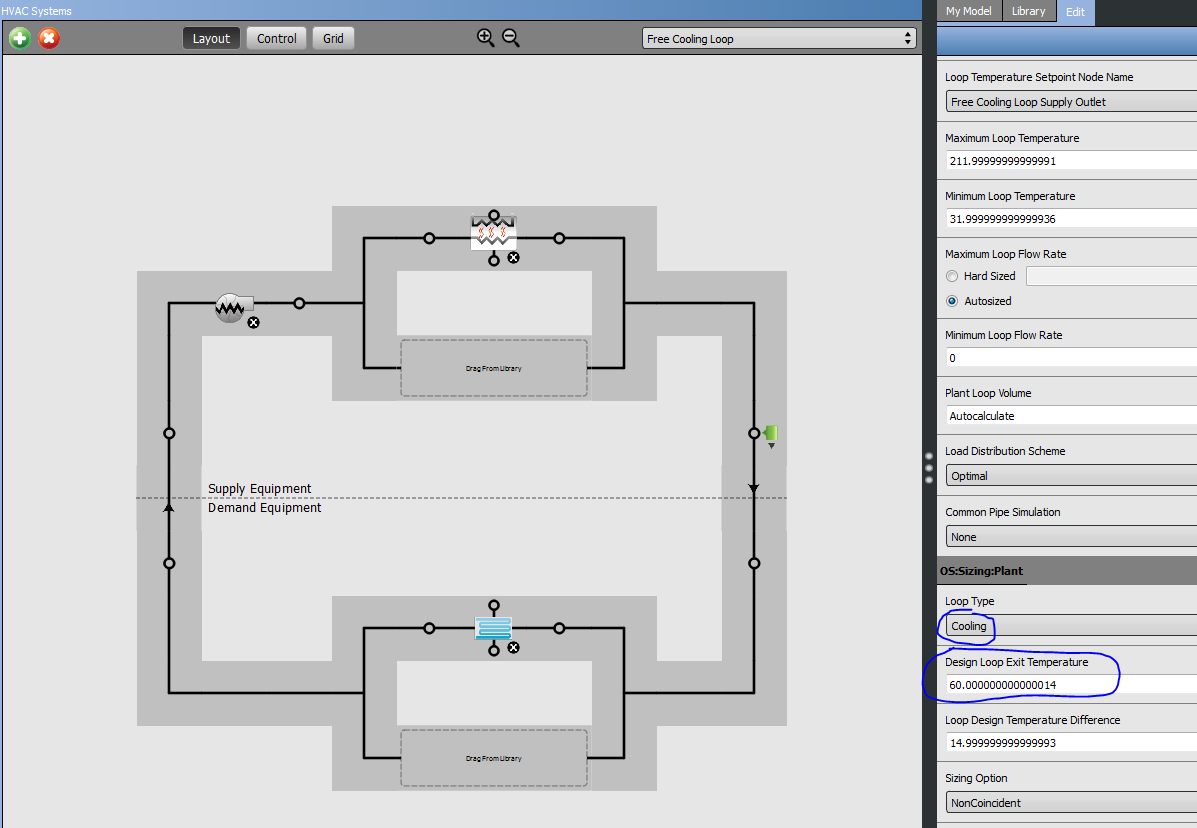

The thing is the coil an the zone equipment are in the same water loop, the question is. How can i set the coil operation to be available only when the water loop temperature leaving the dry cooler is below the air supply temperature, and turn off the dx coil when the water loop leaving the dry cooler is below 60°F.

In the water loop, which set point manager is better for dry coolers? If there are two different system in the water loop (cooling water coil and water to air heat pump) which loop type do i need to set? cooling, condenser ? C:\fakepath\DATACENTER.jpg