Heating demand not passed from DHW loop to Boiler loop

I've been struggling trying to model an indirect water heater, where a Boiler:HotWater operates in constant flow, variable temperature, trying to meet a setpoint in a water tank, that in turns serves WaterUse:Connections.

Short story

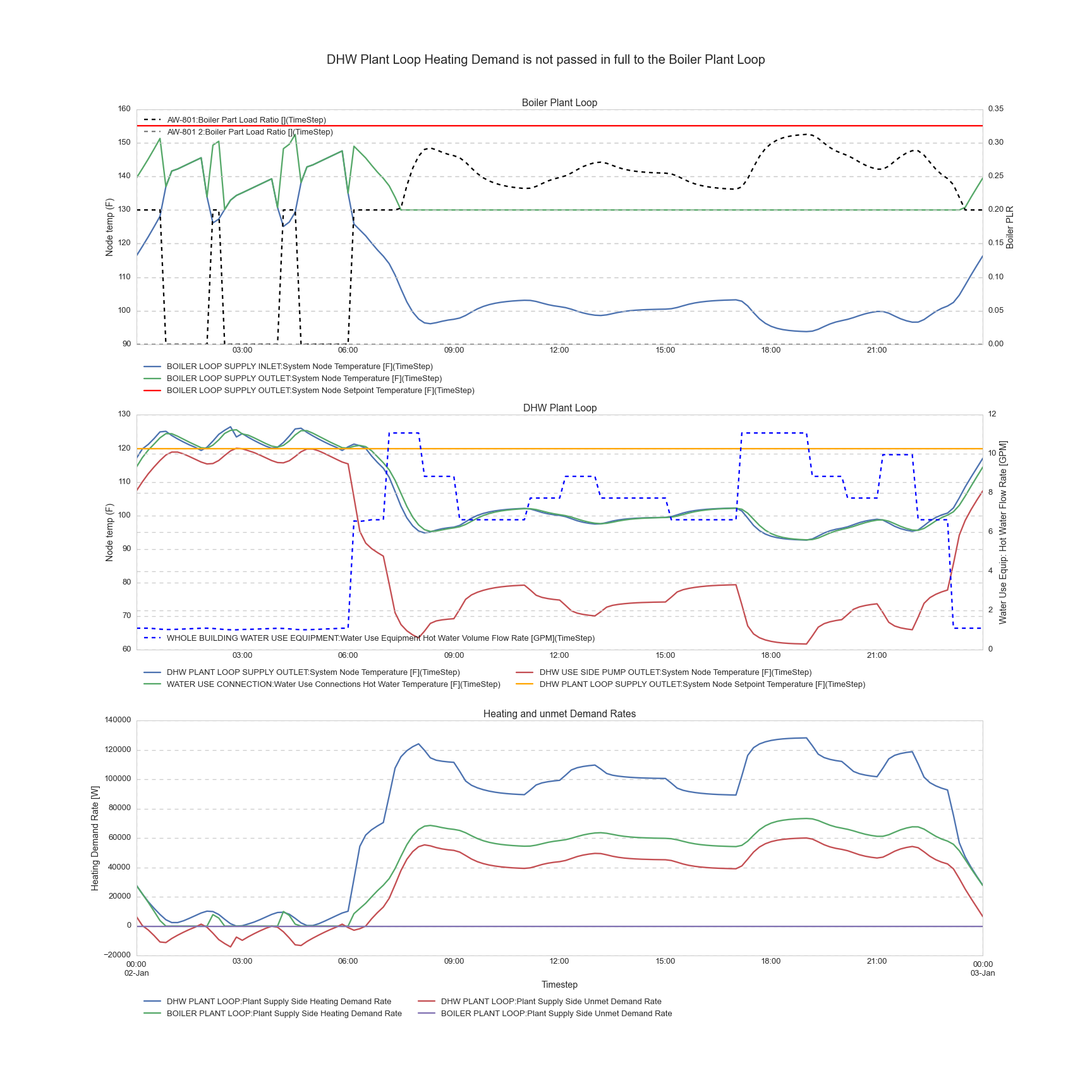

it seems that I cannot get the DHW loop (secondary) to pass its demand back to the Boiler loop (primary). Below is a graph (click on it for enlarged version) of what I'm experiencing: the DHW loop temps are NOT satisfactory, while I'm only at 30% capacity of one of my two boilers... There is Unmet Demand Rate on my DHW loop but not on my Boiler Loop.

Here is my IDF file

Details

In reality

Piping arangement

This is a primary/secondary loop arrangement. The boiler has a dedicated boiler pump, ON/OFF, constant flow, interlocked with boiler operation (typically, the pump actually starts before the boiler, and a flow switch will allow the boiler so start its ignition sequence).

The boiler feeds the tank via an internal heat exchanger: the boiler water is in the heat exchanger tubing (I guess this means source side effectiveness < 1) that is sitting in the Service Hot Water (Use Side effectiveness = 1)

The DHW loop has a recirculation pump for priming purposes only (keeping the loop at temperature to avoid drawing cold water for minutes during low load), typically only a fractional pump (less than 1HP) moving about 1 GPM per 20 fixtures (rule of thumb, ASHRAE Handbook of Fundamentals 2011, Chapter 50). It's the cold water pushing in that really moves the fluid when there's a draw on the DHW loop (from city mains pressure for low rise buildings, or for high-rise a gravity tank, booster pumps...)

