| 1 | initial version |

I have done this with other systems and found the best method is through the use of a plant loop with a PlantComponent:TemperatureSource that a pseudo source of fluid. In your case, it would match the GSHP outlet temperatures.

You would set the PlantComponent:TemperatureSource to follow a schedule, which is controlled by a snippet like:

PlantComponent:TemperatureSource,

GSHP Plant Component Temperature Source, !- Name of water component in below loop

Node xxx, !- Inlet Node

Node xxx, !- Outlet Node

Autosize, !- Design Volume Flow Rate

Scheduled, !- Temperature Specification Type

8.0, !- Source Temperature

GSHP Water Temperature Schedule; !- Source Temperature Schedule Name

EXTERNALINTERFACE:FUNCTIONALMOCKUPUNITEXPORT:TO:SCHEDULE,

GSHP Water Temperature Schedule, !- Match the Schedule Name above

Any Number,

<Fluid Temp Variable from GSHP>, !- Variable from Dymola

0; !- Initial value

You will also want to modulate the Setpoint Manager so that the system operates:

SetpointManager:Scheduled,

Scheduled GSHP Temp, !- Name of Setpoint Manager in below loop

Temperature,

GSHP Water Temperature Schedule, !- Same schedule as above.

Node xxx;

The pump would be actuated like:

EXTERNALINTERFACE:FUNCTIONALMOCKUPUNITEXPORT:TO:ACTUATOR, !- Use a variable speed pump component

VarSpdPumpMassFlowActuator, !- This can be any name without spaces

Var Spd Pump Name, !- This is the name of pump in below loop

Pump,

Pump Mass Flow Rate,

<Fluid mass flow rate from GSHP>, !- This is the name of the variable from Dymola

0; !- Initial value

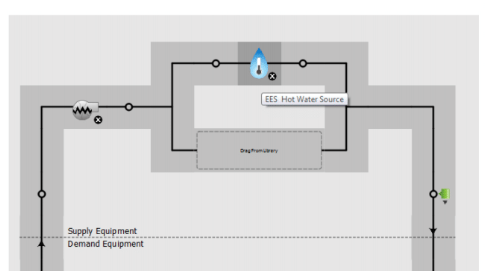

The loop will look something like:

| 2 | No.2 Revision |

I have done this with other systems and found the best method is through the use of a plant loop with a PlantComponent:TemperatureSource that acts as a pseudo source of fluid. In your case, it would match the GSHP outlet temperatures.

You would set the PlantComponent:TemperatureSource to follow a schedule, which is controlled by a snippet like:

PlantComponent:TemperatureSource,

GSHP Plant Component Temperature Source, !- Name of water component in below loop

Node xxx, !- Inlet Node

Node xxx, !- Outlet Node

Autosize, !- Design Volume Flow Rate

Scheduled, !- Temperature Specification Type

8.0, !- Source Temperature

GSHP Water Temperature Schedule; !- Source Temperature Schedule Name

EXTERNALINTERFACE:FUNCTIONALMOCKUPUNITEXPORT:TO:SCHEDULE,

GSHP Water Temperature Schedule, !- Match the Schedule Name above

Any Number,

<Fluid Temp Variable from GSHP>, !- Variable from Dymola

0; !- Initial value

You will also want to modulate the Setpoint Manager so that the system operates:

SetpointManager:Scheduled,

Scheduled GSHP Temp, !- Name of Setpoint Manager in below loop

Temperature,

GSHP Water Temperature Schedule, !- Same schedule as above.

Node xxx;

The pump would be actuated like:

EXTERNALINTERFACE:FUNCTIONALMOCKUPUNITEXPORT:TO:ACTUATOR, !- Use a variable speed pump component

VarSpdPumpMassFlowActuator, !- This can be any name without spaces

Var Spd Pump Name, !- This is the name of pump in below loop

Pump,

Pump Mass Flow Rate,

<Fluid mass flow rate from GSHP>, !- This is the name of the variable from Dymola

0; !- Initial value

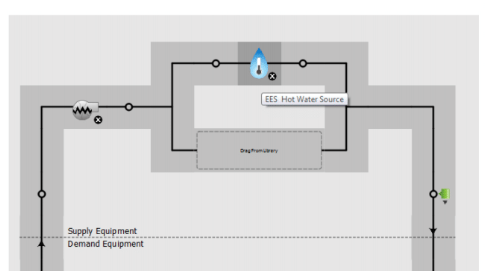

The loop will look something like: