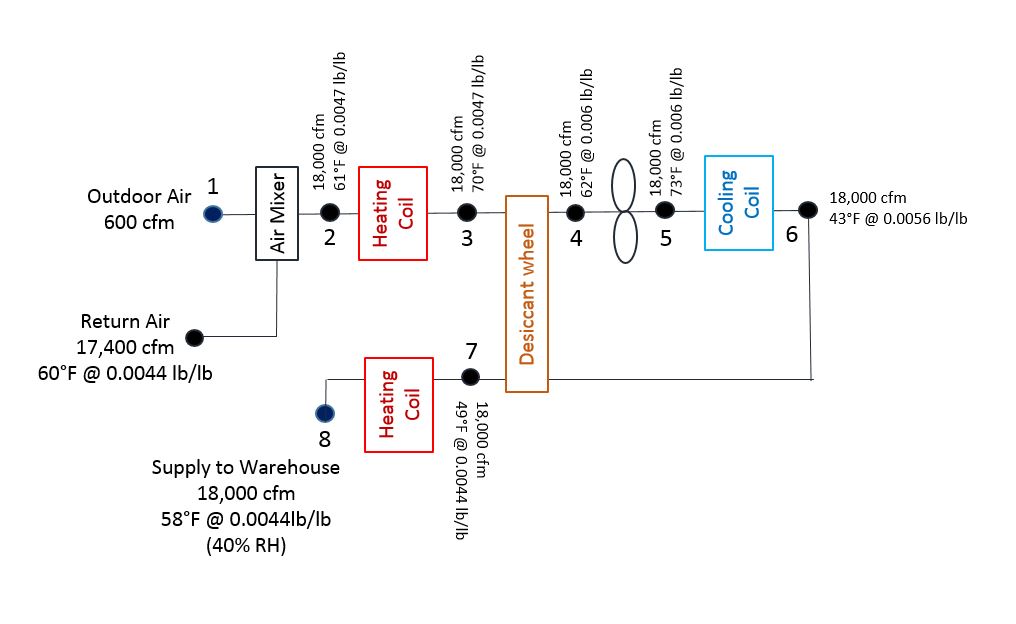

Desiccant Wheel with both sides in the Supply Flow

I have a system I have not modelled before and thought that the clever unmethours people might be able to help, or at least point me to some papers / forum answers that have dealt with this topic before. I have a system which has a desiccant wheel in the middle of a unit and only within the supply air flow, moisture essentially moves from one side to the other on a continuous basis. I start with my outdoor air mixing with the return air, this then passes over a heating coil, which feds the top of the desiccant wheel (the regeneration air stream), the air is then passed over a fan, to a cooling coil and then back over the bottom of the desiccant wheel (process air stream) before being reheated. See image below:

I have all my coils and fans in place but not quite sure how to model this desiccant wheel. I see there is the Dehumidifier:Desiccant:NoFans object, which looks like it might let me be able to do this. I will be feel like it won't be able to have the regeneration nodes and the process nodes in the same air stream. Also it says that the minimum regeneration temperature is 40C whereas my heating coil only goes to 21.1C. So whilst i am playing with this i thought i could ask on here as well. Here are my main questions

- For the Dehumidifier:Desiccant:NoFans object, can this wheel reject heat and humidity into the same air stream that is the process air stream, or will it always try to reject to the outside environment?

- If it can reject to the same air stream where does this object sit in the branch list?

- if it can't does anyone have work around suggestions. I can keep the desiccant wheel in place for the process air stream and remove the energy used by the coil and fan in the regeneration air stream, but how can I account for the additional humidity and reduction in temperature between the heating coil and fan in the actual unit?

Thank you all in advance!