| 1 | initial version |

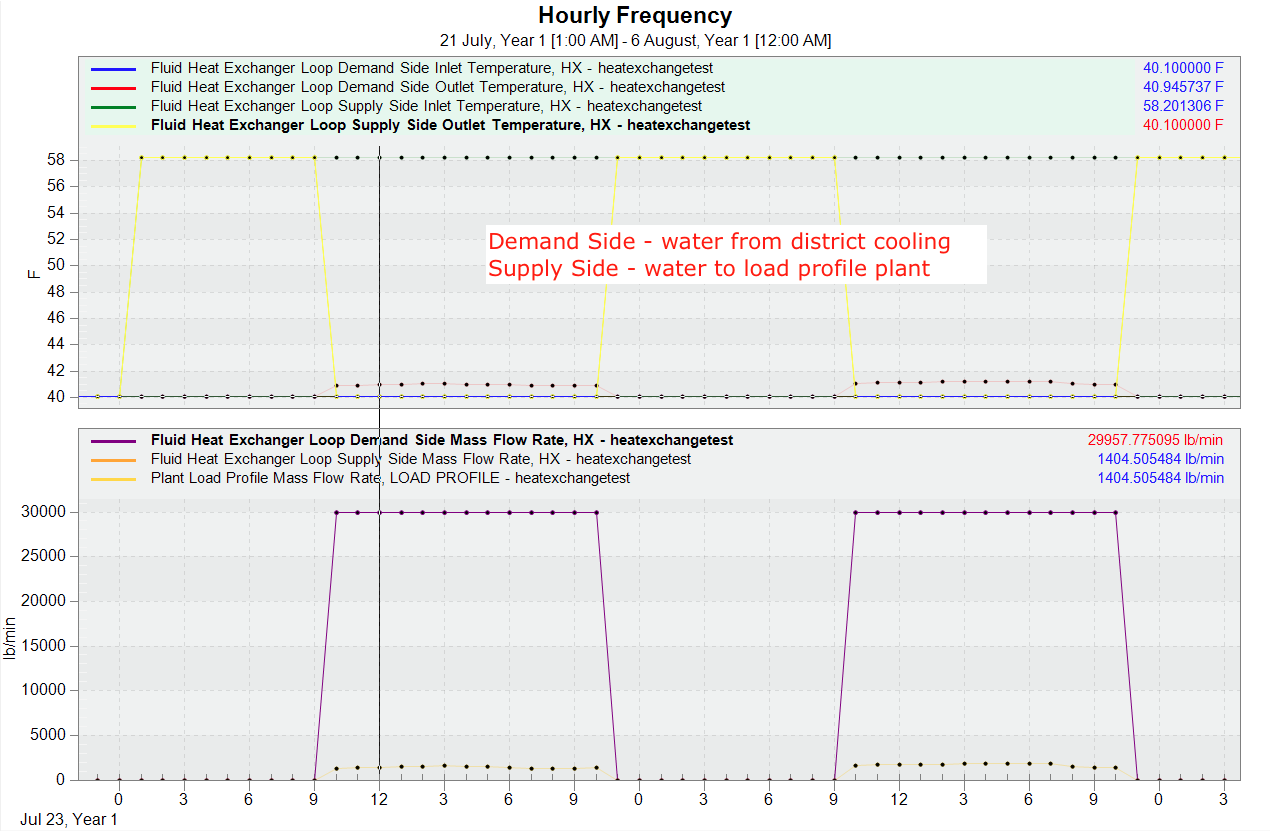

After running your IDF, you already are getting identical temperatures between supply inlet and demand outlet for the water-to-water heat exchanger (WWHX) (see below).

You are also getting the same flow rate requested by the load profile plant object on the supply side (same side of the WWHX). So it seems like your system is working as intended. The reason that you have different flow rates on the two sides of the heat exchanger is because of the different temperature differences between inlet/outlet nodes on each side (supply vs. demand) of the WWHX. Since there are two separate pumps, EnergyPlus can solve for a different flow rate in the primary loop (WWHX demand-side) due to it's different temperature difference (~0.85F in the timestep from my screenshot vs. ~18.1F for supply-side).

If you wanted to force the same flow rate on both sides of the WWHX, you would need to use EMS (looks like you've already asked about that here). Why do you want to force that?