There's usually a mixing valve after the tank to temper the DHW to a reasonable level, say about 120°F.

Control Sequence

There is an aquastat in the water tank that is the main variable controlling the boiler. Here is the control sequence as I understand it:

- The boiler has a Setpoint, an offset and a differential. Typical values are respectively 125°F, 5°F, and 5°F

- The boiler cut-off is at Setpoint+Offset. Typical value: 130°F. (Read: if tank reaches 130°F, boiler cuts off)

- The boiler cut-in is at Setpoint-Differential. Typical value: 120°F

- In between, the firing rate is adjusted by PID control to meet the tank setpoint.

- There are additional settings such as anti-cycle (a delay in minutes to prevent short cycling) that I'm not concerned with yet.

In EnergyPlus / Efforts so far

Plant Loops

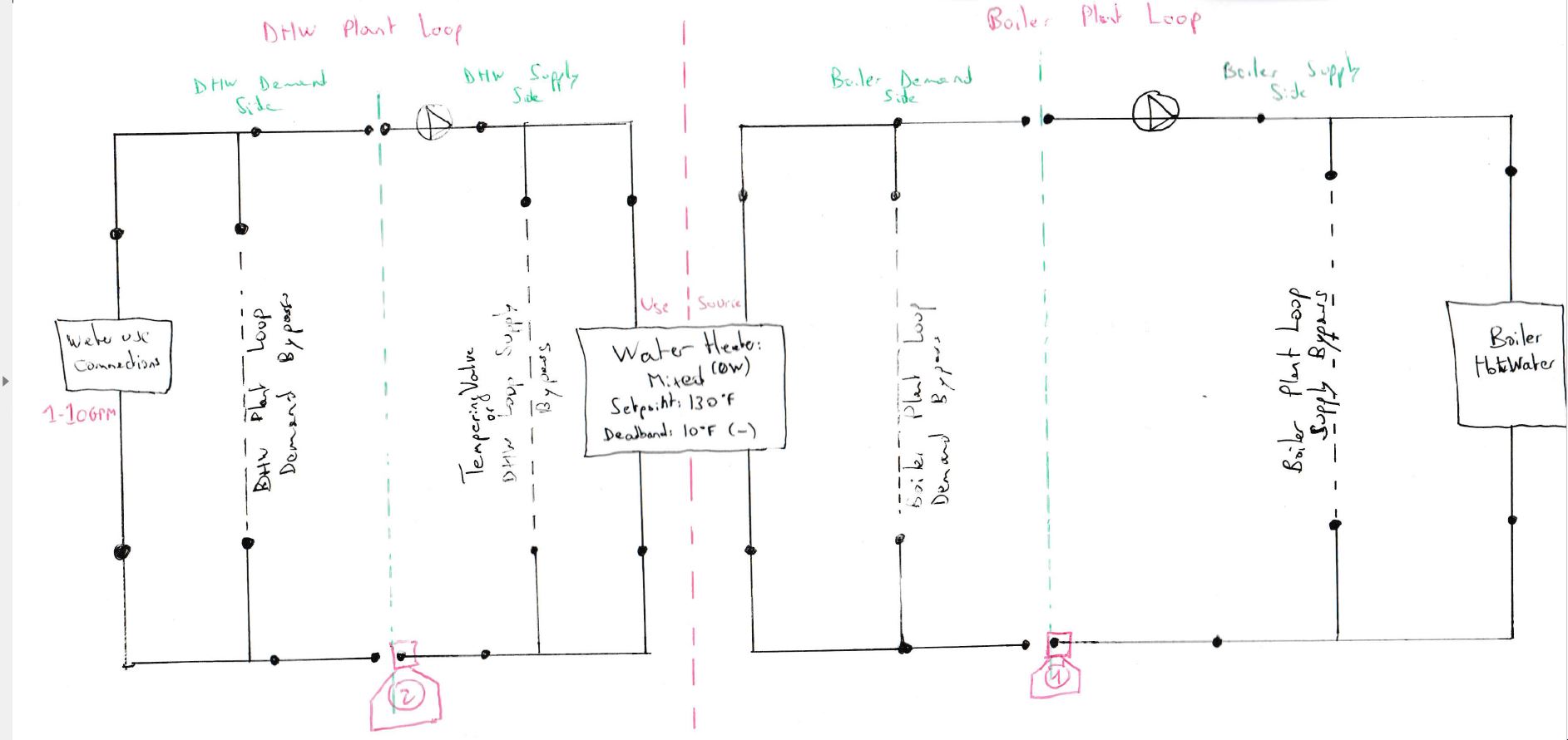

Here is the drawing of the loop as I understand it:

- The boiler pump is a

Pump:ConstantSpeedwhile the DHW pump is aPump:VariableSpeedwith a minimum flow rate corresponding to the recirculation rate (technically only the recirculation rate should have an electric consumption here, but I'm not going to care). - The boiler is a

Boiler:HotWater. - The storage tank is a

WaterHeater:Mixedwith zero ...