three-way valve or bypass valve in chilled water loop

In assembling a fairly detailed OpenStudio/EnergyPlus model of a building, I realized I may need to more accurately model the chilled water loop. At present, my loop only has a chiller, a variable speed pump and two air handlers (in parallel), whereby it appears as though the inlet nodes to the air handlers act as "two-way" valves (?).

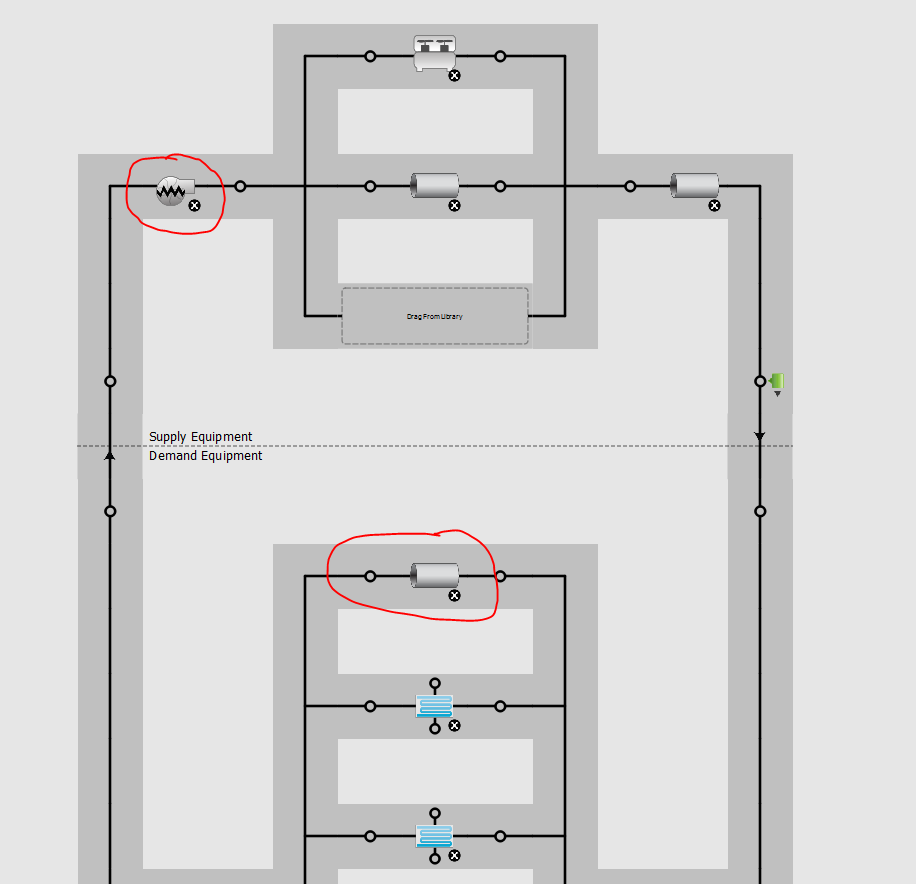

In actuality, one of the air handlers has a three-way valve with a bypass straight from the chilled water supply to the return line, i.e. when this air handler does not need all the cooling it can get, it simply bypasses the chilled water and contributes to a "low delta T" condition. Even if this three-way valve was not there, there would still have to be a bypass valve in this variable primary loop so as to ensure the chiller always sees its minimum flow requirement met (of course, this also contributes to a "low delta T" condition - necessarily so).

So, my question is, can these types of valves (and associated pipe runs) be accommodated by OpenStudio/EnergyPlus in order to more realistically represent the chilled water loop? I would imagine this configuration would make the pump work harder and/or make the chiller operate less efficiently and therefore would have a non-negligible impact on energy consumption?

