Sizing Fluid to Fluid Heat Exchanger. Energyplus results interpretation.

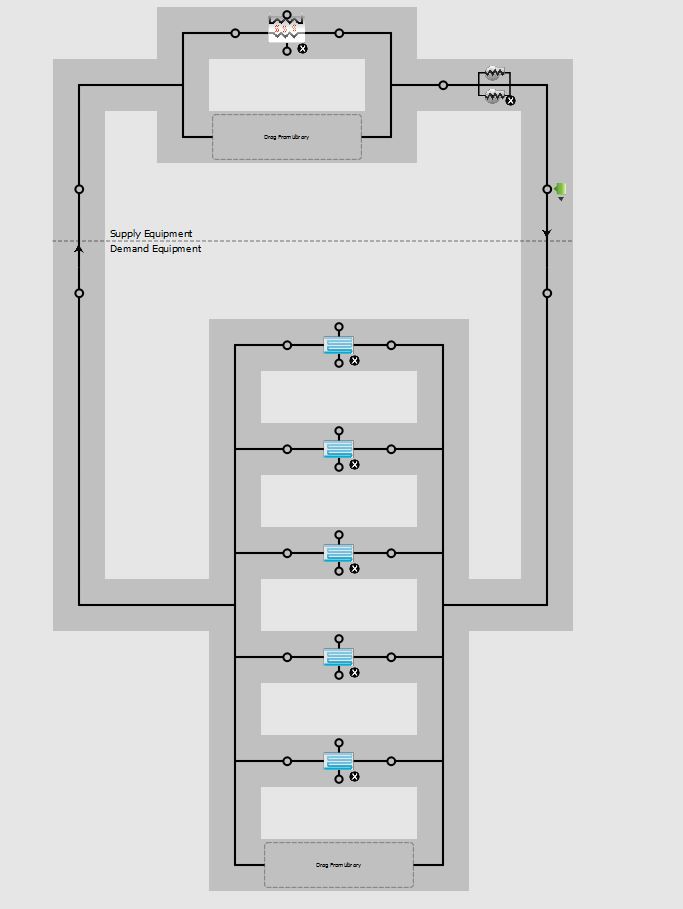

Hi! I need help to interpret the results that I am getting of a model I´m doing in openstudio. This is a chilled water secondary plant loop diagram. The supply side is a fluid to fluid heat exchanger and the demand side are the different cooling coils located in a multi-story office building. The primary loop is a typical chilled water primary loop with chillers and pumps (not shown in diagram). The plant sizing result for the primary chiller water loop is 1,366 tons, which is an expected result for me. The plant sizing for the secondary chilled water loop coincides with the primary in terms of design water flows for both supply and demand side (both have the same design temperature difference). But, for the heat exchanger, the sizing results are different: 1,590 tons if I choose an ideal heat exchanger type (16.3% over the primary plant size); and 735 tons if I choose a counterflow heat exchanger type (53.8% of the primary plant size). I have been reading energyplus engineering reference and Input/Ouput manuals to see if I find an explanation about why I am getting these results but so far I have not. Any help will be appreciated. Thank you!