First time here? Check out the Help page!

| 1 | initial version |

Hi Nicole, it seems like there are two main problems: 1) Sizing is not as expected, and 2) Boiler consumption is too high.

For 1), you might need to dig into the sizing routine for the low temperature radiant object. Here is a decent starting spot in the Engineering Reference. I did not see anything glaringly wrong with your inputs. In every case I looked at, your design day schedule parameters were identical to your operational schedule parameters, so conditions are being completely influenced by outdoor and zone conditions. The zone conditions are a bit loose just because of the overall model set-up. You're not using any air loops, so once the radiant heating exceeds your single setpoints there is nothing controlling the zone temperature (this is why the zones are getting so hot). This could be having some effect on the sizing routine, but I'm not totally sure.

Ultimately the regular simulation is calling for more heating energy than the sizing calculation, which is what is causing your boiler to not be able to make its setpoint at times, which in turn means it is often maxing out at its autosized design capacity of ~15 kW. You could simply tweak your Heating Sizing Factor in Sizing:Parameters, but it may be an indication that your applied zone loads are different than what the real-life equipment was designed for. Another trick is to remove all the loads for your Winter Design Day schedule, which will increase the autosized capacity.

For 2), getting the capacity sized correctly is probably going to increase your consumption even more, which is really the main problem. You can come at this one from two different ways. Either 1) your zone loads are not high enough or 2) your real-life boiler is more efficient than the model boiler.

I'm using there term zone loads sort of broadly. This ends up being the interaction between direct zone loads (people, elec equipment and lights) and other factors like thermostat setpoint, windows and their properties and geometry surfaces and their properties. If the total interaction of those loads are low, then the radiant heating is going to work harder to make its setpoint (which is not actually controlled by the zone thermostat).

The other side is maybe the energy balance is good, but the boiler is using too much propane to make that energy. You've already got it at a nominal 95% efficiency, but that leaves you at the mercy of the DOE model in terms of varying conditions. You may want to try out some of the efficiency curves in the Boilers.idf file that is located in the DataSets folder within your energyplus installation.

You could also consider adjusting the availability of the boiler using a scheduled or HighTemperatureTurnOff availability manager on the loop.

Another strategy could be to see if a particular zone is blowing up your consumption. I noticed the kitchen and garage zones alone are using ~58% of the total consumption, so you may want to review the assumptions made there. Or maybe the radiant objects are sizing much larger than in the actual building.

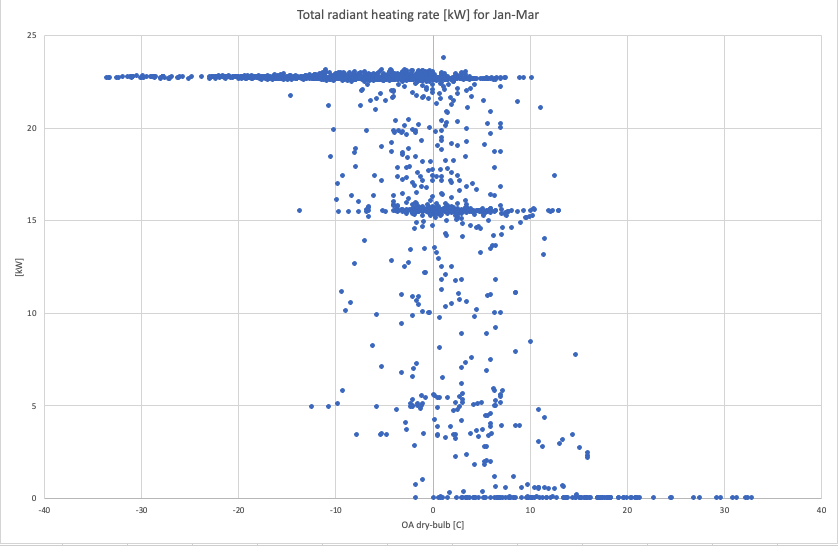

Just one last bit with regards to your comment, and I sort of briefly touched on this above, the radiant heaters are not really trying to hit an exact setpoint. They are using the zone conditions and a prescribed deadband (mean air temp and 0.56 C in your idf) to adjust water flow (check out the I/O reference link above), so depending on other loads happening in the zones, the zone temp is going to be pretty loose. In general though, the radiant heating rate seems to be behaving well, as you can see below in the comparison between total building radiant heating rate vs OA dry bulb. They are not really requesting flow above ~60F.

| 2 | No.2 Revision |

Hi Nicole, it seems like there are two main problems: 1) Sizing is not as expected, and 2) Boiler consumption is too high.

For 1), you might need to dig into the sizing routine for the low temperature radiant object. Here is a decent starting spot in the Engineering Reference. I did not see anything glaringly wrong with your inputs. In every case I looked at, your design day schedule parameters were identical to your operational schedule parameters, so conditions are being completely influenced by outdoor and zone conditions. The zone conditions are a bit loose just because of the overall model set-up. You're not using any air loops, so once the radiant heating exceeds your single setpoints there is nothing controlling the zone temperature (this is why the zones are getting so hot). This could be having some effect on the sizing routine, but I'm not totally sure.

Ultimately the regular simulation is calling for more heating energy than the sizing calculation, which is what is causing your boiler to not be able to make its setpoint at times, which in turn means it is often maxing out at its autosized design capacity of ~15 kW. You could simply tweak your Heating Sizing Factor in Sizing:Parameters, but it may be an indication that your applied zone loads are different than what the real-life equipment was designed for. Another trick is to remove all the loads for your Winter Design Day schedule, which will increase the autosized capacity.

For 2), getting the capacity sized correctly is probably going to increase your consumption even more, which is really the main problem. You can come at this one from two different ways. Either 1) your zone loads are not high enough or 2) your real-life boiler is more efficient than the model boiler.

I'm using there term zone loads sort of broadly. This ends up being the interaction between direct zone loads (people, elec equipment and lights) and other factors like thermostat setpoint, windows and their properties and geometry surfaces and their properties. If the total interaction of those loads are low, then the radiant heating is going to work harder to make its setpoint (which is not actually controlled by the zone thermostat).

The other side is maybe the energy balance is good, but the boiler is using too much propane to make that energy. You've already got it at a nominal 95% efficiency, but that leaves you at the mercy of the DOE model in terms of varying conditions. You may want to try out some of the efficiency curves in the Boilers.idf file that is located in the DataSets folder within your energyplus installation.

You could also consider adjusting the availability of the boiler using a scheduled or HighTemperatureTurnOff availability manager on the loop.

Another strategy could be to see if a particular zone is blowing up your consumption. I noticed the kitchen and garage zones alone are using ~58% of the total consumption, so you may want to review the assumptions made there. Or maybe the radiant objects are sizing much larger than in the actual building.

Just one last bit with regards to your comment, and I sort of briefly touched on this above, the radiant heaters are not really trying to hit an exact setpoint. They are using the zone conditions and a prescribed deadband (mean air temp and 0.56 C in your idf) to adjust water flow (check out the I/O reference link above), so depending on other loads happening in the zones, the zone temp is going to be pretty loose. In general though, the radiant heating rate seems to be behaving well, as you can see below in the comparison between total building radiant heating rate vs OA dry bulb. They are not really requesting flow above ~60F.

C:\fakepath\Screen Shot 2021-06-16 at 10.13.44 AM.png