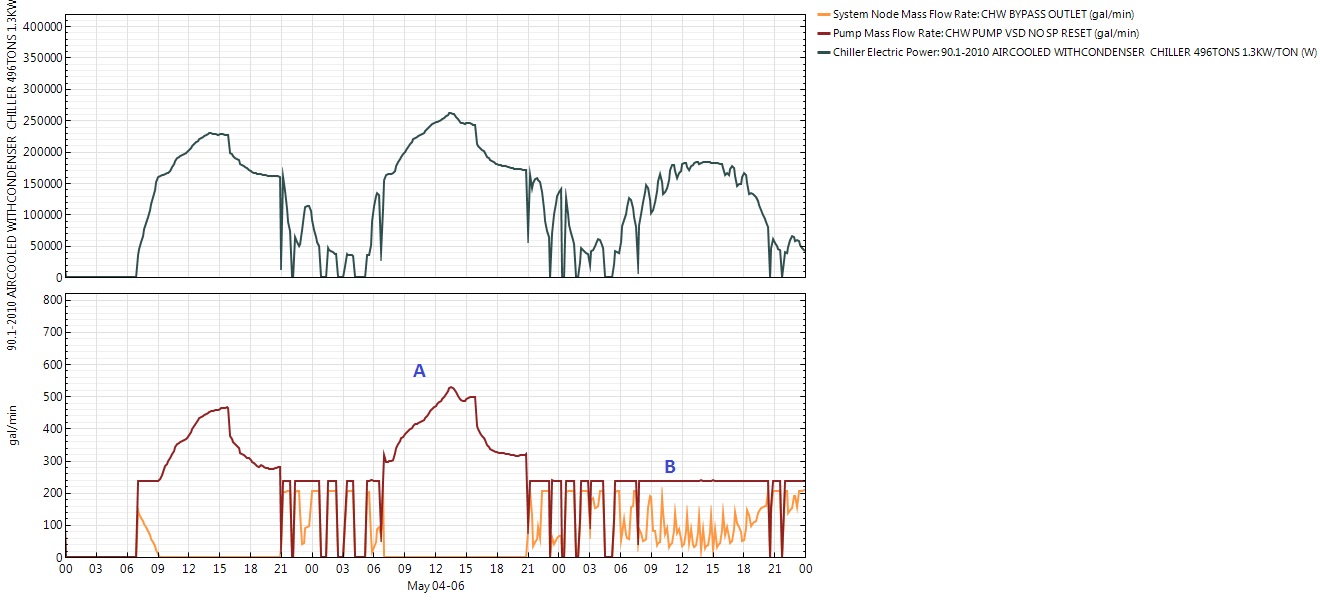

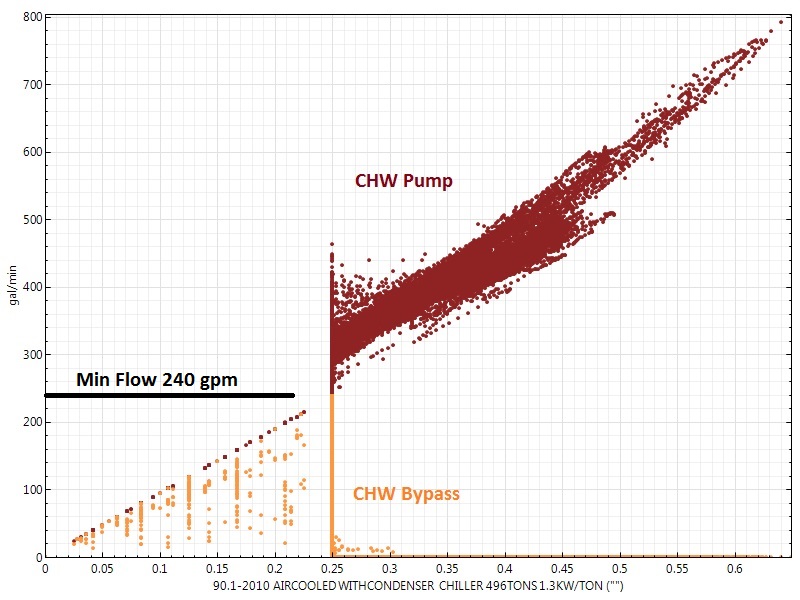

,

,  .

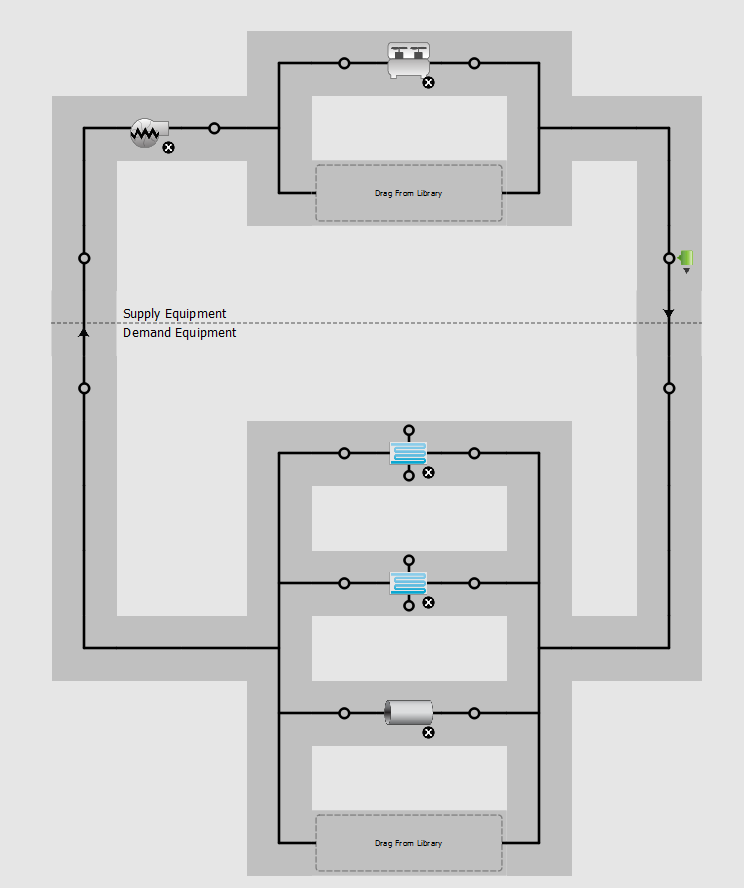

.